Method for treating titanium dioxide wastewater

A technology for titanium dioxide wastewater and white gypsum, which is applied in multi-stage water treatment, solid waste management, sustainable waste treatment, etc., can solve the problems of low wastewater treatment efficiency, difficult to measure proportion, and unsuitable for large-scale industrial production, etc. Achieve the effect of reducing the cost of calcination and drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

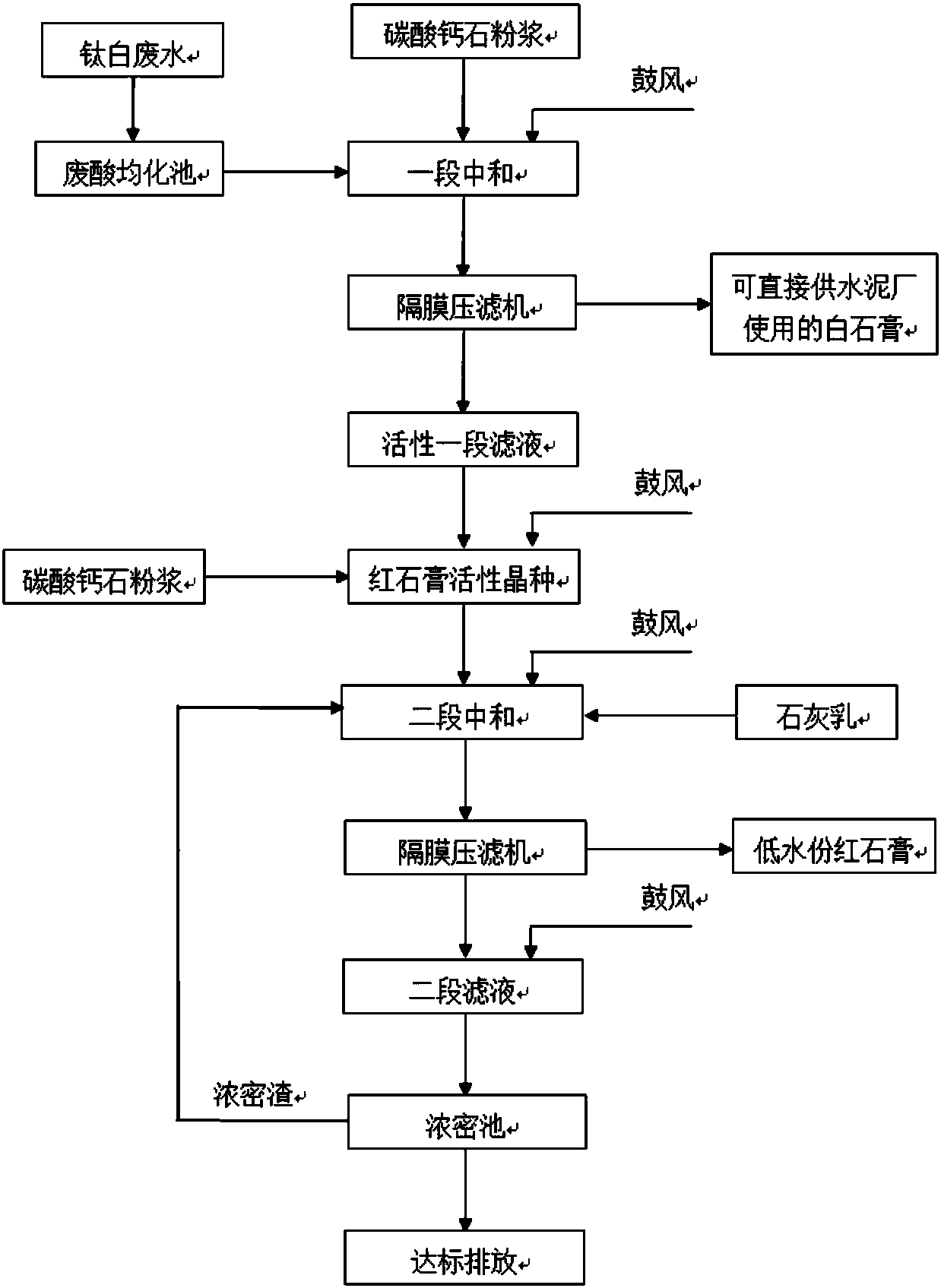

[0030] A method for treating titanium dioxide wastewater, comprising the steps of:

[0031] (1) Preparation of white gypsum: pump the homogenized titanium dioxide wastewater into the reaction tank, wherein the main components and concentrations of the homogenized titanium dioxide wastewater are H 2 SO 4 =70.62g / l; TiOSO 4 = 2.34g / l; FeSO 4 =40.10g / l; Stability > 200, at the same time, pump the calcium carbonate stone powder slurry into the reaction tank, under the condition of blasting, mechanically stir, when the pH of the material is detected to be 1.52, stop stirring, and pass through the membrane filter press Separation of solid and liquid to obtain the filtrate of the first stage of activity and white gypsum. The white gypsum is directly used by the cement plant. 3 =43.83%; the test index of filtrate of the first stage of activity: H 2 SO4=18.13g / l, TiOSO 4 =2.15g / l, FeSO 4 =36.84g / l, stability>200;

[0032] (2) Red gypsum active seed crystal preparation: pump the ...

Embodiment 2

[0036] A method for treating titanium dioxide wastewater, comprising the steps of:

[0037] (1) Preparation of white gypsum: pump the homogenized titanium dioxide wastewater into the reaction tank, wherein the main components and concentrations of the homogenized titanium dioxide wastewater are H 2 SO 4 = 68.10 g / l; TiOSO 4 = 3.04g / l; FeSO 4 =38.91g / l; Stability > 200, at the same time, pump the calcium carbonate stone powder slurry into the reaction tank, under the condition of blasting, mechanically stir, when the pH in the material is detected to be 1.62, stop stirring, and pass through the membrane filter press Separation of solid and liquid to obtain the filtrate of the first stage of activity and white gypsum, the white gypsum is directly used by the cement plant, the water content of the white gypsum = 24.86%, SO 3 =44.53%; the test index of filtrate of the first stage of activity: H 2 SO 4 = 17.65g / l, TiOSO 4 = 2.87g / l; FeSO 4 =36.74g / l, Stability>200.

[0038]...

Embodiment 3

[0042] A method for treating titanium dioxide wastewater, comprising the steps of:

[0043] (1) Preparation of white gypsum: pump the homogenized titanium dioxide wastewater into the reaction tank, wherein the main components and concentrations of the homogenized titanium dioxide wastewater are H 2 SO 4 = 65.57g / l; TiOSO 4 =2.71g / l; FeSO 4 =35.26g / l; Stability>200, at the same time, pump the calcium carbonate stone powder slurry into the reaction tank, under the condition of blast, mechanically stir, when the pH=1.62 in the detection material, stop stirring, pass through the membrane filter press Separation of solid and liquid to obtain the filtrate of the first stage of activity and white gypsum, the white gypsum is directly used by the cement plant, the water content of the white gypsum = 25.20%, SO 3 =44.72%; The test index of filtrate of the first stage of activity: H 2 SO 4 = 16.13 g / l, TiOSO 4 =2.56g / l, FeSO 4 =33.26g / l, Stability>200.

[0044] (2) Red gypsum act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com