Design method for anti-blocking sprayer

A design method and nozzle technology, applied in separation methods, chemical instruments and methods, spray devices, etc., can solve the problems of atomization performance damage, blocking nozzles, and dripping phenomenon, so as to increase atomization performance, increase Large spray angle and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

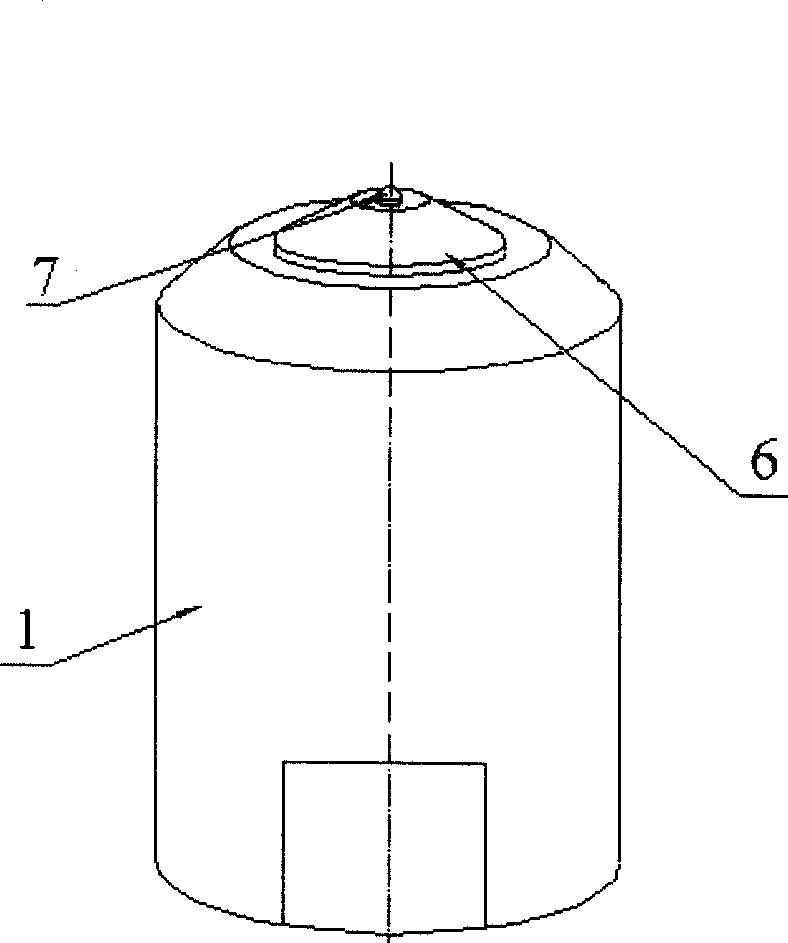

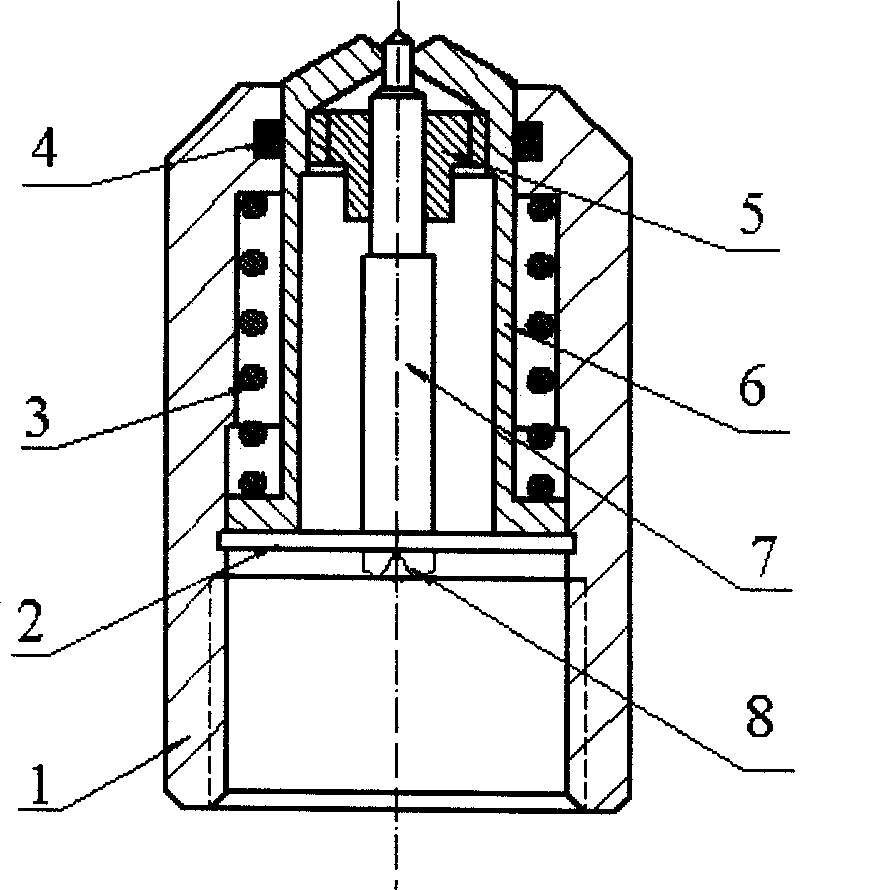

[0016] Example 1 as figure 1 with figure 2 As shown, it is an anti-blocking single-nozzle nozzle. When there is a single nozzle on the top of the center of the housing 1, a spring 3 is sleeved between the piston 10 in the housing 1 and the housing 1, and the bottom end of the spring 3 is placed on the piston. 10, the bottom edge of the piston 10 is placed on the card 2, the cyclone 5 is set on the top of the inner cavity of the piston 10, and the cyclone 5 is sleeved with a single-mouth needle 7, and the single-mouth needle 7 is fixed On the card 2; the bottom end of the housing 1 has a mouthpiece 13 cavity. The top of the single-mouth needle 7 is set on the outlet of the cyclone 5, and the outlet of the cyclone 5 corresponds to the mouth of the nozzle, and the centerline of the single-mouth needle 7 and the centerline of the outlet of the cyclone 5 And the center line of mouth of nozzle of nozzle overlaps mutually in the axial direction, when the top of housing 1 has a noz...

Embodiment 2

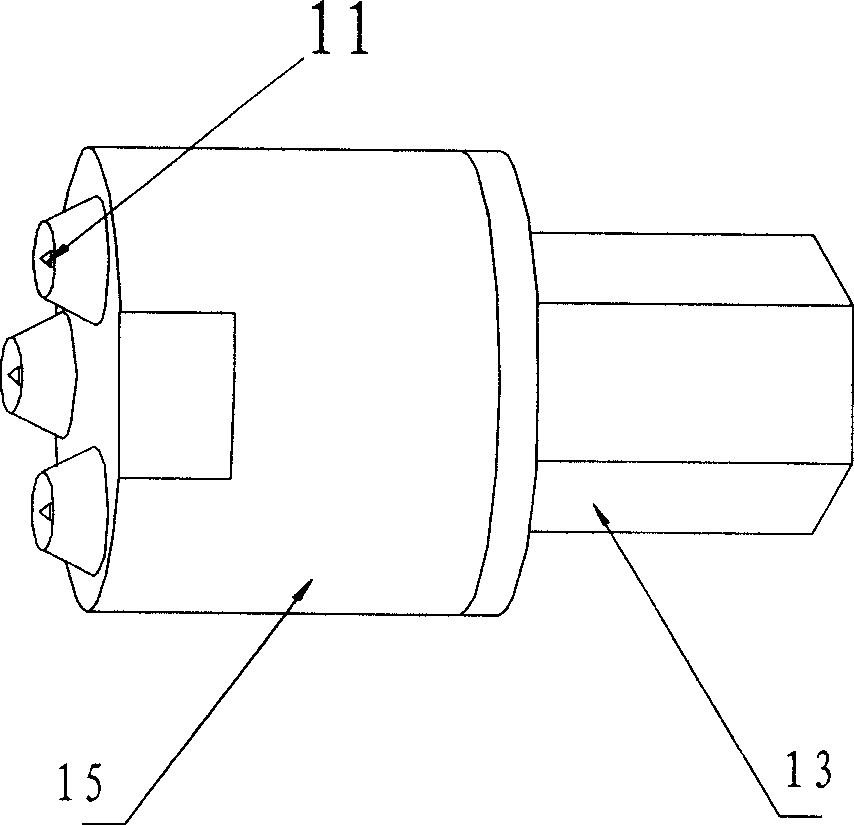

[0018] Embodiment 2 is an anti-blocking multi-nozzle nozzle such as image 3 with Figure 4 As shown, it is an anti-blocking multi-nozzle nozzle. There are multiple nozzles on the top of the multi-mouth housing 15, and a multi-mouth cyclone 16 is set inside each nozzle, and a multi-mouth poking needle 11 is sleeved in each multi-mouth cyclone 16, and the multi-mouth cyclone 16 and the needle 11 are all connected to the top of the piston, the inner cavity of the piston is covered with a spring 14, the bottom of the spring 14 and the lower part of the piston are embedded in the groove at the top of the mouthpiece 13, and the mouthpiece 13 is sealed and connected to the multi-piece by the sealing ring 12. Mouth housing 15 bottoms.

[0019] When installing, first press the multi-nozzle cyclone 16 into the multi-nozzle housing 15, put the piston "O" type seal ring 9 into the piston seal ring groove, and put the nozzle "O" type seal ring 12 into the nozzle 13 in the sealing groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com