Reactor for producing titanium sulphate compound by process intensified continuous acidolysis reaction

A technology of reactors and titanium compounds, applied in the field of reactors, can solve problems such as excessive stirring, difficulty in controlling acid gas release, unevenness, etc., and achieve the effect of reducing reaction dead angle, reducing hardening rate, and reducing gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

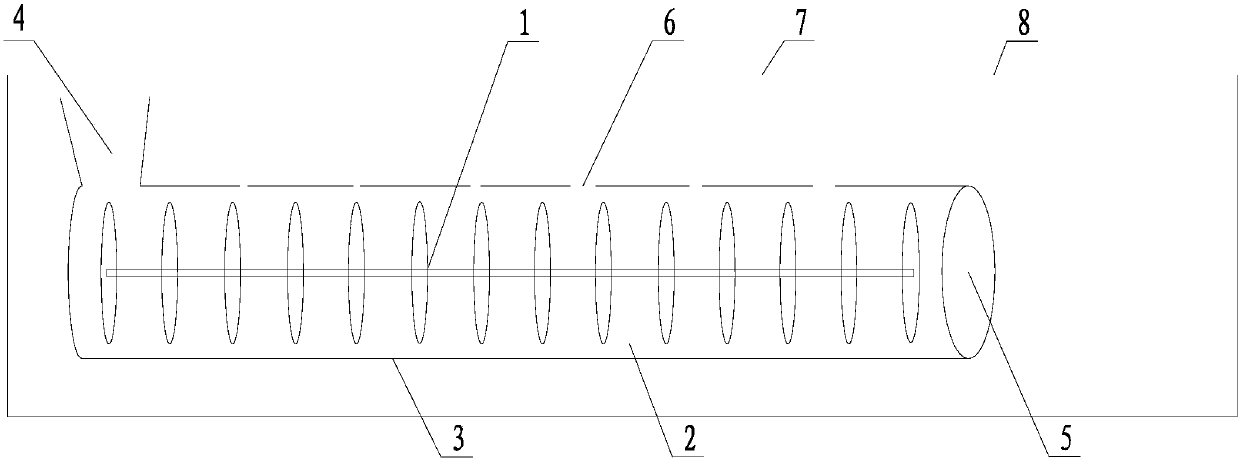

[0019] like figure 1 As shown, the application provides a novel continuous acidolysis reactor, the reactant, such as the mixture of sulfuric acid and titanium concentrate, enters the continuous acidolysis reactor from the feed port, and under the agitation of the spiral stirrer, the reactant is in the Acid hydrolysis reaction occurs in the reactor, and the reaction product is discharged out of the reactor at a certain speed. Holes can be set at the top of the continuous acidolysis reactor, and part of the acid gas can be discharged from these holes. The discharged acid gas can be introduced into the acid gas treatment system to prevent the acid gas from leaking to the surrounding area.

[0020] The reaction time of the reactants in the continuous acidolysis reactor is determined by the length of the helical agitator and the continuous acidolysis reactor. The calculation shows that under the condition that the reaction time is set to 1 hour, a continuous acidolysis reactor wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com