Three-stage negative pressure evaporation crystallization treatment process and device for titanium dioxide waste sulfuric acid

A negative pressure evaporation and crystallization technology, applied in the fields of titanium and titanyl sulfate, filtration treatment, heating water/sewage treatment, etc., can solve the problems of easy clogging of the evaporator, low evaporation temperature, waste of resources, etc. Possibility of crystallization and clogging, low evaporation temperature, effect to ensure stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

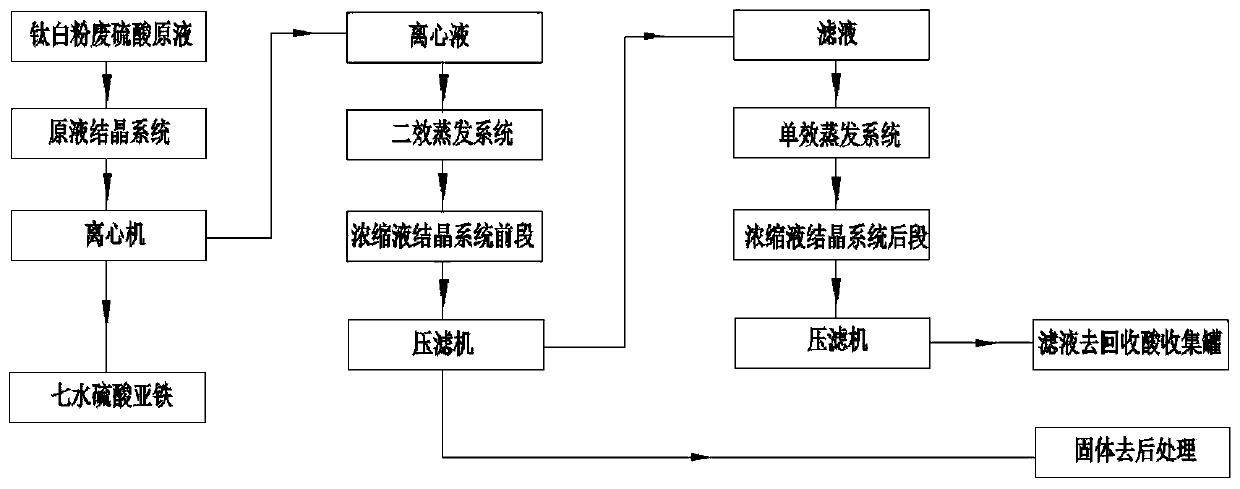

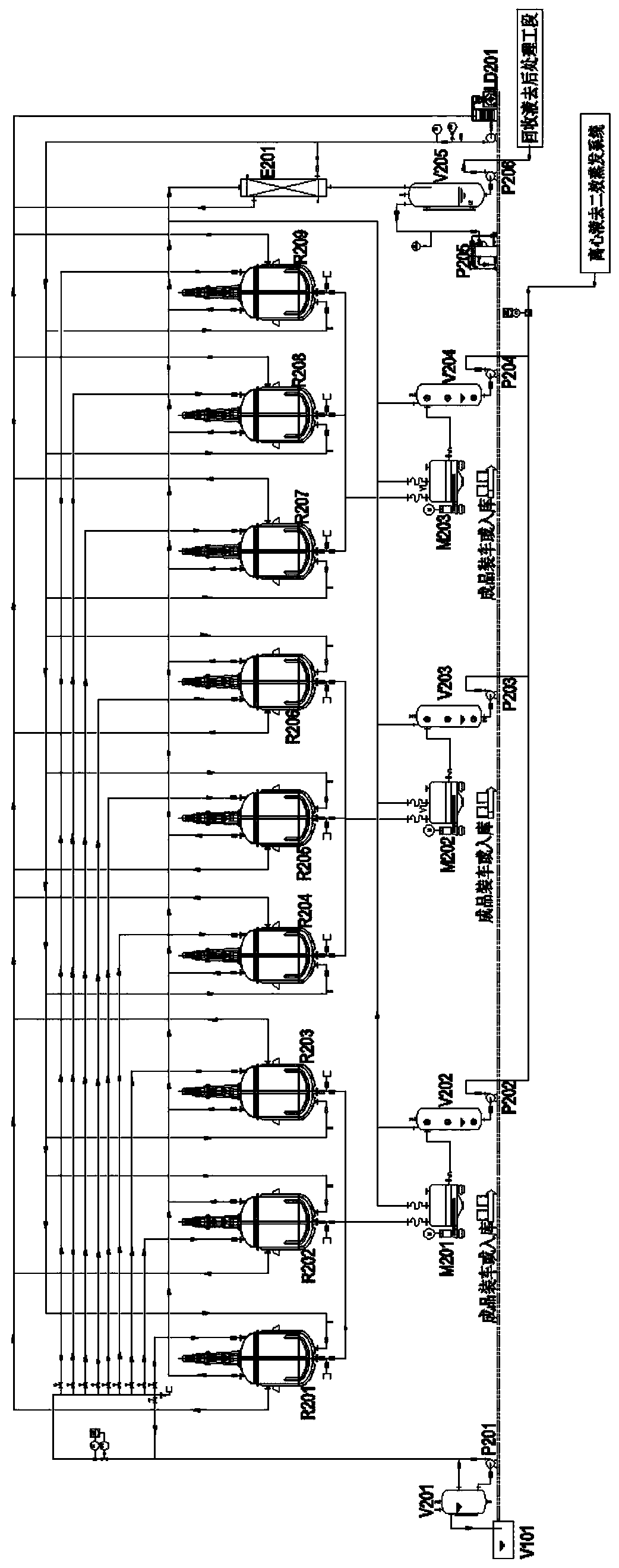

[0042] Such as figure 1 As shown, the present invention is a three-stage negative pressure evaporation crystallization process flow for titanium dioxide waste sulfuric acid, comprising the following steps:

[0043] S1: Negative pressure freezing and crystallization, put the titanium dioxide waste sulfuric acid stock solution into the stock solution crystallization tank in the stock solution crystallization system, freeze and crystallize it under negative pressure for a period of time, and centrifuge the titanium dioxide waste sulfuric acid crystal slurry in each stock solution crystallization tank to obtain Ferrous sulfate heptahydrate solid and centrifugate;

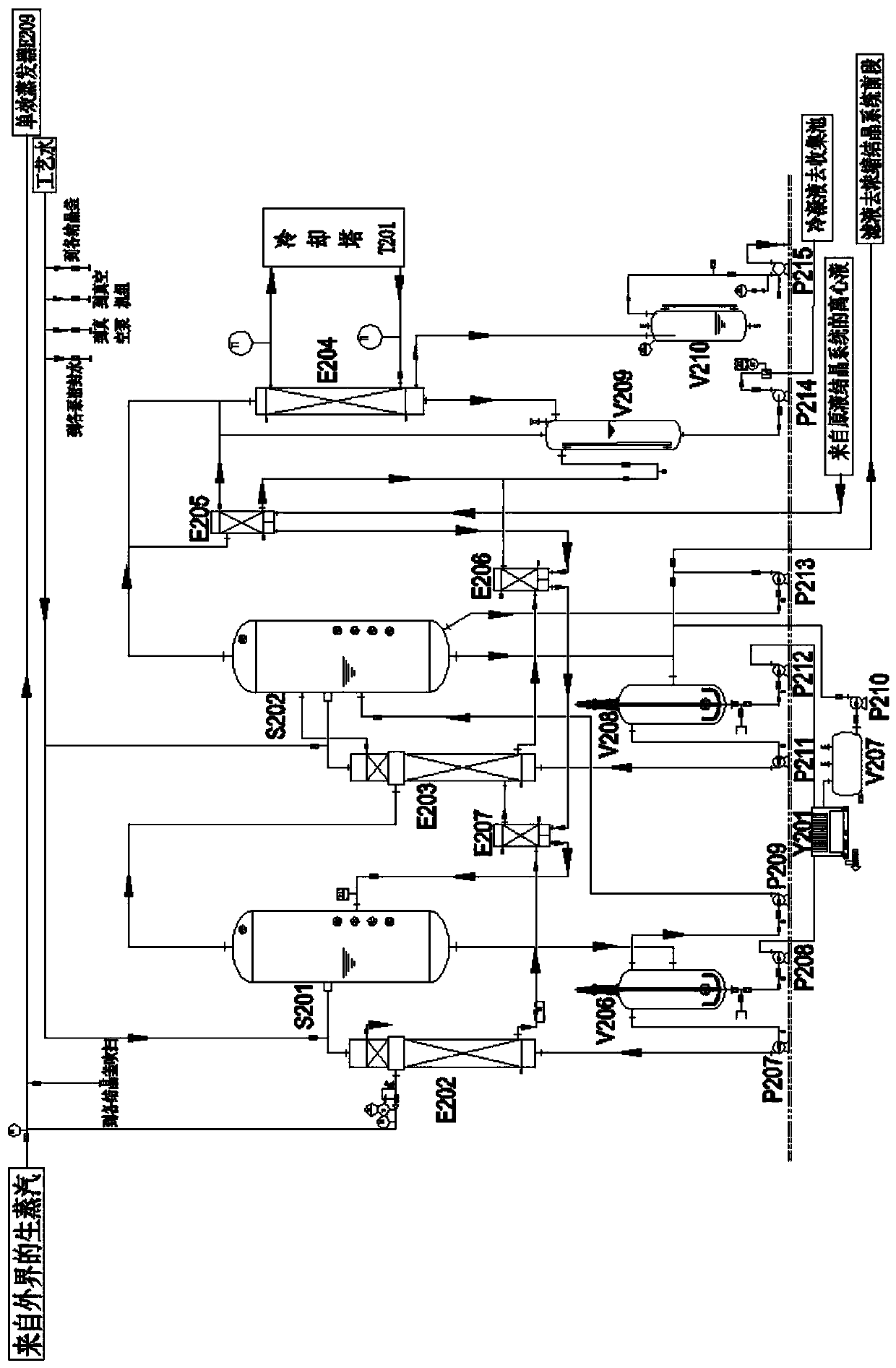

[0044]S2: Two-effect evaporation and concentration. The centrifugate in step S1 is pumped into the first-effect evaporation unit of the second-effect evaporation system, and the steam generated from the outside provides saturated steam to the first-effect evaporation unit, and the centrifugate undergoes primary evaporat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com