A curing method for improving protein degradation rate of tobacco leaves

A curing method and technology of degradation rate, applied in the field of flue-cured tobacco curing, can solve the problem that Maillard reaction cannot proceed well, and achieve the effects of prolonging the degradation time of high enzymatic activity, ensuring supply and improving the degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

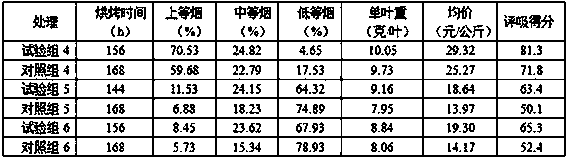

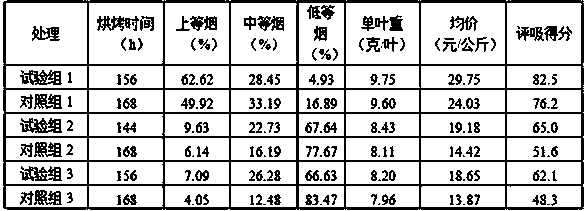

Examples

Embodiment 1

[0033] A roasting method for improving the degradation rate of tobacco leaf protein, comprising the following steps:

[0034] A. Harvesting: Harvesting fresh tobacco leaves of the K326 variety that are suitable for ripening.

[0035] B. Tobacco weaving: same rod, same quality, same part, appropriate density;

[0036] C. Furnace loading: put the tobacco leaves collected in step A into the barn, with the same quality as the furnace, and fill them all up;

[0037] D. Yellowing: including early yellowing, mid-yellowing and late yellowing. In the early stage of yellowing, the dry bulb temperature is raised from 27°C to 34°C at a heating rate of 1.5°C / h, and the wet bulb temperature is adjusted from 26°C. To 33°C, stabilize the dry and wet bulb temperatures, and bake for 16 hours; then enter the mid-yellowing period, with a heating rate of 1.5°C / 1~2h, raise the dry bulb temperature to 38°C, and adjust the wet bulb temperature to 35°C (the The endopeptidase activity for degrading p...

Embodiment 2

[0041] A roasting method for improving the degradation rate of tobacco leaf protein, comprising the following steps:

[0042] A. Harvesting: Harvesting fresh tobacco leaves of the K326 variety that are suitable for ripening.

[0043] B. Tobacco weaving: same rod, same quality, same part, appropriate density;

[0044] C. Furnace loading: put the tobacco leaves collected in step A into the barn, with the same quality as the furnace, and fill them all up;

[0045] D. Yellowing: including early yellowing, middle yellowing and late yellowing. In the early yellowing, the dry bulb temperature is raised from 28°C to 36°C at a heating rate of 1.5°C / h, and the wet bulb temperature is adjusted from 27°C. to 34°C, stabilize the dry and wet bulb temperatures, and bake for 18 hours; then enter the mid-yellowing period, raise the dry bulb temperature to 38°C at a heating rate of 1.5°C / 2h, and adjust the wet bulb temperature to 35°C (the temperature drops The endopeptidase activity of prote...

Embodiment 3

[0049] A roasting method for improving the degradation rate of tobacco leaf protein, comprising the following steps:

[0050] A, harvesting: harvest suitable ripe K326 variety fresh tobacco leaves; described fresh tobacco leaves are leaves in the middle of the tobacco plant; described suitable ripeness is specifically shown as light yellow leaf color of tobacco leaves, main veins are all white and shiny, and branch veins turn white, Leaf tips and leaf margins roll down, leaf surfaces are wrinkled, with mature spots, and most of the hairs fall off;

[0051] B. Rod weaving and furnace loading: Weaving the harvested tobacco leaves into the barn and waiting for baking; the principle of weaving the rods is that the same rods are of the same quality, the same position, and the density is appropriate; The principle of furnace loading is that the same furnace is of the same quality, and the furnace is fully filled; the smoke density of the barn mentioned above is 42 kg / m 3 , smoke to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com