Method for removing nitrogen oxide in flue gas, and nano flue gas denitration system

A technology of nitrogen oxides and flue gas, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., can solve the problems of increasing manufacturing and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

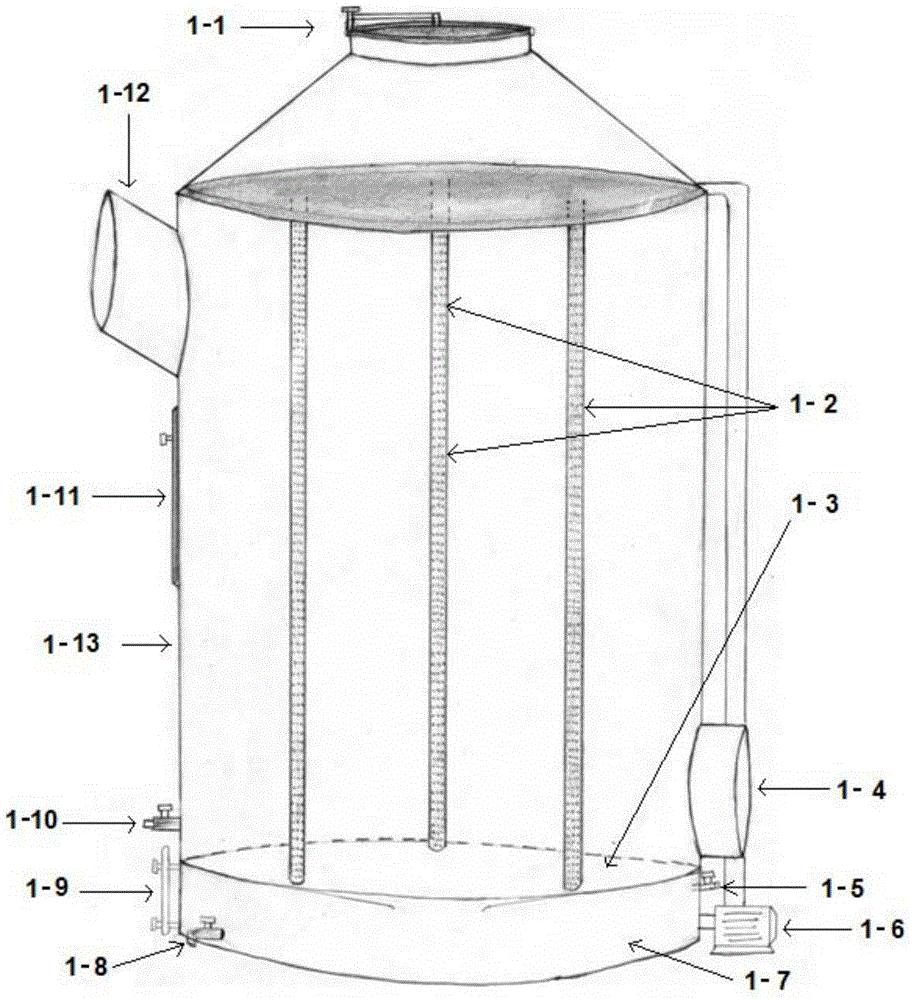

[0079] Embodiment 1: a kind of method for eliminating nitrogen oxides in flue gas is characterized in that it comprises the following steps:

[0080] (1) The flue gas containing nitrogen oxides is pretreated in the pretreatment container. The pretreatment process removes solid particles with a diameter greater than 10 microns in the flue gas and oxidizes NO to NO 2 :

[0081] A solution containing an oxidizing agent and having a pH value less than or equal to 3 is added to the pretreatment container;

[0082] Pass the flue gas into the pretreatment container, fully contact with the liquid, so that the solid particles with a diameter greater than 10 microns remain in the solution, and NO is oxidized to NO 2 ;

[0083] Export the solution containing solid particles out of the pretreatment container;

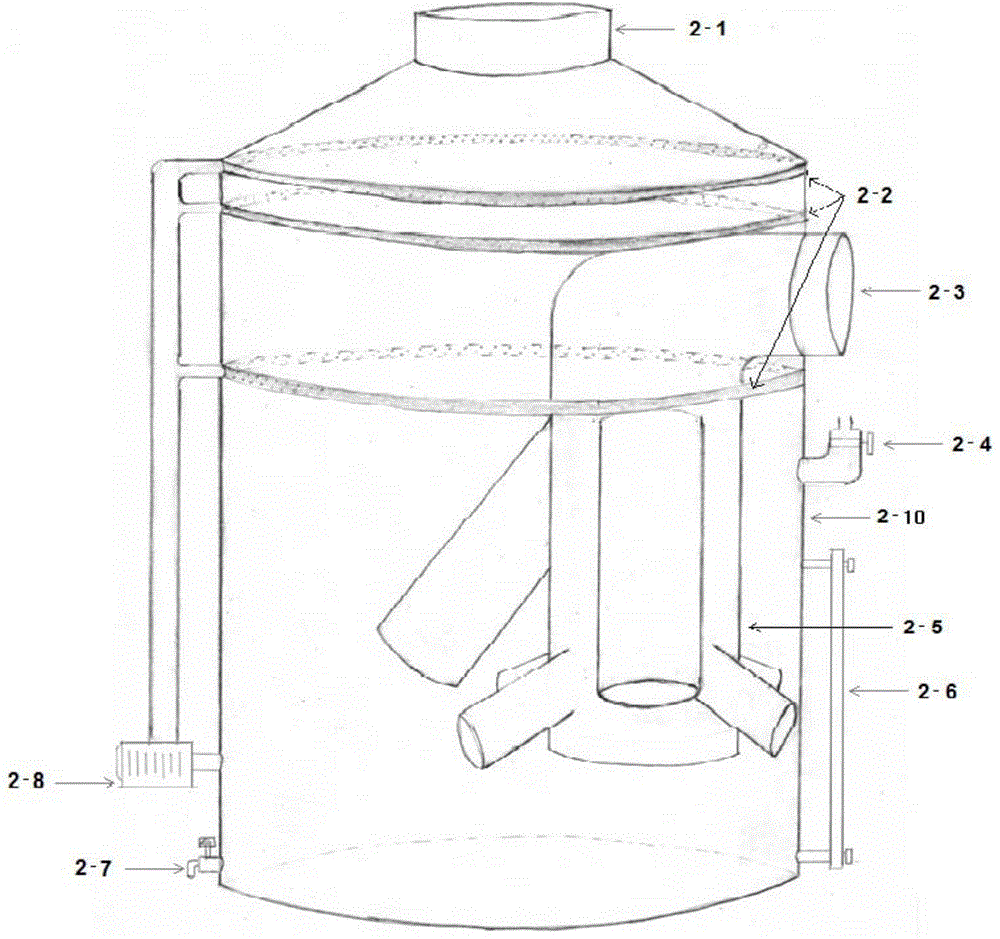

[0084] (2) The pretreated flue gas enters the denitrification container, and the nitrogen oxides react with the oxidant to generate nitric acid:

[0085] A solution containing ...

Embodiment 2

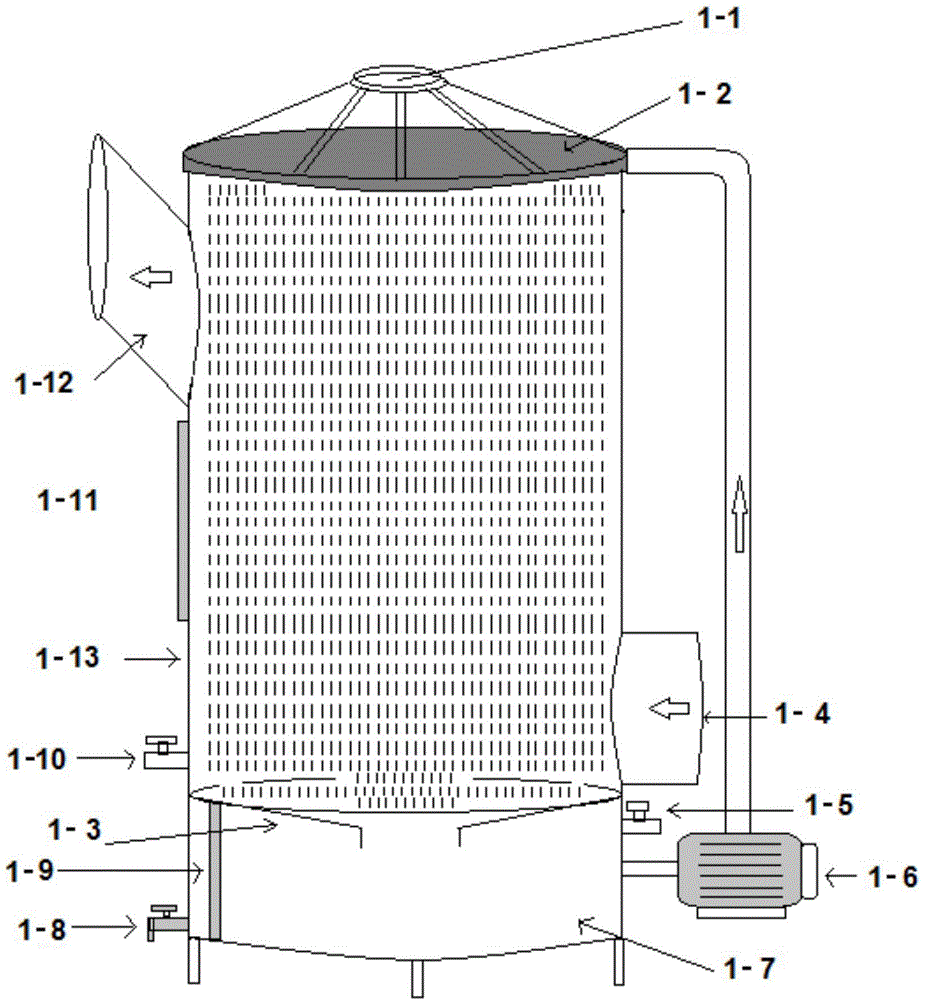

[0127] Embodiment 2: a kind of method for eliminating nitrogen oxides in flue gas is characterized in that it comprises the following steps:

[0128] (1) The flue gas containing nitrogen oxides is pretreated in the pretreatment container. The pretreatment process removes solid particles with a diameter greater than 10 microns in the flue gas and oxidizes NO to NO 2 :

[0129] A solution containing an oxidizing agent and having a pH value less than or equal to 3 is added to the pretreatment container;

[0130] Pass the flue gas into the pretreatment container, fully contact with the liquid, so that the solid particles with a diameter greater than 10 microns remain in the solution, and NO is oxidized to NO 2 ;

[0131] Export the solution containing solid particles out of the pretreatment container;

[0132] (2) The pretreated flue gas enters the denitrification container, and the nitrogen oxides react with the oxidant to generate nitric acid:

[0133] A solution containing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com