Method for desalting calcium magnesium slime by two-step process

A calcium-magnesium mud and desalination technology, applied in chemical instruments and methods, calcium/strontium/barium sulfate, sludge treatment, etc., can solve problems such as reducing the area of rock salt exposure, the risk of brine mining production, and reducing the concentration of brine produced. Achieve the effect of less investment in equipment, short construction period and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

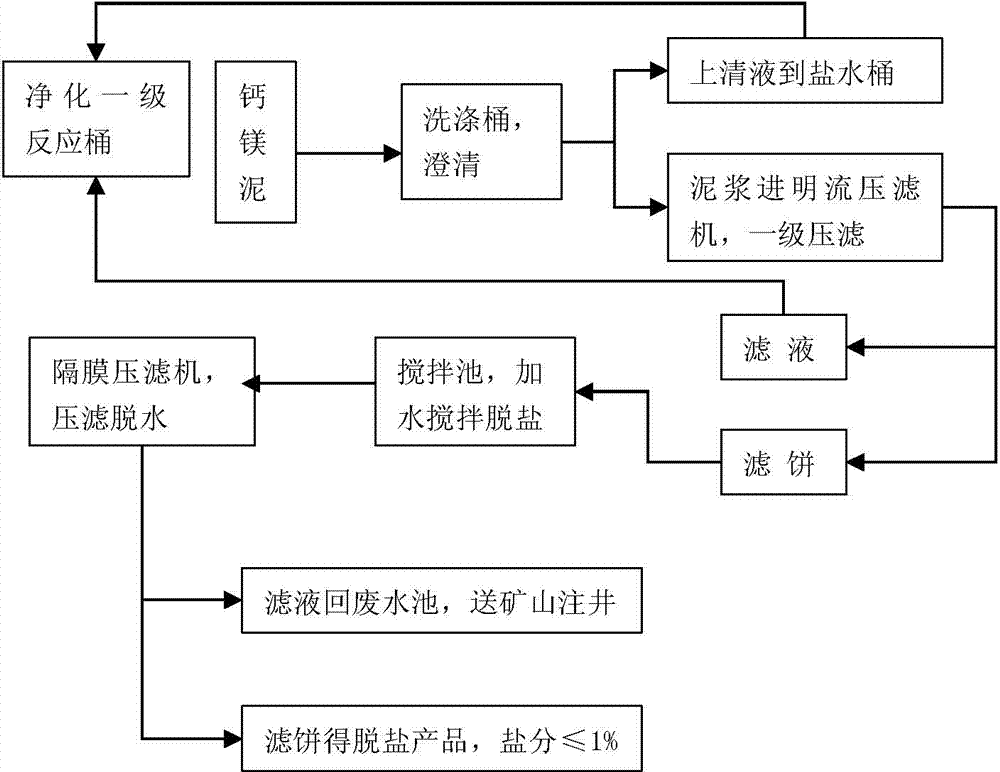

[0026] A method for desalination of two-step calcium magnesium mud, it comprises the following steps:

[0027] The first step, the first-grade calcium magnesium mud desalination, it includes the following steps:

[0028] A: Gypsum and Mg(OH) produced by the primary reaction of brine purification 2 After the waste residue is transported to the washing tank by the mud pump, the supernatant is put into the brine tank after clarification, and then the brine is pumped to the primary reaction tank to participate in the purification reaction, and the remaining gypsum slurry is pumped by the mud pump to the open flow filter press Carry out one-level pressure filtration, and the filtrate after pressure filtration is sent to the first-level reaction tank by centrifugal pump to participate in the purification reaction. The water content of the salt-containing gypsum filter cake after pressure filtration is 25-30%, and the salt content is 10-16%;

[0029] B: Put the salt-containing g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com