Method for comprehensively utilizing waste acid and waste alkali for producing high-purity magnesium sulfate

A technology of comprehensive utilization and waste sulfuric acid, applied in magnesium sulfate and other directions, to achieve the effects of less equipment investment, good application and promotion prospects, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

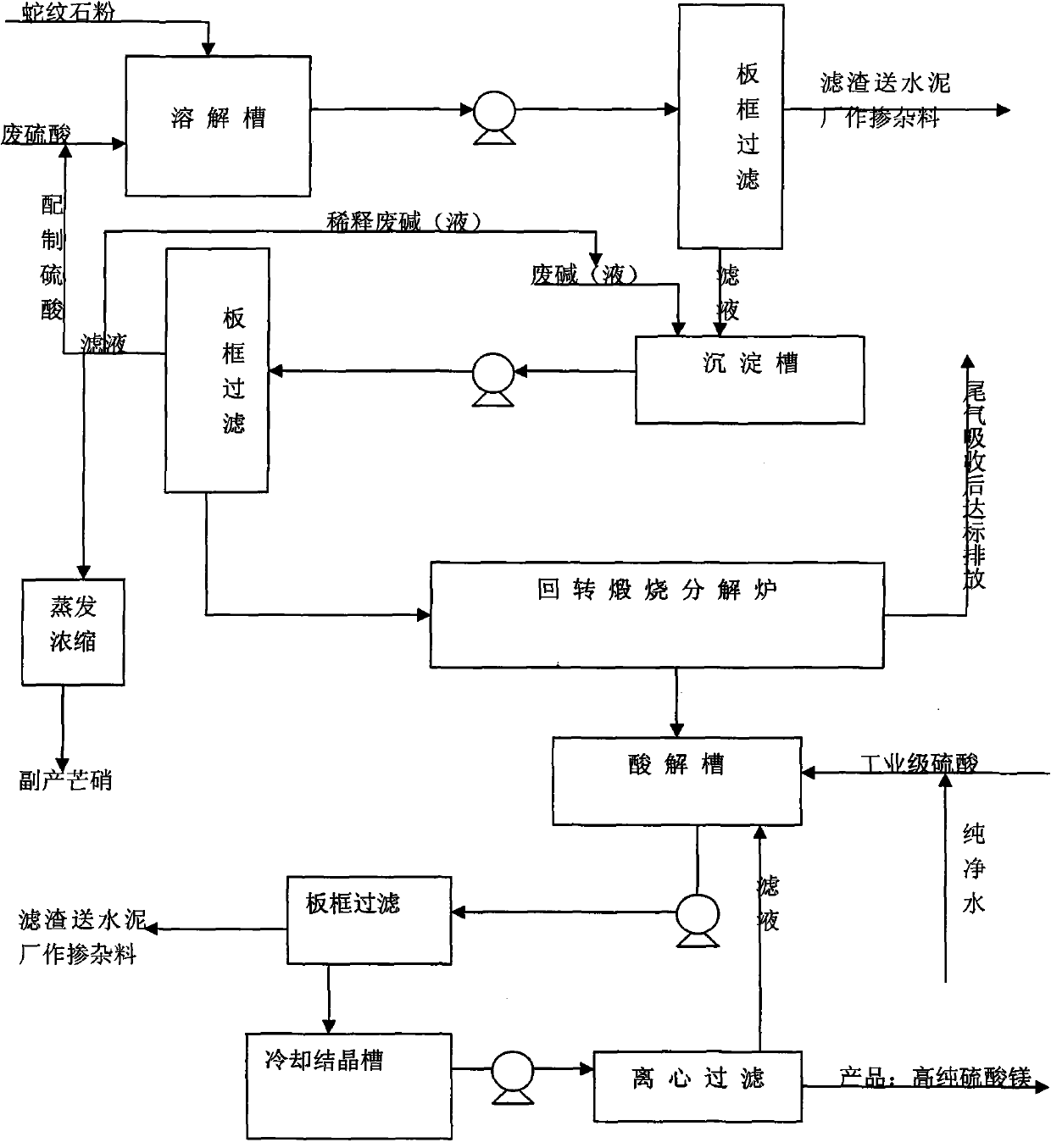

Image

Examples

Embodiment 1

[0012] Adjust the concentration of waste sulfuric acid to 20% and add it into the mixed slurry of serpentine powder and water, stir and react for a period of time, and pump it into a plate and frame filter press for filtration. After the filter residue is dried, it is sent to the cement plant to be used as a doping material. The filtrate is neutralized with 8%-15% waste caustic soda solution to pH=7.5-8, and then the suspension is pumped into a plate and frame filter press for filtration. A part of the filtrate is used to prepare the mixed slurry of serpentine powder and water, a part is used to prepare caustic soda or sodium carbonate solution, and the rest is sent to the evaporator to be evaporated and concentrated for the by-product sodium sulfate. The filter residue is sent to the rotary calciner, and the residual organic matter in it is completely decomposed at a certain temperature. The decomposed material is cooled and sent to the acidolysis tank, and a certain amount ...

Embodiment 2

[0014] The waste sulfuric acid is adjusted to 20% and added to the mixed slurry of serpentine powder and water, stirred and reacted for a period of time, and then pumped into a plate and frame filter press for filtration. After the filter residue is dried, it is sent to the cement plant to be used as a doping material. The filtrate is neutralized to pH=7.5-8 with 10%-20% waste soda ash solution, and then the suspension is pumped into a plate and frame filter press for filtration. A part of the filtrate is used to prepare the mixed slurry of serpentine powder and water, a part is used to prepare caustic soda or sodium carbonate solution, and the rest is sent to the evaporator to be evaporated and concentrated for the by-product sodium sulfate. The filter residue is sent to the rotary calciner, and the residual organic matter in it is completely decomposed at a certain temperature. The decomposed material is cooled and sent to the acidolysis tank, and a certain amount of pure w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com