Preparation method of premixed raw material of ferrite magnet presintering material

A technology of permanent magnet ferrite and pre-sintered material, which is applied in the preparation of pre-mixed raw materials for permanent ferrite pre-sintered material, and in the field of raw material production for wet production of permanent ferrite pre-sintered material, which can solve the problem of mechanical footprint. It can reduce the labor intensity, improve the working environment and reduce the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

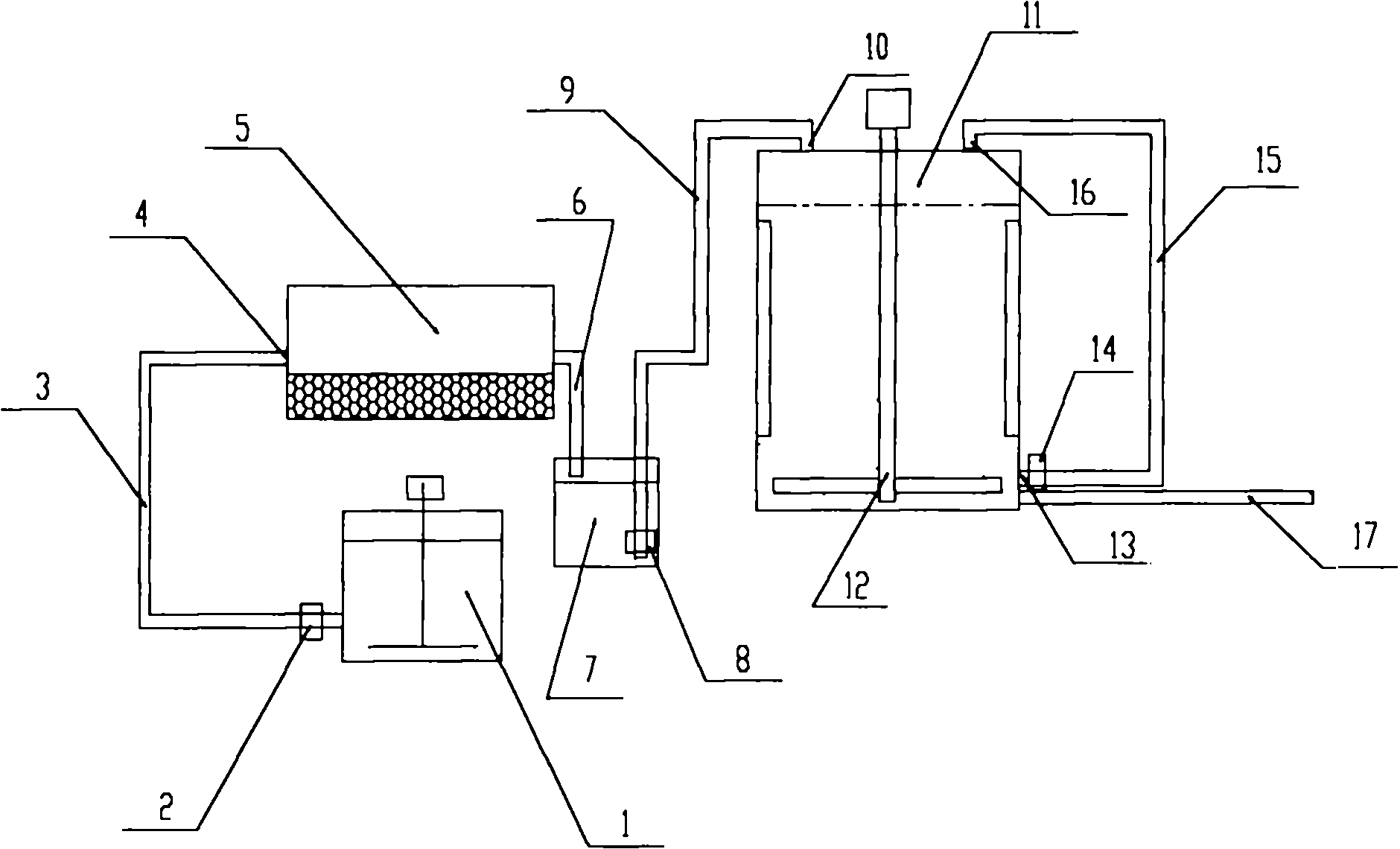

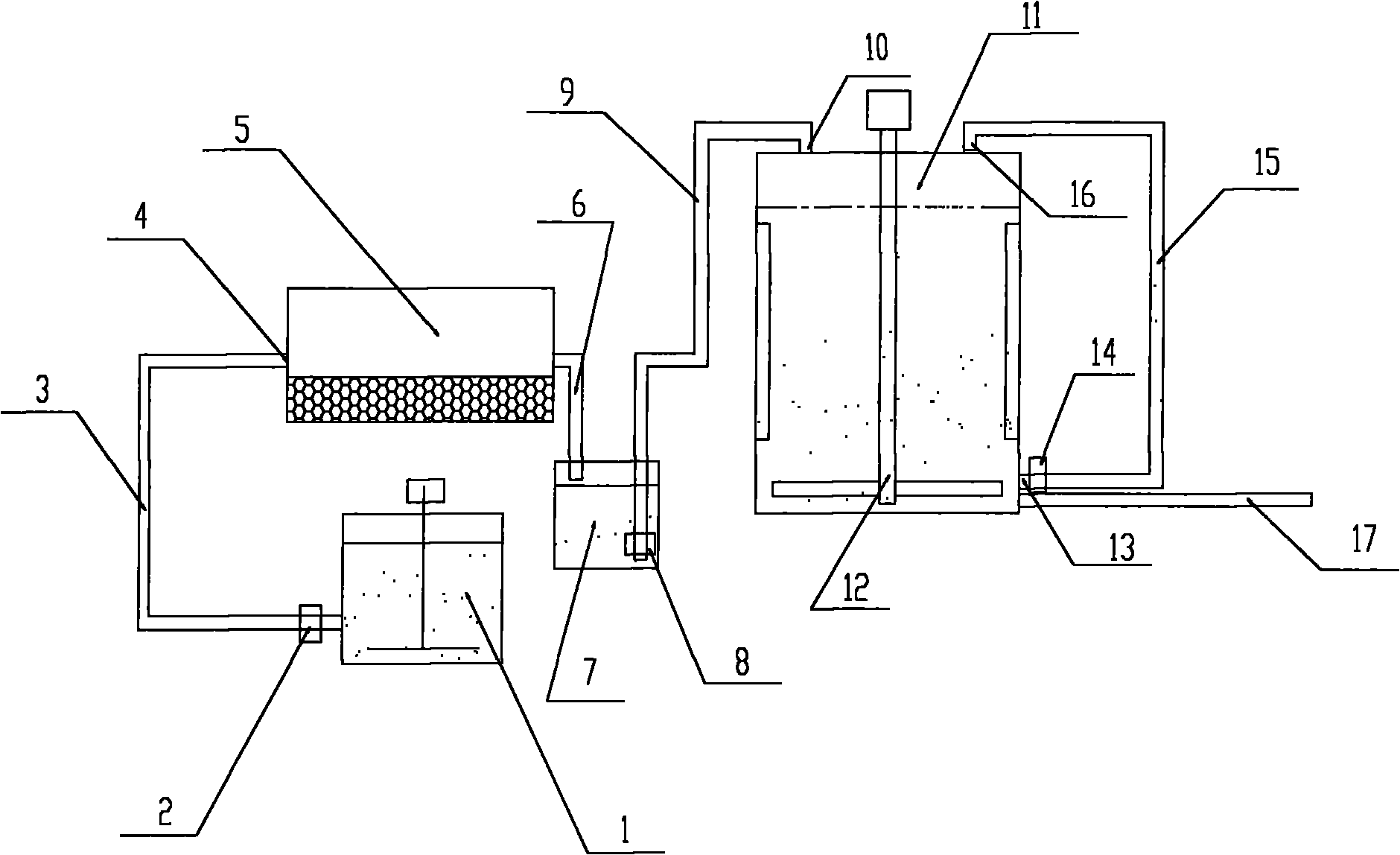

[0020] 1. Iron oxide red coarse material, strontium carbonate, and water are mixed according to the process ratio, poured into pit mixer 1, and mixed for 1 hour;

[0021] 2. The mixed slurry is transported to the barrel mill 4 by the pump 2 and the delivery pipeline 3 for grinding. The barrel mill is equipped with steel balls according to different raw materials, and the grinding particle size is controlled by the feeding amount.

[0022] 3. The material with a qualified particle size after grinding is stored in the storage tank 7, and is transported to the large-capacity precision control tank 10 through the pump 8, the delivery pipeline 9, and the feed port 11 of the precision control tank. The slurry circulation pipeline 13, coupled with the stirring of the tank wall ribs of the large-capacity precise control tank 10, fully stirs and homogenizes the slurry.

[0023] 4. Use an X-ray fluorescence analyzer to analyze the composition of the slurry in the agitated storage tank, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com