Novel tobacco furnace

A flue-cured tobacco, a new type of technology, applied in the direction of tobacco, tobacco preparation, application, etc., can solve the problems of poor sealing effect, trees being felled, affecting the quality of flue-cured tobacco, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

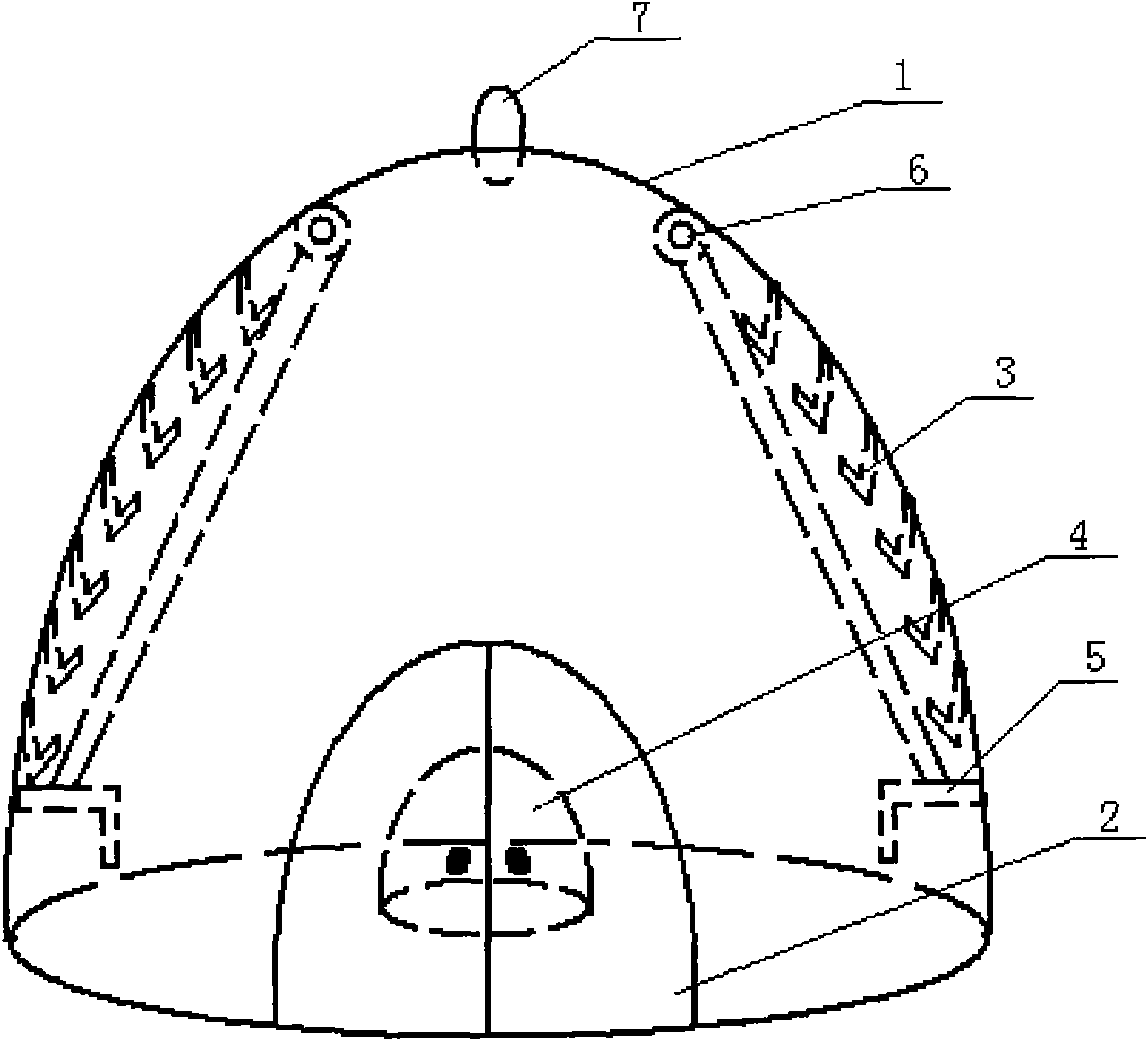

[0010] like figure 1 As shown, a novel flue-cured tobacco furnace comprises a furnace body 1, a furnace door 2 and a hook 3, a fuel chamber 4 is provided in the furnace body 1, a handle 5, a pulley 6 and a hook 3 are arranged on the inner wall of the furnace body 1, and the pulley 6 is connected with crank handle 5 by rope, and the outer top of body of heater 1 is provided with automatic alarm 7.

[0011] When in use, first open the furnace door 2, put the ignited coal into the fuel chamber 4, send the tobacco leaves to be roasted to the hook 3 on the inner wall of the furnace body 1 through the crank handle 5 and pulley 4, and finally close the furnace door 2, and the tobacco leaves Just carry out baking under the sealed condition, when the tobacco leaves are baked, the automatic alarm 7 sends an alarm sound, and the furnace door 2 can be opened, and the tobacco leaves that have been baked are taken out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com