Method for producing sulfuric acid from electrolytic manganese residues

A technology for electrolyzing manganese slag and sulfuric acid, which is applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., and can solve problems such as low utilization rate and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

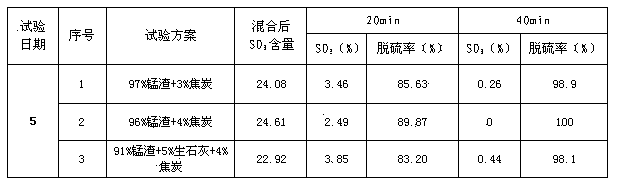

Examples

Embodiment Construction

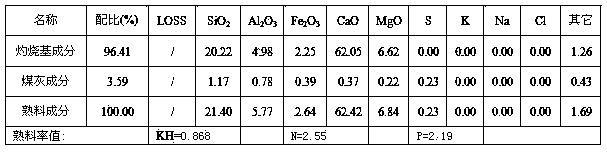

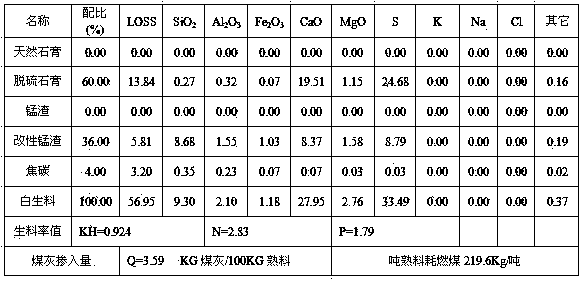

[0017] A method for producing sulfuric acid by using electrolytic manganese slag, the steps of the production process include: (1) drying treatment of electrolytic manganese slag; (2) adding coke and lime for raw material preparation (3) fine grinding; (4) raw material (5) Calcination of raw materials; (6) Production of acid from calcination flue gas.

[0018] The specific process includes:

[0019] (1) Pretreatment of manganese slag: the original manganese slag (with a moisture content of about 25%) is dried with a downstream rotary dryer to a moisture content of less than 2%, and the dried manganese slag enters the plant for sulfuric acid production. The raw material batching station is waiting for batching. The batching is measured by a belt weighing scale;

[0020] (2) Raw material batching: The batching station uses an 8-meter round warehouse for various material blending, and the raw materials that need to be blended are coke, manganese slag, industrial gypsum and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com