Transmission structure of cylindrical counter-bore classifying screen for corn seeds

A technology of transmission structure and grading sieve, which is applied in the direction of filter sieve, solid separation, grille, etc., can solve the problems of difficulty in replacing the cylinder sieve, troublesome use, and many fault points, etc., to achieve easy grading, wide application, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

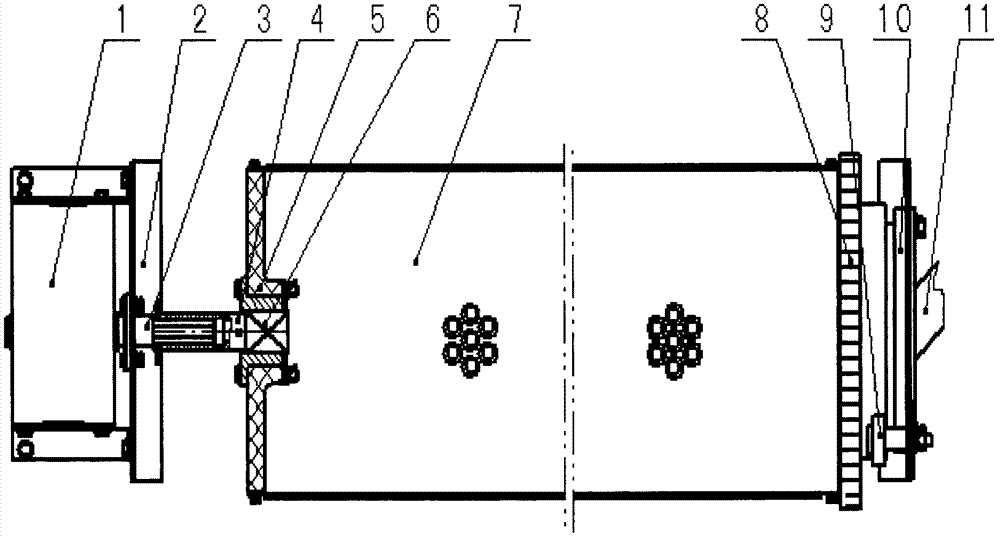

[0015] like figure 1 As shown, a transmission structure of a cylindrical countersunk hole corn seed grading screen includes a reducer 1 with a motor, a body 2, a cylindrical countersunk hole screen 7 and a feeding pipe 11.

[0016] The cylindrical countersunk screen 7 is set in the body 2, its feed end is fixed on the fixed ring 8 on one side of the body 2, and its discharge end is fixed on the fixed plate 5 on the other side of the body 2; one side of the body 2 There is a reducer 1; one side of the cylindrical countersunk screen 7 is provided with a connecting shaft 4, which is connected with the reducer 1 through the reducer shaft 3; the fixing plate 5 is provided with a fixing sleeve 6; the fixing ring 8 passes through The support roller 9 is connected with an inner material guide port 10 , and the inner material guide port 10 is connected with the feed pipe 11 .

[0017] The cylindrical wall of the cylindrical countersunk screen 7 is composed of holes of standard specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com