Composite ternary material as well as preparation method and application thereof

A ternary material and mixture technology, applied in chemical instruments and methods, alumina/hydroxide preparation, nickel compounds, etc., can solve the problem of separate precipitation of doping elements, uneven doping of nickel-cobalt-manganese ternary materials, influence The electrochemical properties of materials can be improved to improve cycle stability, improve anti-overcharge and thermal stability, and prevent direct contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

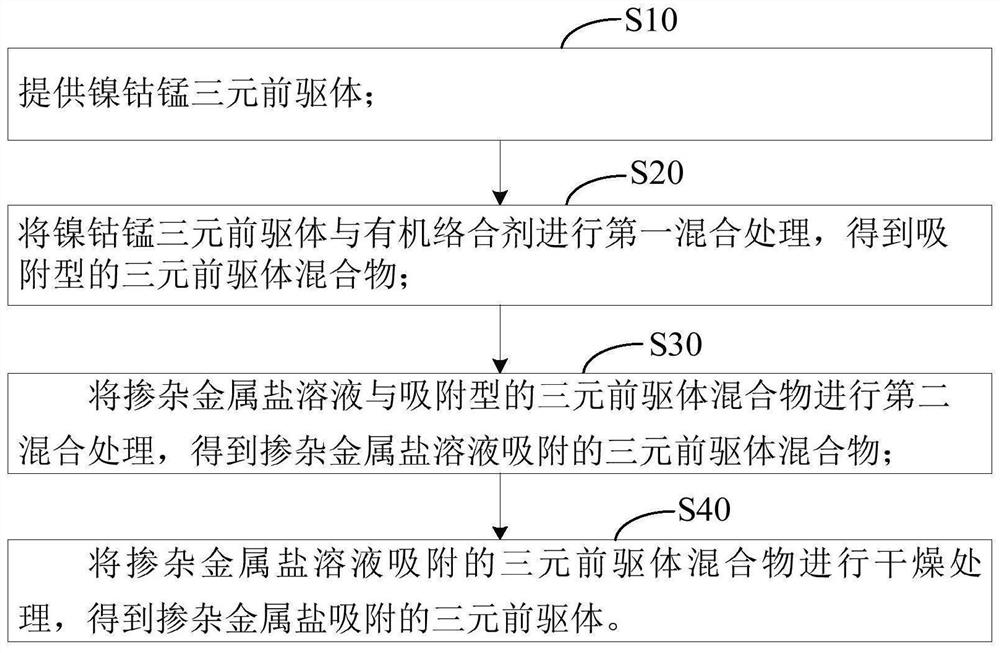

[0039] The second aspect of the embodiment of the present application provides a method for preparing a composite ternary precursor, including:

[0040] S10: Provide nickel-cobalt-manganese ternary precursor;

[0041] S20: performing a first mixing treatment on the nickel-cobalt-manganese ternary precursor and the organic complexing agent to obtain an adsorption-type ternary precursor mixture;

[0042] S30: performing a second mixing treatment on the doped metal salt solution and the adsorption-type ternary precursor mixture to obtain a ternary precursor mixture adsorbed by the doped metal salt solution;

[0043] S40: drying the ternary precursor mixture adsorbed by the doped metal salt solution to obtain a ternary precursor adsorbed by the doped metal salt.

[0044] In the preparation method of the composite ternary precursor provided in the embodiment of the present application, the nickel-cobalt-manganese ternary precursor is first mixed with an organic complexing agent to...

Embodiment 1

[0065] This embodiment provides a method for preparing a composite ternary precursor and ternary material, including the following steps:

[0066] One, a kind of preparation method of composite ternary precursor, comprises the following steps:

[0067] S10: The preparation method of the nickel-cobalt-manganese ternary precursor includes: dissolving nickel salt, cobalt salt, and manganese salt in water respectively, and mixing them according to the molar ratio of 6:2:2 to obtain a nickel-cobalt-manganese mixed solution; Next, the nickel-cobalt-manganese mixed solution was co-precipitated with sodium hydroxide and ammonia water to obtain a nickel-cobalt-manganese ternary precursor.

[0068] S20: Mix the nickel-cobalt-manganese ternary precursor with 8-hydroxyquinoline, and keep stirring for 3 hours to generate an adsorption-type ternary precursor mixture.

[0069] S30: TiSO 4 The solution is gradually added to the adsorption-type ternary precursor mixture under stirring, ultra...

Embodiment 2

[0075] This embodiment provides a method for preparing a composite ternary precursor and ternary material, including the following steps:

[0076] One, a kind of preparation method of composite ternary precursor, comprises the following steps:

[0077] S10: The preparation method of the nickel-cobalt-manganese ternary precursor includes: dissolving nickel salt, cobalt salt, and manganese salt in water respectively, and mixing them according to the molar ratio of 6:2:2 to obtain a nickel-cobalt-manganese mixed solution; Next, the nickel-cobalt-manganese mixed solution was co-precipitated with sodium hydroxide and ammonia water to obtain a nickel-cobalt-manganese ternary precursor.

[0078] S20: Mix the nickel-cobalt-manganese ternary precursor with 8-hydroxyquinoline, and keep stirring for 3 hours to generate an adsorption-type ternary precursor mixture.

[0079] S30: MgSO 4 The solution is gradually added to the adsorption-type ternary precursor mixture under stirring, ultra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com