Flue-cured tobacco flue-curing barn control system and control method thereof

A control system and curing room technology, applied in the field of flue-cured tobacco curing, can solve the problems of low efficiency and environmental pollution of coal-fired tobacco leaves, and achieve the effects of improving the quality of flue-cured tobacco, reducing labor costs, and reducing air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

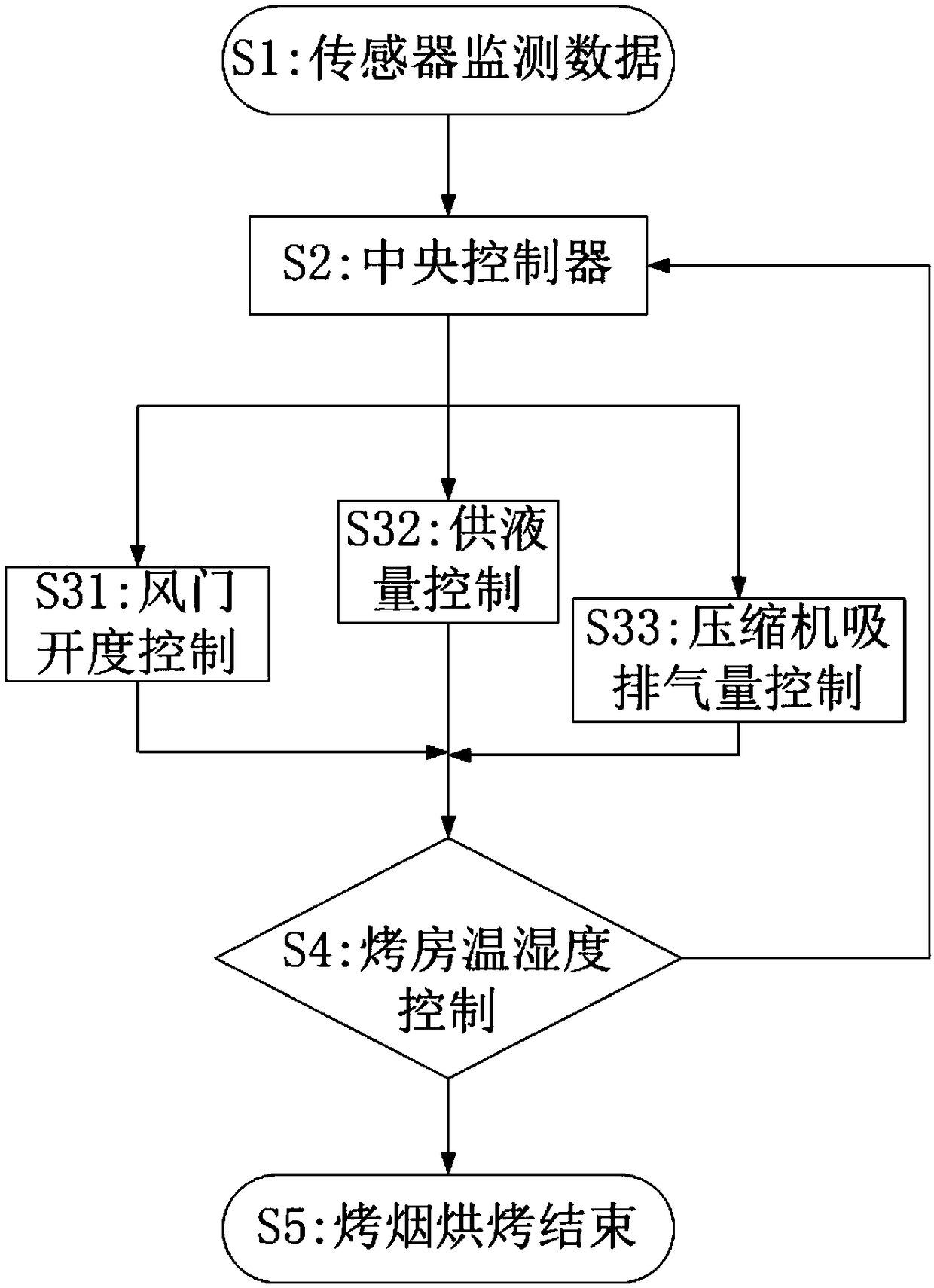

[0067] The present application will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

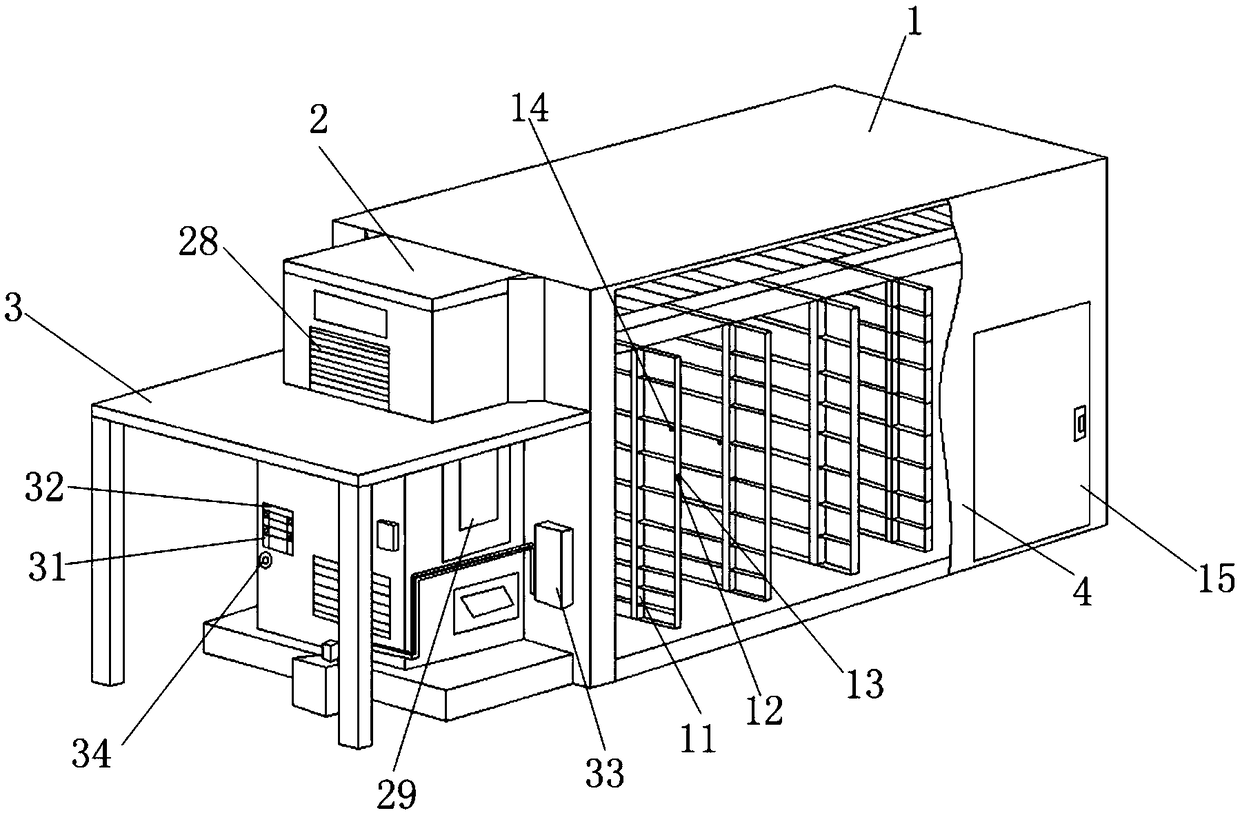

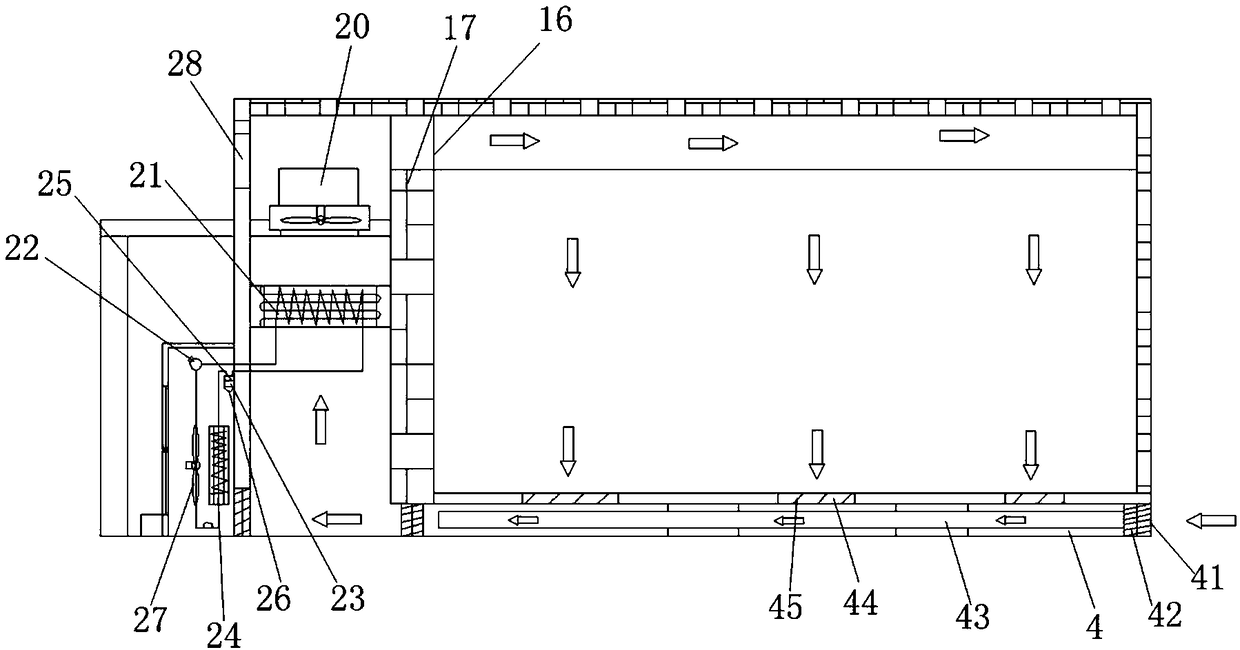

[0068] Such as figure 1 with figure 2 As shown, the embodiment of the present application provides a flue-cured tobacco curing room control system, which includes: a curing room 1; a heat pump unit room 2; a retaining wall 3; a dehumidification channel 4; Below, the baking room 1 is adjacent to the pump unit room 2; the retaining wall 3 is set horizontally;

[0069] The baking room 1 is also provided with a cigarette rack 11; a temperature sensor 12; a humidity sensor 13; a video camera 14; a barn door 15; a barn air inlet 16; They are respectively arranged on the cigarette racks 11; the air inlet 16 of the barn is connected to the barn room 1 and the heat pump unit room 2; the heat insulation wall 17 separates the barn room 1 from the heat pump unit room 2;

[0070]The heat pump unit room 2 includes a blower 20; a conde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com