Method for improving quality of tobacco leaves by lysobacter sp

A kind of technology of lysobacteria and tobacco leaves, applied in the field of tobacco alcoholization and fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] ——The application of Lysobacterium C8-1 in improving the quality of tobacco leaves, the specific steps are as follows:

[0024] (1) Slant culture: medium: glucose 0.5g; yeast extract 0.5g; peptone 0.5g; acid hydrolyzed casein 0.5g; soluble starch 0.5g; sodium pyruvate 0.3g; g; agar 15g; distilled water 1000mL, pH7.2; culture temperature is 30°C, culture time is 7d.

[0025] (2) Seed culture: pick part of the mycelium from the slope and put it into the seed liquid, and shake the flask for 36 hours. Seed medium: dextrin 120g; soybean powder 40g; yeast extract 2g; tryptophan 0.5g; β-alanine 5g; magnesium sulfate 0.5g; ammonium phosphate 0.2g; ℃.

[0026] (3) Fermentation culture: Inoculate 10% of the inoculum into the fermentation medium, and culture in shake flasks for 6 days. Medium: soybean powder 10g; glucose 10g; peptone 3g; sodium chloride 2.5g; calcium carbonate 2g;

[0027] (4) Take 1L of the fermentation culture solution, centrifuge at 3500r / min for 10min, rem...

Embodiment 2

[0044] Repeat Example 1, with the following differences: the treatment concentration is 20 mL per 1 kg of shredded tobacco sprayed with bacterial dose.

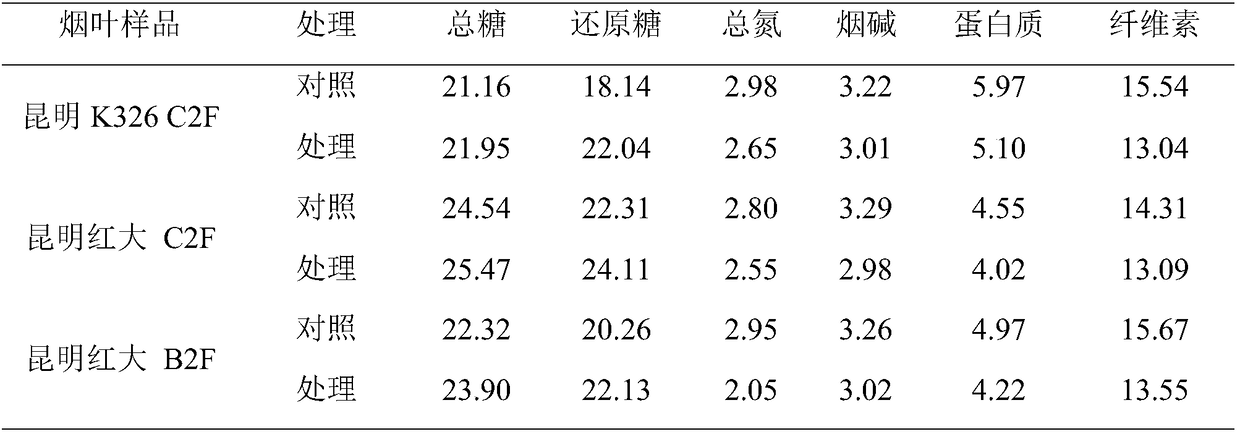

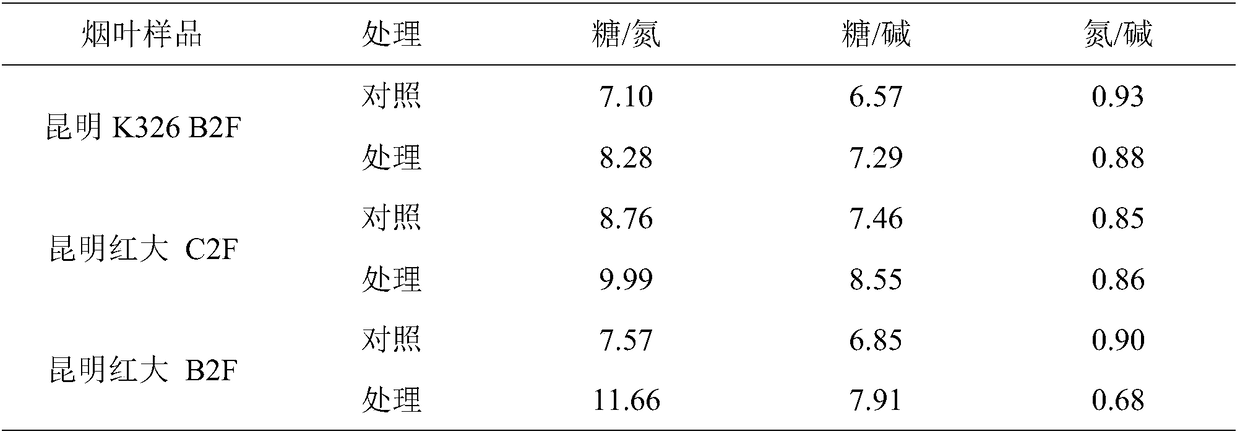

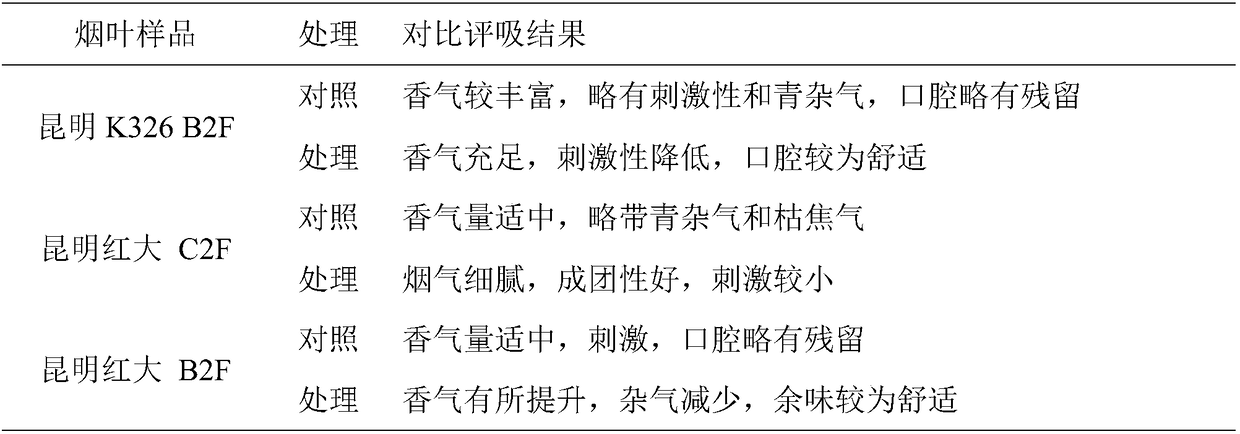

[0045] ——Chemical Composition Determination Results

[0046] The test results of the chemical components of the tobacco leaves are as follows (see Tables 4 and 5 for details). The experimental results show that, from the perspective of a single compound, the internal chemical components of the tobacco leaves treated with the bacterial agent have changed significantly. Compared with the control, the content of total sugar and reducing sugar increased greatly, and the content of total nitrogen, cellulose, protein and nicotine decreased compared with the control. Sugar-to-nitrogen ratio, sugar-to-base ratio, and nitrogen-to-base ratio all improved. The systematic test data shows that all kinds of shredded tobacco treated with bacterial agents are better than the control, and the components in the shredded tobacco tend to be bal...

Embodiment 3

[0057] Repeat Example 1, with the following differences: the treatment concentration is 30 mL per 1 kg of shredded tobacco sprayed with bacterial dose.

[0058] ——Chemical Composition Determination Results

[0059] The test results of the chemical components of the tobacco leaves are as follows (see Tables 7 and 8 for details). The experimental results show that, from the perspective of a single compound, the internal chemical components of the tobacco leaves treated with the bacterial agent have changed significantly. Compared with the control, the content of total sugar and reducing sugar increased greatly, and the content of total nitrogen, cellulose, protein and nicotine decreased compared with the control. Sugar-to-nitrogen ratio, sugar-to-base ratio, and nitrogen-to-base ratio all improved. The systematic test data shows that all kinds of shredded tobacco treated with bacterial agents are better than the control, and the components in the shredded tobacco tend to be bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com