A pretreatment method and pretreatment tool for tobacco leaves before roasting

A pretreatment and tool technology, applied in the treatment of tobacco, tobacco, application, etc., can solve the problems of low efficiency of main vein removal, unfavorable quality, polyphenol oxidation, etc., to improve the quality of flue-cured tobacco, avoid cell damage, and quickly remove Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

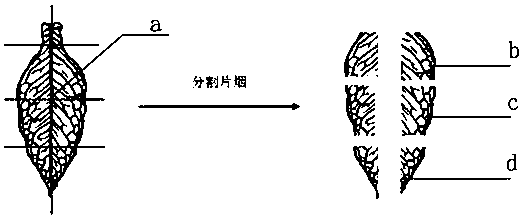

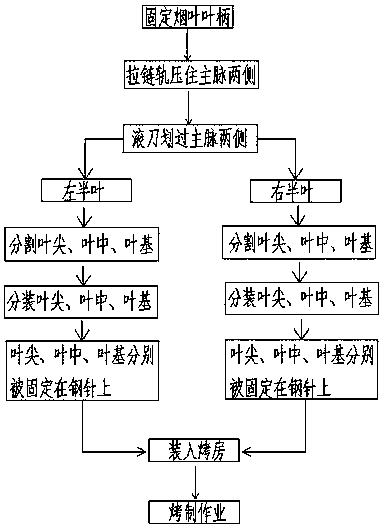

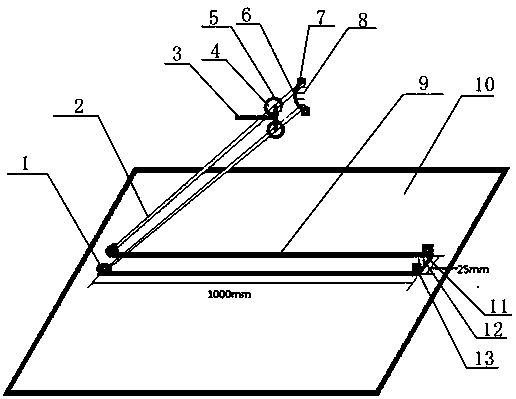

[0046] Such as Figure 1-7 as shown, figure 1 It is a schematic diagram of blade division of the present invention. figure 2 It is a schematic diagram of the pretreatment flow chart of the present invention. image 3 It is a structural schematic diagram of the main vein removing tool of the present invention. Figure 4 It is a schematic partial side view of the aortic removal tool of the present invention. Figure 5 It is a structural schematic diagram of the box body of the smoking tool of the present invention. Figure 6 It is a structural schematic diagram of the box cover of the cigarette filling tool of the present invention. Figure 7 It is a partial structural diagram of the insertion rod part of the box cover of the present invention.

[0047] The invention discloses a pretreatment method before tobacco leaves are roasted, wherein the pretreatment method uses a special main vein removal tool and a tobacco filling tool, and the operation steps are as follows:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com