The preparation method of trivalent titanium solution

A technology of trivalent titanium and solution, applied in chemical instruments and methods, titanium compounds, titanium and titanyl sulfate, etc., can solve the problems of pollution, occupation of titanium gypsum, etc., to reduce production costs, reduce titanium gypsum, The effect of reducing the amount of lime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Prepare trivalent titanium solution A as follows:

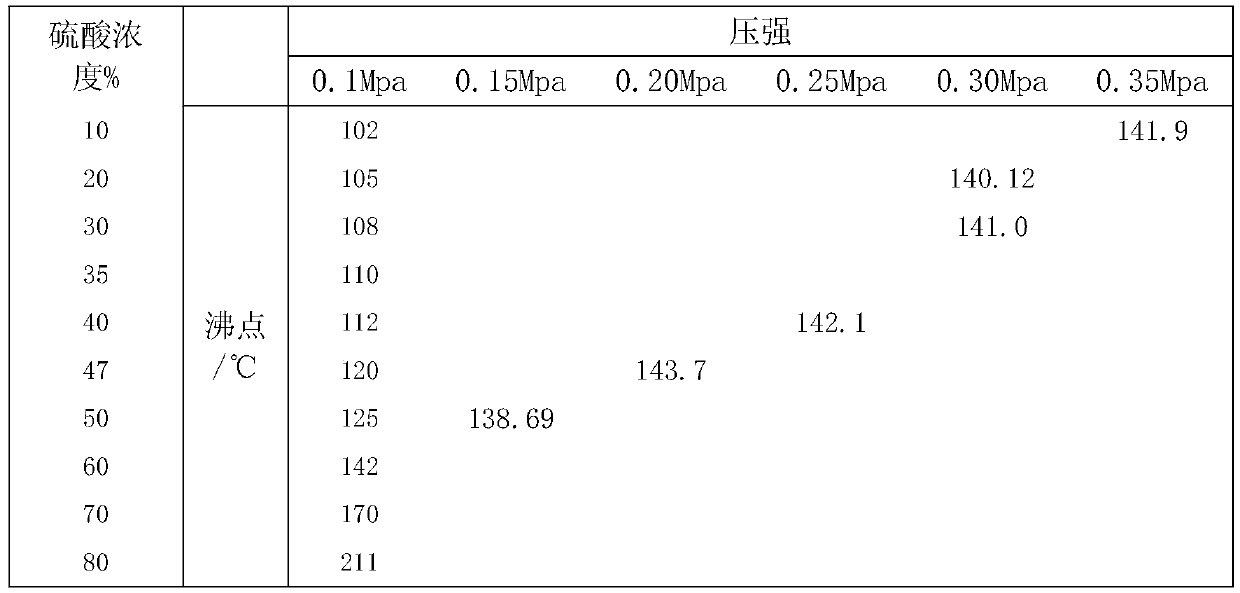

[0034] (1) Take a wash metatitanic acid slurry (TiO 2 =300g / l) and 98 acids are injected into the pressure vessel and mixed uniformly to obtain a mixture, and the liquid phase of the mixture is a sulfuric acid solution; the one-washed metatitanic acid slurry (by TiO 2 meter) and 98 acid (according to H 2 SO 4 The ratio of mass) is 1:1.8;

[0035] (2) record sulfuric acid solution mass concentration and be 9.9%;

[0036] (3) Then close the pressure vessel, and pressurize to control the internal pressure of the pressure vessel at 0.35Mpa;

[0037] (4) Heating the internal reaction system of the pressure vessel to boiling, and maintaining boiling for 30 minutes to obtain an acid-soluble solution;

[0038] (5) Stop heating, release the pressure, cool down to 70°C, add metered water to the above acid-soluble solution to adjust the concentration to TiO 2 =90g / l, then add aluminum powder (the mass ratio of aluminum powder...

Embodiment 2

[0041] Prepare trivalent titanium solution B as follows:

[0042] (1) Take a wash metatitanic acid slurry (TiO 2 =300g / l) and 98 acids are injected into the pressure vessel and mixed uniformly to obtain a mixture, and the liquid phase of the mixture is a sulfuric acid solution; the one-washed metatitanic acid slurry (by TiO 2 meter) and 98 acid (according to H 2 SO 4 The mass ratio of meter) is 1:2.4;

[0043] (2) record sulfuric acid solution mass concentration and be 12.3%;

[0044] (3) Then close the pressure vessel, and pressurize to control the internal pressure of the pressure vessel at 0.32Mpa;

[0045] (4) Heating the internal reaction system of the pressure vessel to boiling, and maintaining boiling for 40 minutes to obtain an acid-soluble solution;

[0046] (5) Stop heating, release the pressure, cool down to 70°C, add metered water to the above acid-soluble solution to adjust the concentration to TiO 2 =90g / l, then add aluminum powder (the mass ratio of alumin...

Embodiment 3

[0049] Trivalent titanium solution C was prepared as follows:

[0050] (1) Take a wash metatitanic acid slurry (TiO 2 =300g / l) and the concentrated sulfuric acid injection pressure vessel that mass concentration is 93% mixes uniformly, obtains mixture, and the liquid phase of described mixture is sulfuric acid solution; 2 In terms of) and concentrated sulfuric acid (according to H 2 SO 4 The ratio of mass) is 1:4.8;

[0051] (2) record sulfuric acid solution mass concentration and be 47.2%;

[0052] (3) Then close the pressure vessel, and pressurize to control the internal pressure of the pressure vessel at 0.20Mpa;

[0053] (4) Heating the internal reaction system of the pressure vessel to boiling, and maintaining boiling for 40 minutes to obtain an acid-soluble solution;

[0054] (5) Stop heating, release the pressure, cool down to 70°C, add metered water to the above acid-soluble solution to adjust the concentration to TiO 2 =90g / l, then add aluminum powder (the mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com