Walnut kernel grading method and walnut kernel grading device based on machine vision

A technology of machine vision and grading method, which is applied in the direction of instruments, sorting, computer parts, etc., and can solve problems such as high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

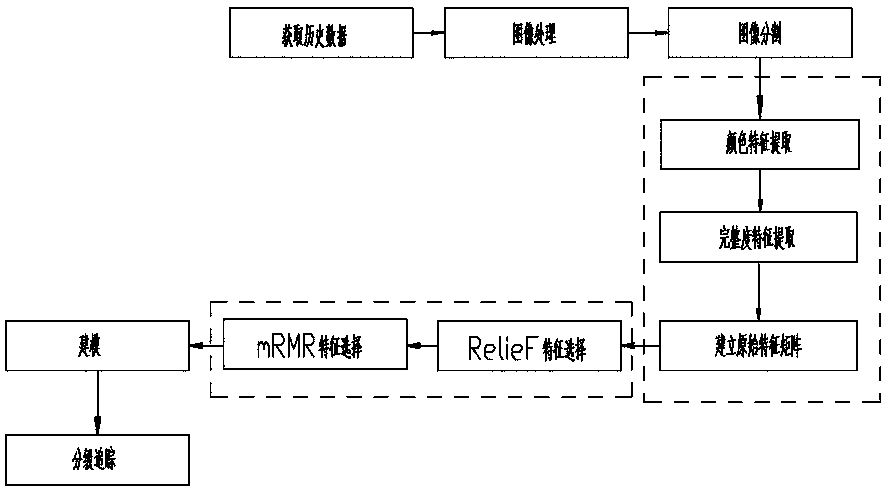

[0071] Embodiment 1: as attached figure 1 Shown, the walnut kernel grading model construction method of machine vision grading equipment, its steps are as follows:

[0072] The first step: as attached figure 1 As shown, to obtain historical sample data, the specific operation is as follows:

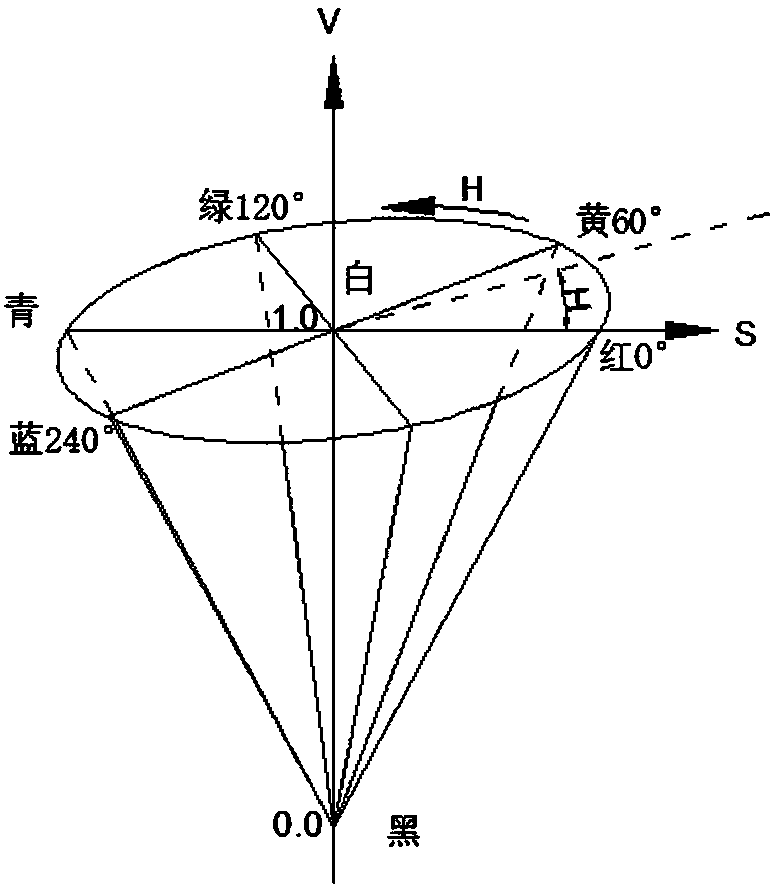

[0073] Through manual grading, obtain the historical data of 30 walnut kernel samples of the five grades (such as Table 2-1 walnut kernel grades) of the first grade, second grade, third grade, fourth grade and other grades; Each walnut kernel sample is sent to the machine vision equipment through the conveying platform; among them, the camera passing through the machine vision equipment needs to perform white balance correction, and blue can be initially selected as the background color of the single image acquired by the camera, which can increase the distance between the target color and the North The background color gap increases the segmentation effect;

[0074] The second step: a...

Embodiment 2

[0188] Embodiment 2: as attached Figure 13 Shown, a kind of walnut kernel grading device based on machine vision-based walnut kernel grading method and walnut kernel grading device includes mobile platform 1, machine vision equipment, controller 5, pushing mechanism and classification discharge trough; On mobile platform 1 Machine vision equipment is housed on it, and machine vision equipment comprises light box 2, camera 3 and PC host 4; Camera 3 is positioned at light box 2, and is electrically connected with PC host 4; PC host 4 is electrically connected with described controller 5; The box 2 is fixedly installed on the upper end of the platform frame of the mobile platform 1; the left side entrance 6 and the right side exit 7 are provided on the light box 2 along the direction of the mobile platform 1; the rear side of the mobile platform 1 in the light box 2 is spaced along the left and right At least two grading discharge troughs are fixed, and a push mechanism that can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com