Titanium dioxide concentration process

A technology, titanium dioxide technology, applied in the field of titanium dioxide production, can solve problems such as acidic semi-dehydration and easy-to-corrosion concentration system equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

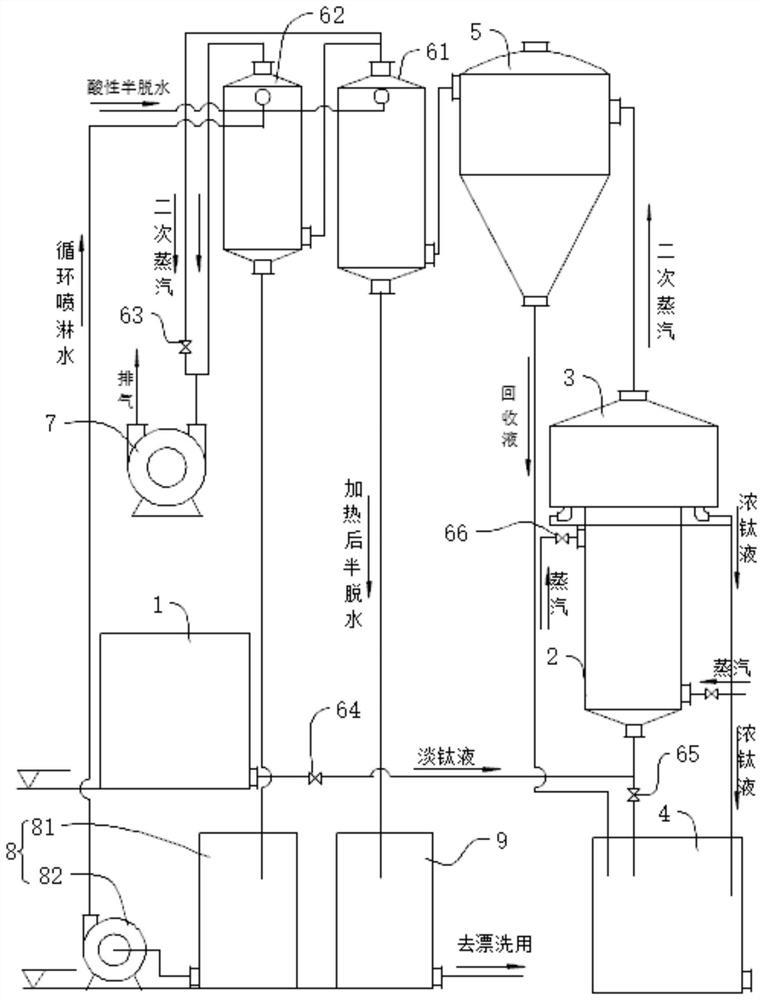

[0043] see figure 1 The evaporation module includes a light titanium tank 1, a heat exchanger 2, an evaporation chamber 3, a concentrated titanium tank 4, a cyclone separator 5, a primary steam condenser 61, a secondary steam condenser 62 and a vacuum pump 7. The outlet of the light titanium tank 1 is connected to the liquid inlet of the heat exchanger 2, and the liquid outlet 33 of the heat exchanger 2 is connected to the liquid inlet at the bottom of the evaporation chamber 3. The steam inlet of the heat exchanger 2 is connected with steam, and the steam outlet of the heat exchanger 2 is connected with the steam inlet of the evaporation chamber 3 . The liquid outlet 33 of the evaporation chamber 3 is connected with the concentrated titanium tank 4, and the steam outlet of the evaporation chamber 3 is connected with the steam inlet of the cyclone separator 5. The liquid outlet 33 of the cyclone separator 5 is connected with the concentrated titanium tank 4, the steam outlet ...

Embodiment 2

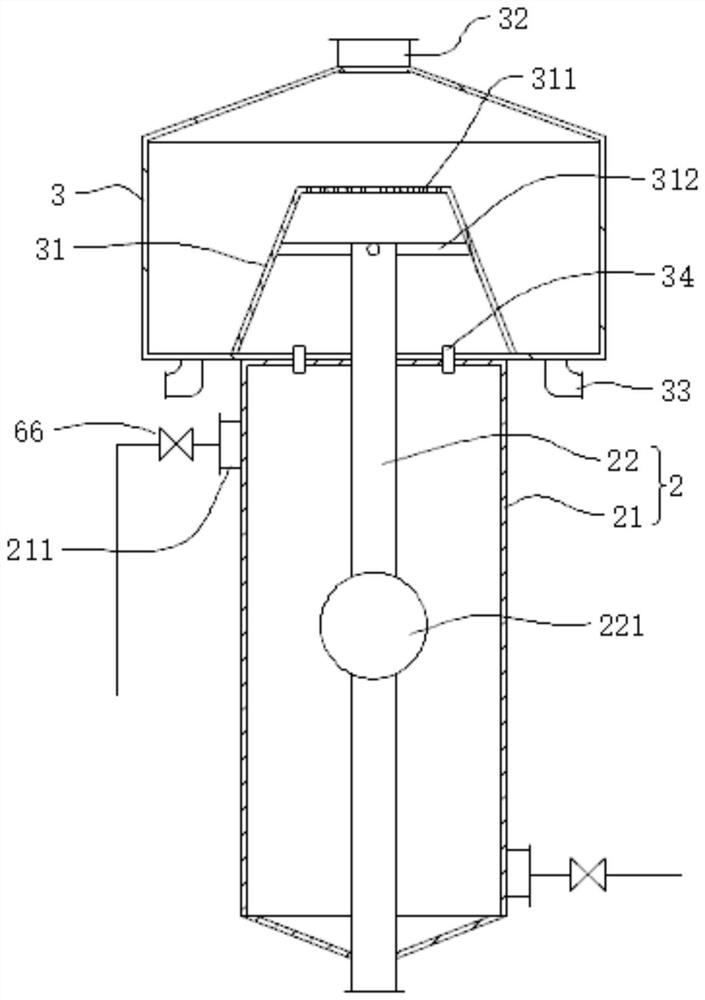

[0047] The difference between this embodiment and the first embodiment lies in the further improvement of the structures of the heat exchanger 2 and the evaporation chamber 3 , and the improvements of the heat exchanger 2 and the evaporation chamber 3 will be described in detail below.

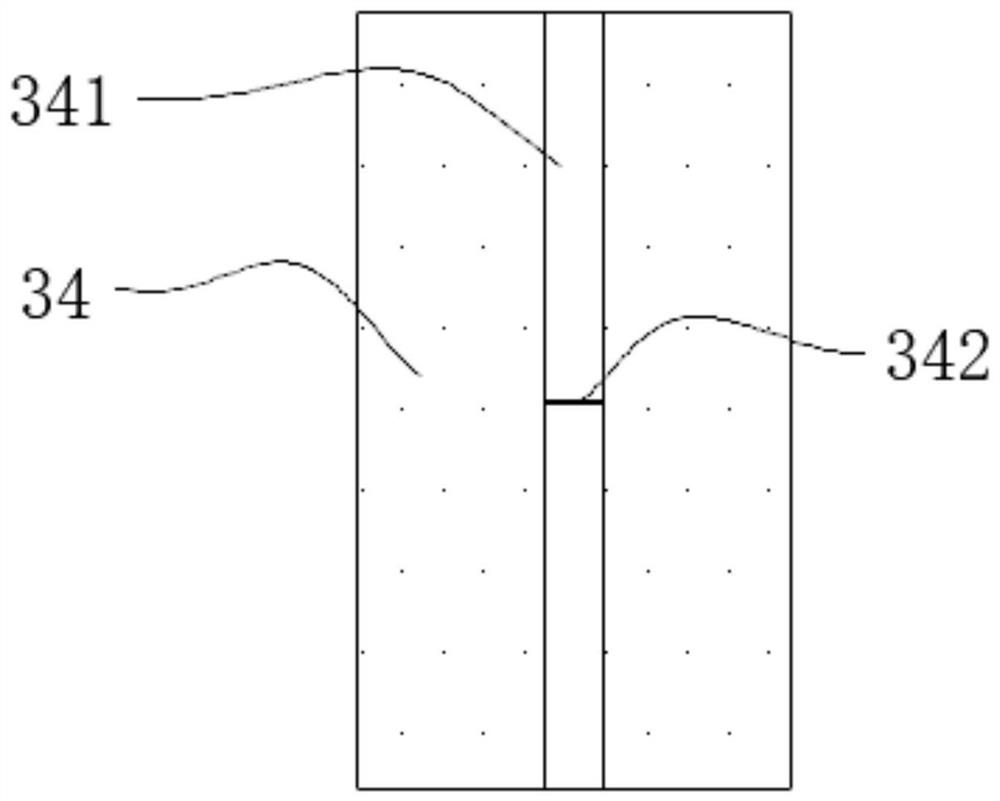

[0048] refer to figure 2 , The heat exchanger 2 includes a cylindrical shell 21 and a heat exchange tube 22. The cylindrical shell 21 is in the shape of a barrel, and its outer wall is coated with an insulating material, such as polyurethane, and the cylindrical shell 21 is vertically arranged. The shell 21 is provided with a first steam port 211, the first steam port 211 communicates with the inner wall of the shell 21, and there are two first steam ports 211, and the two first steam ports 211 are respectively set on the shell 21 At the upper and lower ends, when steam is connected to the two first steam ports 211 , the steam at both ends of the cylindrical shell 21 is opposed in the middle ...

Embodiment 3

[0053] The embodiment of the present application discloses a titanium dioxide concentration process, referring to Figure 5 , the titanium dioxide concentration process includes the following steps: a, heat exchange, the light titanium solution is passed into the heat exchanger 2 to be heated, and then passed into the evaporation chamber 3; b, separation, the secondary steam generated in the evaporation chamber 3 is introduced into Separation in the cyclone separator 5, so that the titanium liquid solute contained in the secondary steam is separated from the steam, and the titanium liquid solute is introduced into the thick titanium tank 4; c, condensation, the steam derived in the cyclone separator 5 is passed into steam condensation Condensate in the condenser, and guide the acid semi-dehydration into the steam condenser for heating.

[0054] The implementation principle of a titanium dioxide concentration system and process in the embodiment of the present application is as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com