Hydraulic pressure grabhook

A hydraulic and external cylinder technology, applied in the field of manipulators, can solve the problems of unreliability, small clamping force, small application range, etc., and achieve the effect of flexible expansion and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

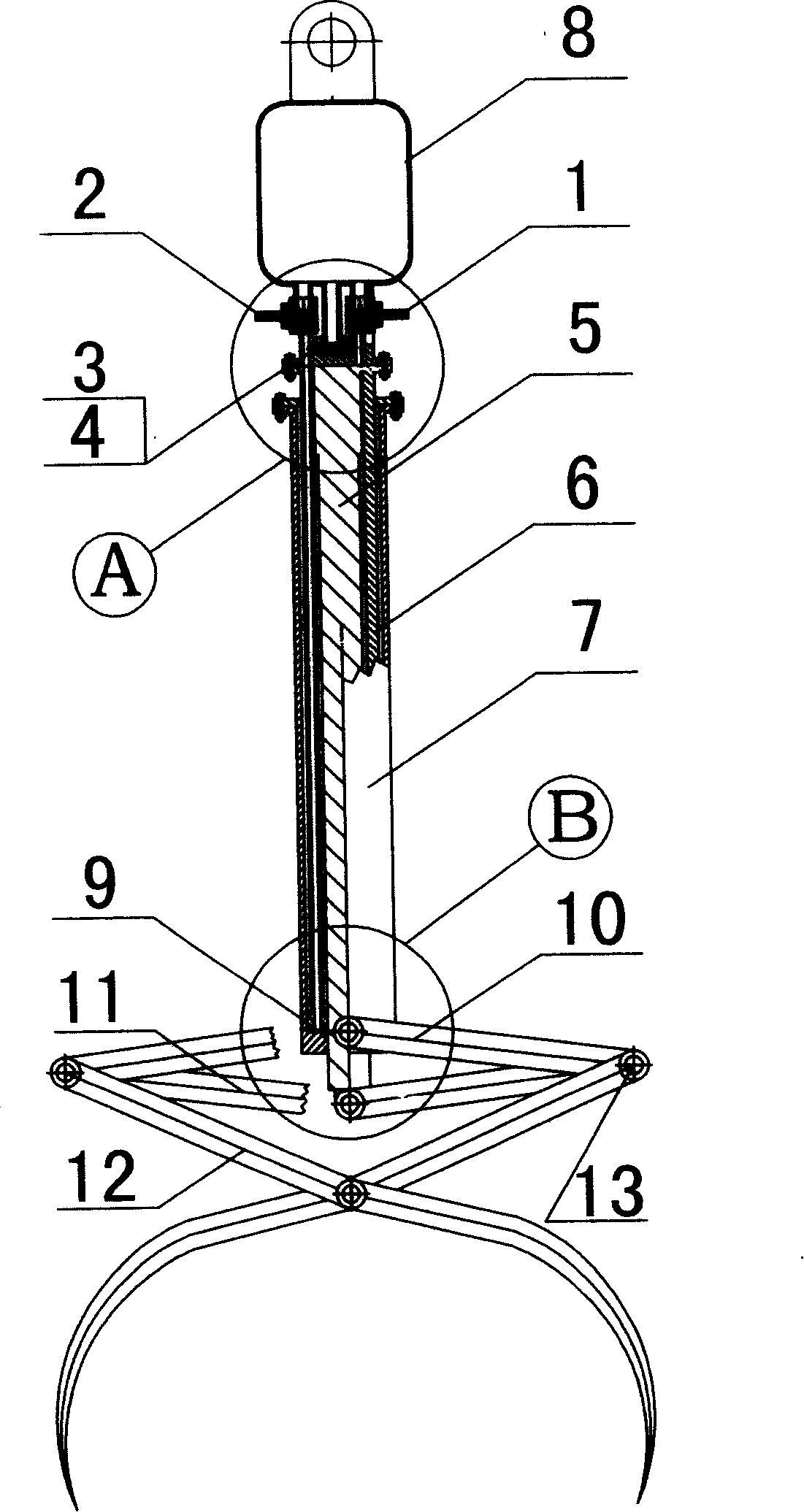

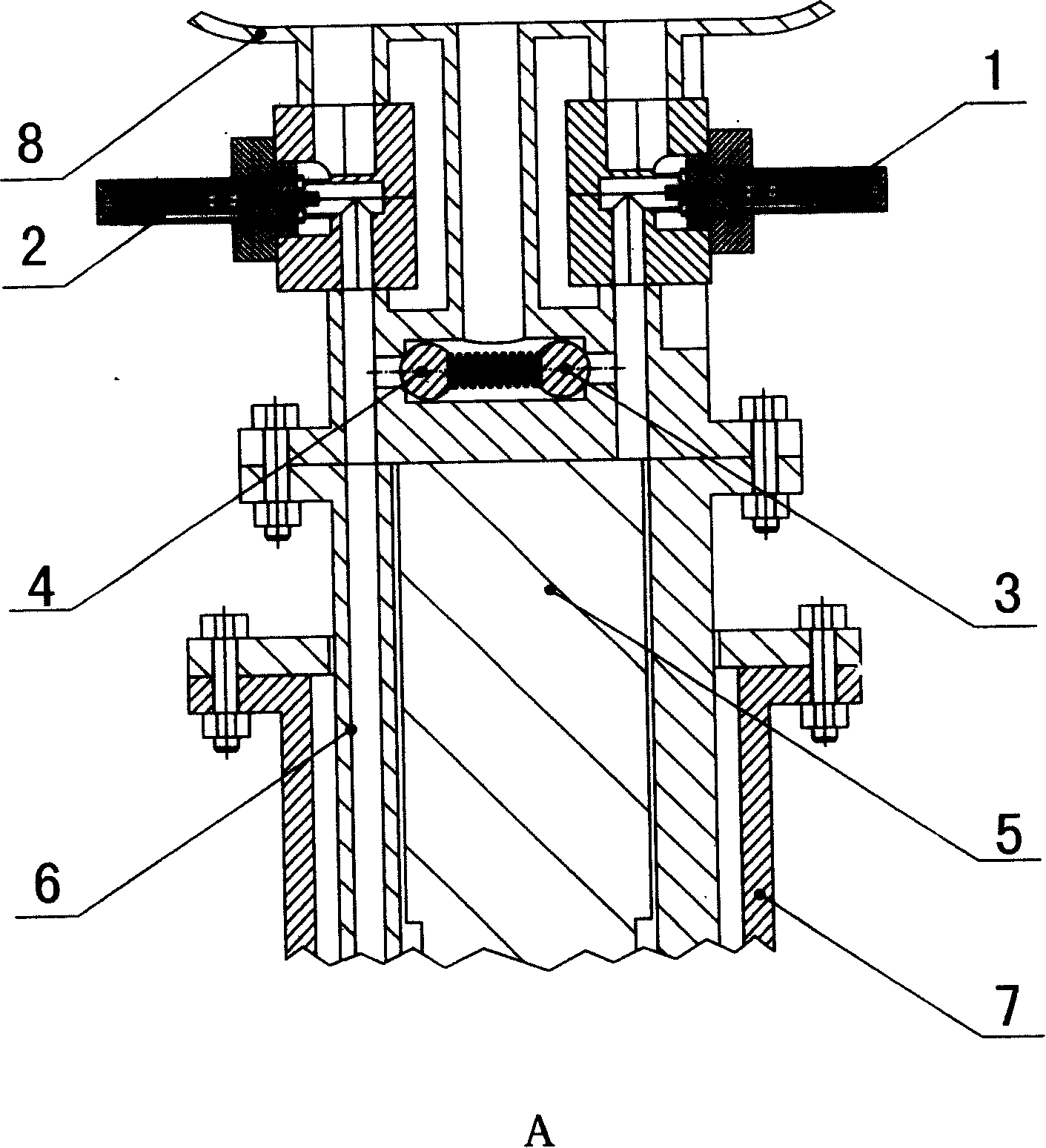

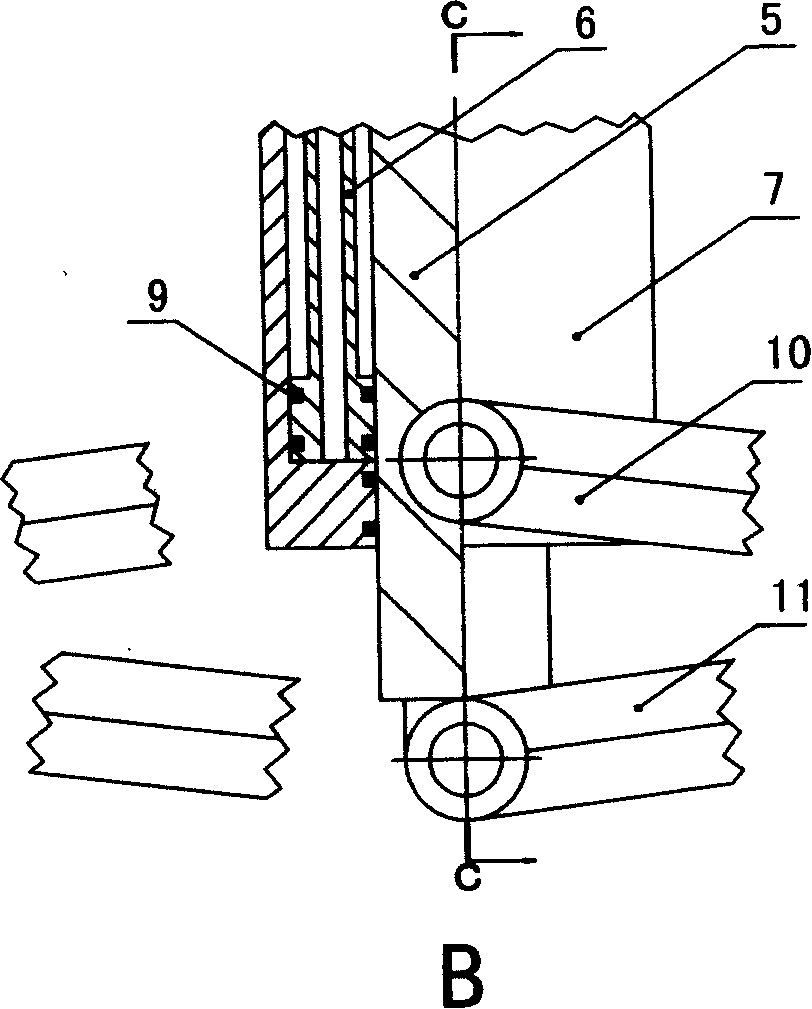

[0006] Depend on figure 1 , figure 2 , image 3 , Figure 4 , Solenoid valves (1), (2) select ZCB high-pressure solenoid valves, such as ZCBDN10, hydraulic oil tank (8) is made of A3 steel, the upper part is formed with mounting lug holes connected with supporting machinery, piston (5), inner cylinder body (6), the outer cylinder body (7) is made of 45# steel, the upper connecting rod (10), the lower connecting rod (11), and the hook (12) are made of 45# steel, and the connecting rod shaft pin (13) Made with bearing steel, sealing ring (9) selects O type rubber sealing ring for use. During implementation, solenoid valves (1), (2) are installed with a photoelectric remote controller to control their operation or cable control operation. One-way check valves (3), (4) select Φ10mm steel ball one-way check valves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com