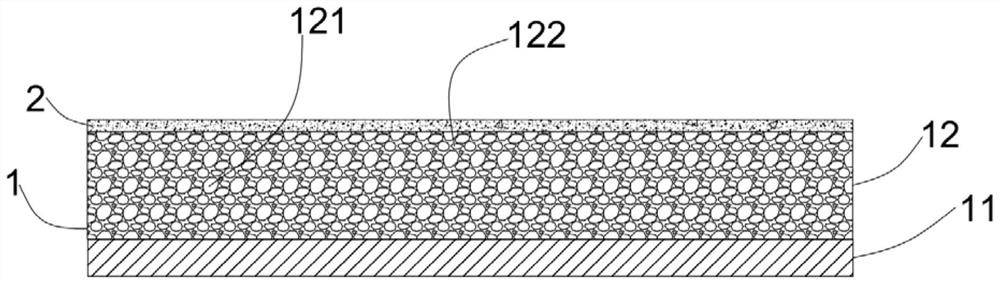

Chemical thermal insulation composite film and preparation process thereof

A technology of thermal insulation and preparation technology, which is applied in the field of composite membranes, can solve the problems of lowering production efficiency and increasing the thickness of composite membranes, and achieves the effects of reducing usage, increasing thickness, and enhancing thickness and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0143] A preparation process of chemical thermal insulation composite film, comprising the steps of:

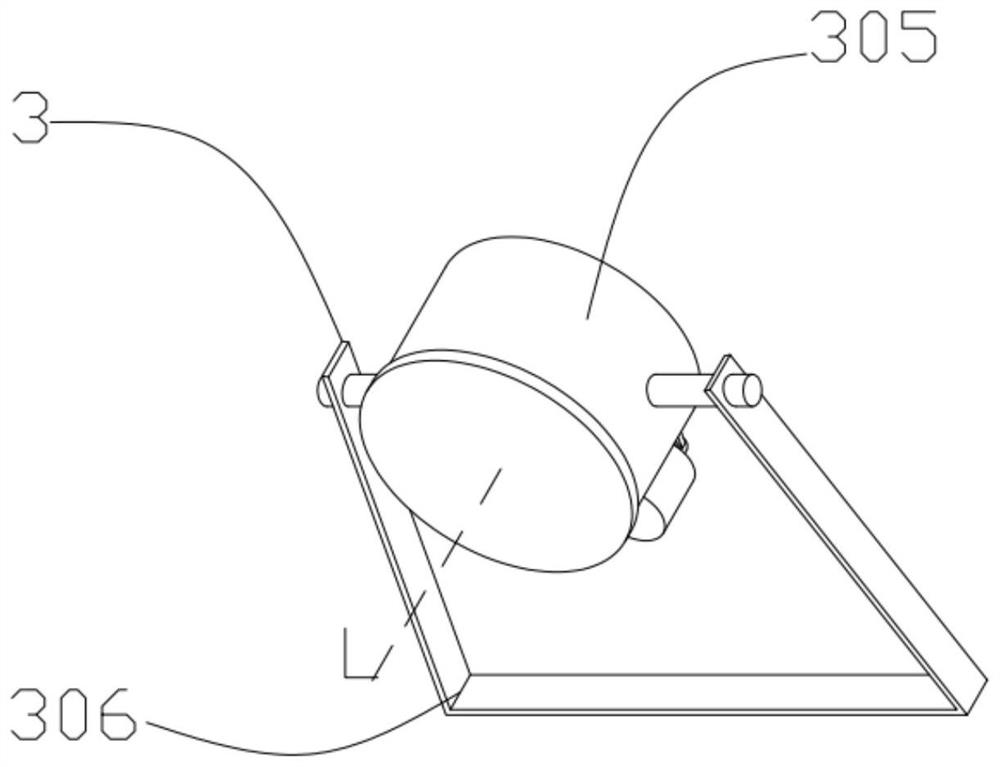

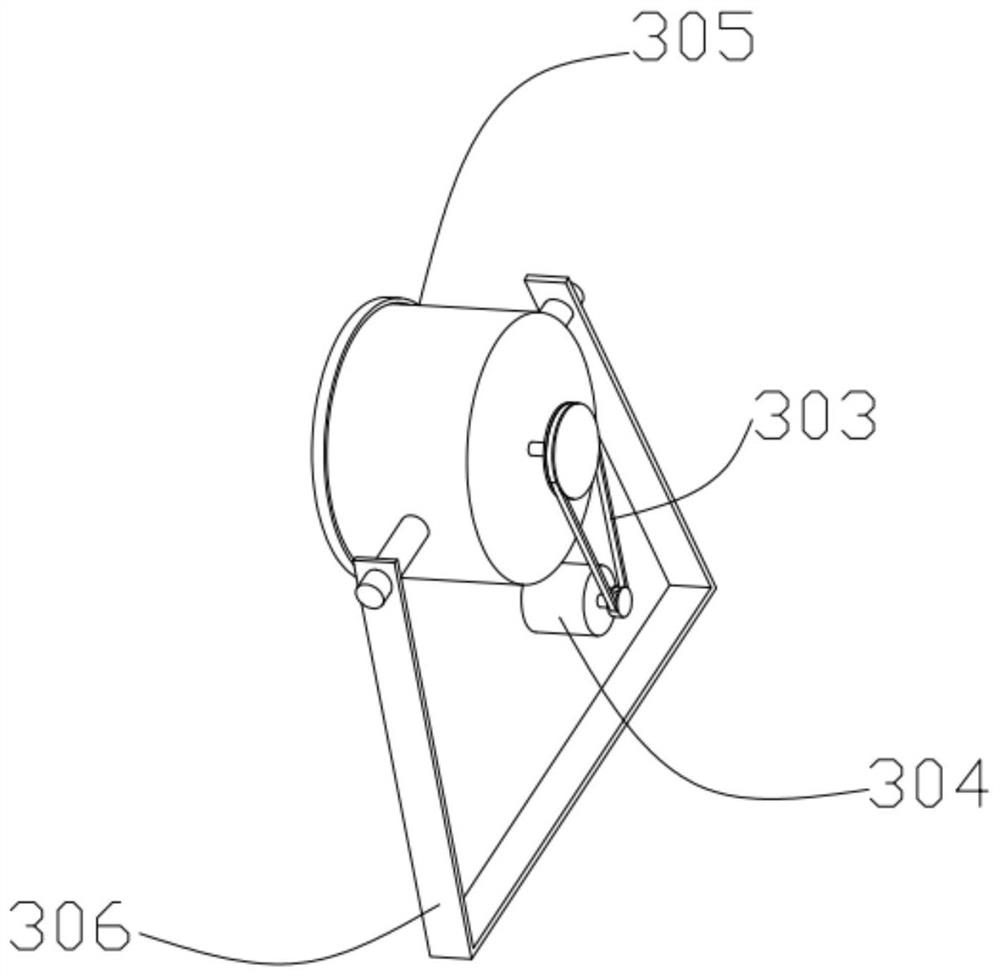

[0144] S1, take 0.05 parts by weight of foaming agent composite powder, add the foaming agent composite powder into the sieve drum 301 of the classification mixing device 3, and then divide 0.2 parts by weight of the porous inorganic particles into two Parts, respectively added in the sieve cylinder 301 and between the sieve cylinder 301 and the working chamber 302, and added the broken beads 307 into the cavity between the sieve cylinder 301 and the working chamber 302; The sieve drum 301 and the working bin 302 are rotated to a horizontal position, and the driving device 304 is started to drive the sieve drum 301 and the working bin 302 to rotate around the central axis synchronously. 500 revolutions per minute, rotate for 5 minutes; after the rotation stops, rotate the sieve cylinder 301 and the working chamber 302 to the position where the opening is inclined downward, an...

Embodiment 2

[0149] A preparation process of chemical thermal insulation composite film, comprising the steps of:

[0150] S1, taking 5 parts by weight of foaming agent composite powder, adding the foaming agent composite powder into the sieve drum 301 of the classification mixing device 3, and then dividing 5 parts by weight of the porous inorganic particles into two Parts, respectively added in the sieve cylinder 301 and between the sieve cylinder 301 and the working chamber 302, and added the broken beads 307 into the cavity between the sieve cylinder 301 and the working chamber 302; The sieve drum 301 and the working bin 302 are rotated to a horizontal position, and the driving device 304 is started to drive the sieve drum 301 and the working bin 302 to rotate around the central axis synchronously. 2000 revolutions per minute, rotate for 3 minutes; after the rotation stops, rotate the sieve cylinder 301 and the working chamber 302 to the position where the opening is inclined downward,...

Embodiment 3

[0155] A preparation process of chemical thermal insulation composite film, comprising the steps of:

[0156] S1, taking 3 parts by weight of foaming agent composite powder, adding the foaming agent composite powder into the sieve drum 301 of the classification mixing device 3, and then dividing 3 parts by weight of the porous inorganic particles into two parts Parts, respectively added in the sieve cylinder 301 and between the sieve cylinder 301 and the working chamber 302, and added the broken beads 307 into the cavity between the sieve cylinder 301 and the working chamber 302; The sieve drum 301 and the working bin 302 are rotated to a horizontal position, and the driving device 304 is started to drive the sieve drum 301 and the working bin 302 to rotate around the central axis synchronously. 1200 revolutions per minute, rotate for 4 minutes; after the rotation stops, rotate the sieve cylinder 301 and the working chamber 302 to the position where the opening is inclined dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com