Method for efficiently purifying titanous sulfate liquid

A titanium sulfate, high-efficiency technology, applied in the field of separation and purification, can solve the problems of difficult to control the quality of titanium liquid, large volume of plate and frame filtration equipment, reducing the concentration of titanium liquid, etc., to achieve the effect of easy control, small volume, and improved environmental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

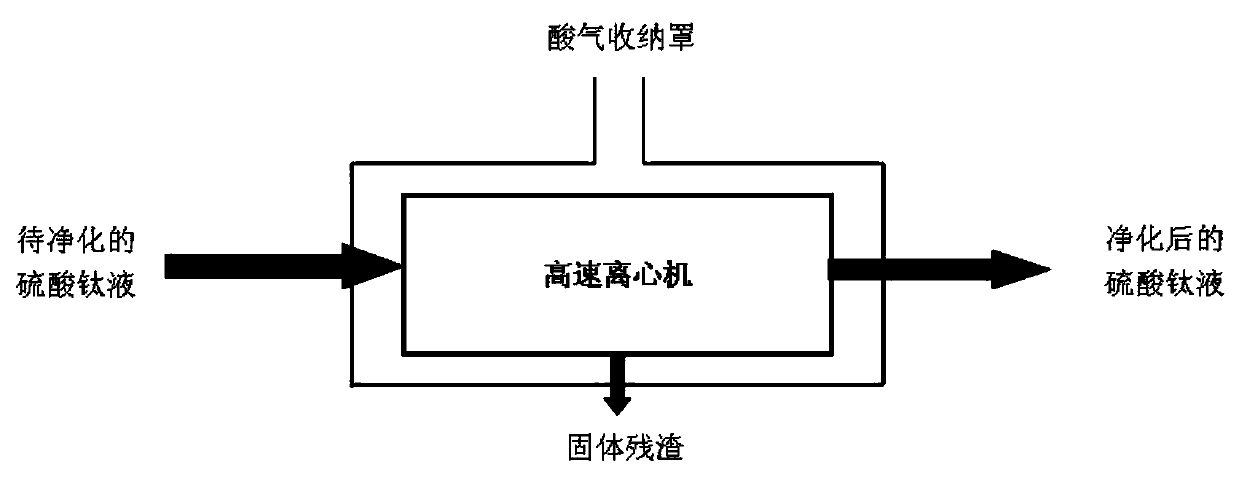

Image

Examples

Embodiment 1

[0028] Put 180ml of the concentrated titanium sulfate solution (the solid content of the residue is 28mg / L, the mass content of titanium dioxide is about 195g / L) into the high-speed centrifuge, and centrifuge for 10 minutes at a speed of 9000 rpm. After centrifugation, the solid residue It is deposited at the bottom of the centrifugal equipment to realize the separation of solid residue and titanium liquid. After centrifugal separation, deeply purified titanium sulfate liquid is obtained. The solid content of titanium liquid residue is reduced to 14mg / L, and the mass content of titanium dioxide remains unchanged (about 195g / L ).

Embodiment 2

[0030] The supernatant 180ml (residue solid content is 601mg / L, titania weight content about 120g / L) of the titanium sulfate solution after sedimentation is input high-speed centrifuge, under the condition of 9000 rev / mins, centrifugal 10 minutes, After centrifugation, the solid residue is deposited on the bottom of the centrifuge equipment to realize the separation of the solid residue and the titanium liquid. After centrifugation, a deeply purified titanium sulfate liquid is obtained. The solid content of the residue is reduced to 10mg / L, and the mass content of titanium dioxide remains unchanged (about 120g / L).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com