A new process for preparing fully water-soluble titanyl sulfate powder

A titanium oxysulfate powder, titanium oxysulfate technology, applied in the direction of titanium and titanyl sulfate, titanium compounds, inorganic chemistry, etc., can solve the problems affecting product purity, high equipment maintenance cost, high energy consumption, etc., to simplify production Process flow, reducing anti-corrosion sealing requirements, reducing the effect of sulfuric acid usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

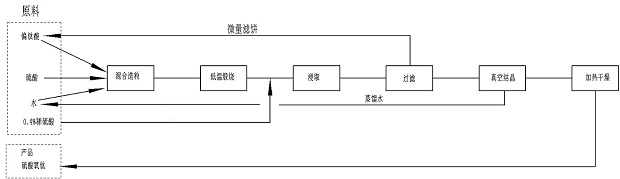

Image

Examples

Embodiment 1

[0024] A new process for preparing fully water-soluble titanium oxysulfate powder, comprising the following steps:

[0025] (1) Take 1000 g of industrial metatitanic acid solid, dry it at 120 °C for 2 hours, and sieve it with a 100-mesh stainless steel sieve after crushing;

[0026] (2) Mix and granulate the sieved metatitanic acid powder with 98% sulfuric acid and distilled water, and the material ratio of metatitanic acid, sulfuric acid and water is 1:0.5:1;

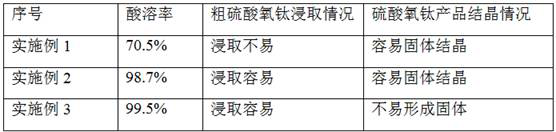

[0027] (3) Homogenize the material ball at 120 °C for 1 hour, then heat it up to 260 °C for 8 hours, and the conversion rate of this step is about 70.5%;

[0028] (4) Cool and pulverize the calcined material balls, and sieve them with a 100-mesh stainless steel sieve;

[0029] (5) Use 1 times the mass of 0.4% dilute sulfuric acid to dissolve the sieved powder, and continue leaching for 6 hours at a temperature of 50 °C and an ultrasonic frequency of 40 kHz;

[0030] (6) Filter the leached slurry, and the clear and tr...

Embodiment 2

[0034] A new process for preparing fully water-soluble titanium oxysulfate powder, comprising the following steps:

[0035] (1) Take 1000 g of industrial metatitanic acid solid, dry it at 120 °C for 2 hours, and sieve it with a 100-mesh stainless steel sieve after crushing;

[0036] (2) Mix and granulate the sieved metatitanic acid powder with 98% sulfuric acid and distilled water, and the material ratio of metatitanic acid, sulfuric acid and water is 1:1.25:0.2;

[0037] (3) The material balls were homogenized at 120 °C for 1 hour, and then heated to 260 °C and calcined for 8 hours. The conversion rate of this step was 98.7%;

[0038] (4) Cool and pulverize the calcined material balls, and sieve them with a 100-mesh stainless steel sieve;

[0039] (5) Use 0.4% dilute sulfuric acid with twice the mass of the solid material to dissolve the sieved powder, and continue leaching for 6 hours at a temperature of 50 °C and an ultrasonic frequency of 40 kHz;

[0040] (6) Filter the ...

Embodiment 3

[0045] A new process for preparing fully water-soluble titanium oxysulfate powder, comprising the following steps:

[0046] (1) Take 1000 g of industrial metatitanic acid solid, dry it at 120 °C for 2 hours, and sieve it with a 100-mesh stainless steel sieve after crushing;

[0047] (2) Mix and granulate the sieved metatitanic acid powder with 98% sulfuric acid and distilled water, and the material ratio of metatitanic acid, sulfuric acid and water is 1:3:0.2;

[0048] (3) The material balls were homogenized at 120 °C for 1 hour, and then heated to 260 °C and calcined for 8 hours. The conversion rate of this step was 99.5%;

[0049] (4) Cool and pulverize the calcined material balls, and sieve them with a 100-mesh stainless steel sieve;

[0050] (5) Use 0.4% dilute sulfuric acid with twice the mass of the solid material to dissolve the sieved powder, and continue leaching for 6 hours at a temperature of 50 °C and an ultrasonic frequency of 40 kHz;

[0051] (6) Filter the lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com