Multi-stage sorting device for mechanically picking fresh tea leaves

A technology of mechanical picking and fresh tea leaves, which is applied in solid separation, tea treatment before extraction, and separation of solids from solids by air flow, etc. The effect of improving the quality of tea grade, increasing the output and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

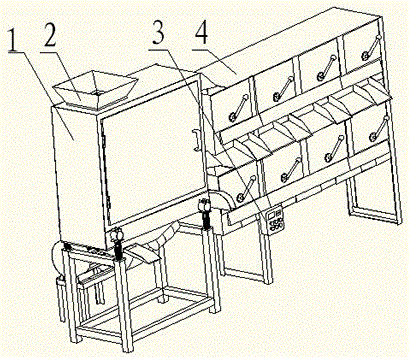

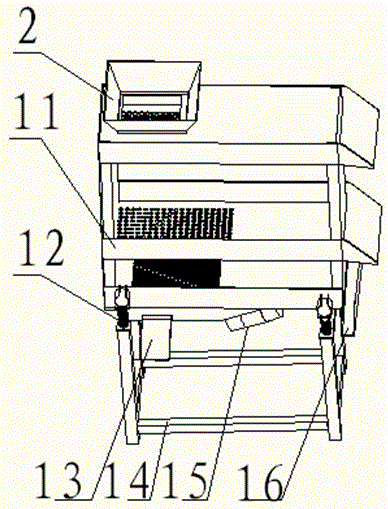

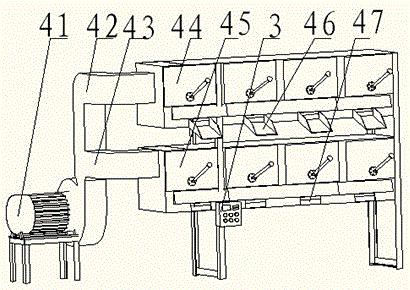

[0010] Such as figure 1 As shown, the multi-stage sorting device for mechanically picked fresh tea leaves of the present invention includes a fresh tea leaves winnowing part 4, a fresh tea leaves vibrating screening part 1, a feed hopper 2, and an electrical control box 3. Press the start button on the electrical control box 3, pour the picked fresh tea leaves into the feed hopper 2, pass through the screen mesh in the fresh tea leaf vibrating screening part 1, and evenly fall into the fresh tea leaves from the outlet of the vibrating sieve box. In the two groups of bellows of the leaf winnowing part 4, the fresh tea leaves are further graded and screened under the action of wind force. Such as figure 2 As shown, the fresh tea leaves vibratory screening unit 1 includes a vibrating screen box 11, two vibrating motors 15 installed on the bottom of the vibrating screen box 11, a bracket assembly 14 supporting the vibrating screen box 11, and the bracket assembly 14 and the vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com