Predecomposition kiln internal circulating flue gas desulfurization technology

A technology of precalcining kiln and internal circulation, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., and can solve problems such as complex management, difficult treatment of wet desulfurized gypsum, and large investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

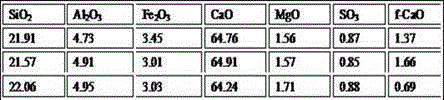

[0016] A 5000t / d cement plant in Wanzhou, Chongqing uses quicklime for desulfurization, and its clinker composition is:

[0017]

[0018] The online detection of the tail chimney shows that the average smoke emission is 900,000 m3 3 / h (temperature about 100°C), per ton of quicklime, can reduce SO 2 The amount is 70~80mg / m 3 . The flue gas discharged from the kiln tail is discharged from the C1 outlet through the vertical mill. Due to air leakage, the oxygen content in the flue gas will increase from about 2% to 10%, or even higher. Equivalent to C1 outlet desulfurization, each ton of quicklime can reduce SO 2 The amount is 120~140mg / m 3 .

Description of drawings

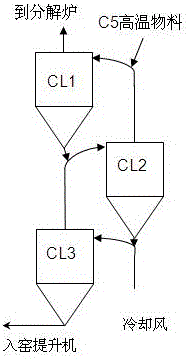

[0019] picture 1 is the engineering process of the present invention picture ;

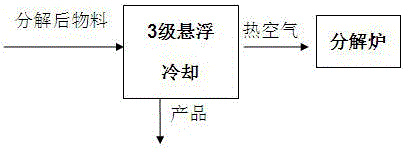

[0020] picture 2 is the process picture .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com