Method for reducing difference of two sides of paper, and prepared paper

A two-sided, paper-based technology, applied in the field of papermaking, can solve problems such as differences in fiber composition, achieve the effects of overcoming fluctuations in coalescence ability, improving distribution uniformity, and reducing the difference between two sides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example 1 A glass fiber paper with low double-sided difference

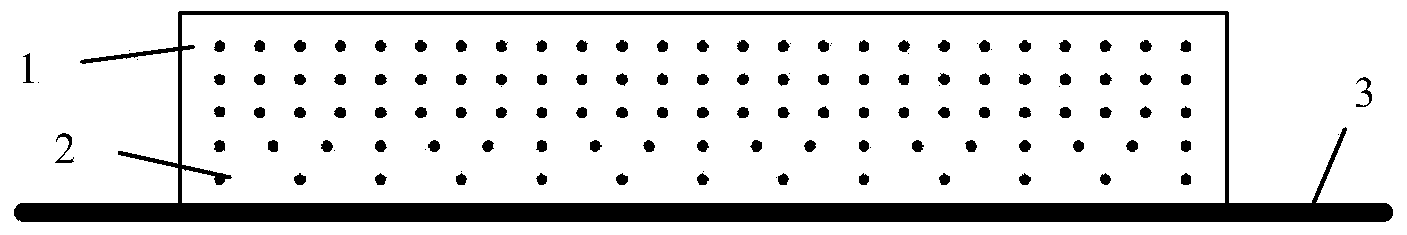

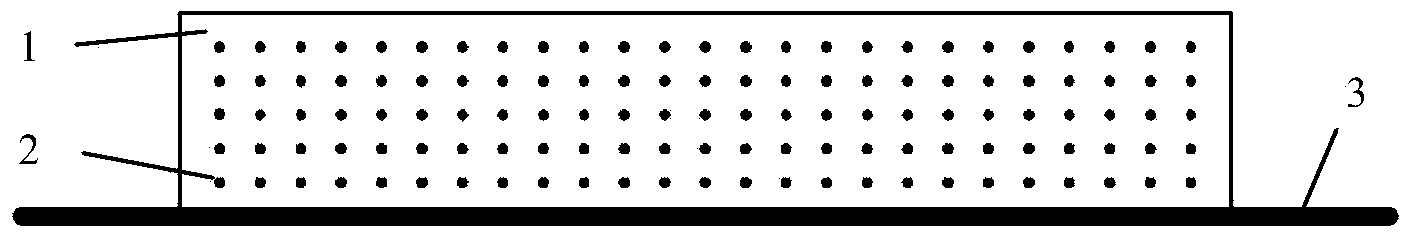

[0060] A glass fiber paper with low two-sidedness, basis weight 85g / m 2 , consisting of two fiber layers, prepared by the following method:

[0061] 1. Each layer is prepared and flowed separately

[0062] The raw materials are mixed with water according to the formula shown in Table 1, dispersed and diluted to a solid weight percent concentration of 0.8%, to obtain slurry I and slurry II, wherein the content of borate fine glass wool fibers in slurry I is higher than that of slurry 7.5% more II;

[0063] 2. Copy into shape

[0064] Slurry I and II are respectively sent to the multi-channel inclined wire paper machine, wherein the slurry I enters the flow channel close to the forming area, and the two layers are simultaneously sheeted and formed, and after dehydration treatment, sizing, drying, and curling, the target paper is obtained. product. The first layer of the glass fiber paper with low doub...

Embodiment 2

[0065] Example 2 A glass fiber paper with low double-sided difference

[0066] A glass fiber paper with low two-sidedness, basis weight 85g / m 2 , consisting of three fiber layers, prepared by the following method:

[0067] 1. Each layer is prepared and flowed separately

[0068] The raw material is mixed with water according to the formula shown in Table 1, dispersed, diluted to a solid weight percent concentration of 0.67%, to obtain slurry I, slurry II and slurry III, wherein the borate fine glass wool fiber in slurry I Content is 7.5% more than slurry II and slurry III;

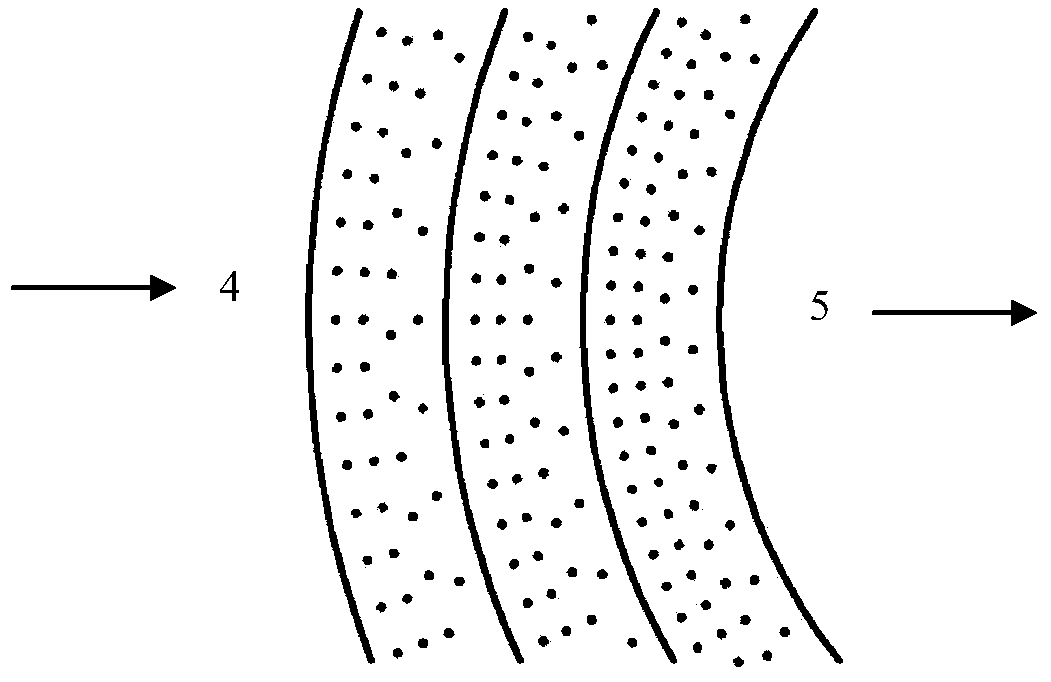

[0069] 2. Copy into shape

[0070] Slurries I, II, and III are sent to the multi-channel inclined-wire paper machine respectively, and the slurry I enters the flow channel close to the forming area, and the three layers are simultaneously copied and formed. After dehydration treatment, sizing, drying, and curling, that is get the target product. For the glass fiber paper with low two-sided differenc...

Embodiment 3

[0071] Example 3 A glass fiber paper with low double-sided difference

[0072] A glass fiber paper with low two-sidedness, basis weight 85g / m 2 , consisting of three fiber layers, prepared by the following method:

[0073] 1. Each layer is prepared and flowed separately

[0074] Prepare each raw material according to the formula shown in Table 1, then mix with water, disperse, and dilute to a solid weight percentage concentration of 0.67%, to obtain slurry I, slurry II and slurry III, wherein the alkali-free fine glass wool in slurry I The fiber content is 5% more than pulp II and pulp III;

[0075] 2. Copy into shape

[0076] Slurries I, II, and III are sent to the multi-channel inclined-wire paper machine respectively, and the slurry I enters the flow channel close to the forming area, and the three layers are simultaneously copied and formed. After dehydration treatment, sizing, drying, and curling, that is get the target product. For the glass fiber paper with low t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Inner diameter φ | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com