Polyamide/oligomeric silsesquioxane nano-hybrid material and preparation method thereof

A technology of polysilsesquioxane and nano-hybrid materials, which is applied in the field of star-shaped high-fluidity polyamide/oligomeric silsesquioxane nano-hybrid materials and its preparation, can solve polyamide fluidity and thermal /Mechanical property conflicts and other issues, to achieve the effect of high melt fluidity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

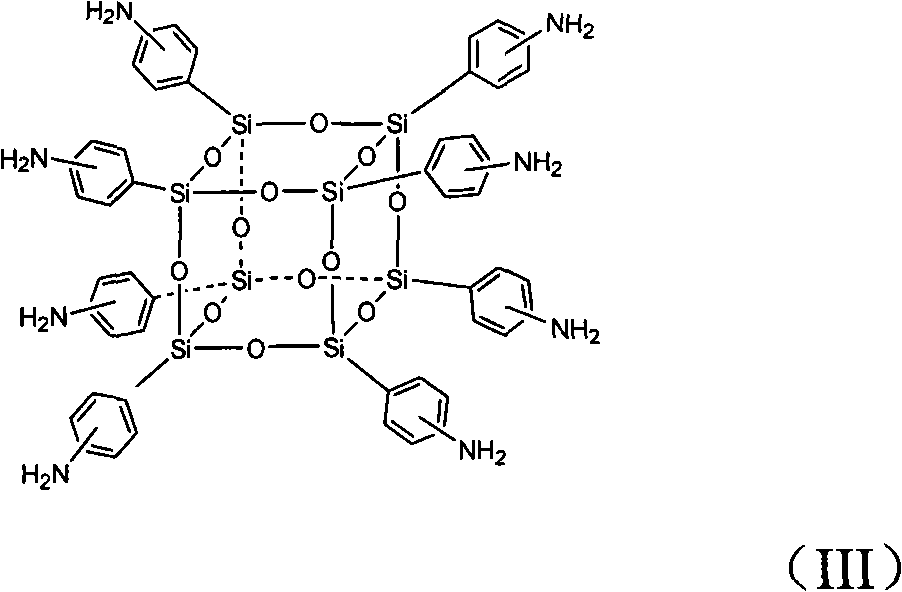

[0057] Modification of oligosilsesquioxane:

[0058] 1) Under a nitrogen atmosphere, 2.91 g of BTDA was dissolved in N-methylpyrrolidone, and after being fully dissolved, a solution of 1.3 g of OAPS was added dropwise thereto. After completion, react at 30°C for 20 hours under a nitrogen atmosphere to obtain an oligomeric silsesquioxane with an anhydride functional group at the end;

[0059] 2) Weighing 1.17 g of aminocaproic acid and adding it to the above-mentioned oligomeric silsesquioxane solution with an anhydride functional group at the end, reacting at 30° C. for 20 hours under a nitrogen atmosphere to obtain an initiator-modified oligomeric silsesquioxane solution;

[0060] 3) The initiator-modified oligomeric silsesquioxane solution obtained in step 2) is dropped into water for precipitation, and the precipitate is collected and dried to obtain the initiator-modified oligomeric silsesquioxane.

Embodiment 2

[0062] Modification of oligosilsesquioxane:

[0063] 1) Under a nitrogen atmosphere, put 50 g of caprolactam and 1.08 g of BTDA in a three-necked flask and melt at 90° C.; after they are completely melted, add dropwise an acetone solution of 0.48 g of octaaminophenylsilsesquioxane therein. After completion, react at 90°C for 14 hours under a nitrogen atmosphere to obtain an oligomeric silsesquioxane with an anhydride functional group at the end;

[0064] 2) Weighing 0.43 g of aminocaproic acid and adding it to the above-mentioned oligomeric silsesquioxane solution with an anhydride functional group at the end, and reacting at 90° C. for 10 hours under a nitrogen atmosphere to obtain an initiator-modified oligomeric silsesquioxane solution;

[0065] 3) The initiator-modified oligomeric silsesquioxane solution obtained in step 2) is poured into a petri dish, and cooled to obtain an initiator-modified oligomeric silsesquioxane with a content of 5% in the caprolactam monomer. % o...

Embodiment 3

[0067] Modification of oligosilsesquioxane:

[0068] 1) Under a nitrogen atmosphere, put 45g of caprolactam and 3.47g of BTDA in a three-necked flask and melt at 90°C; after they are completely melted, 1.55g of octaaminophenylsilsesquioxane in acetone is added dropwise thereto. After completion, react at 90°C for 24 hours under a nitrogen atmosphere to obtain an oligomeric silsesquioxane with an anhydride functional group at the end;

[0069] 2) Weighing 1.39 g of aminocaproic acid and adding it to the above-mentioned oligomeric silsesquioxane solution with an anhydride functional group at the end, reacting at 90° C. for 24 hours under a nitrogen atmosphere to obtain an initiator-modified oligomeric silsesquioxane solution;

[0070] 3) Pour the initiator-modified oligomeric silsesquioxane solution obtained in step 2) into a petri dish, and cool to obtain the initiator-modified oligomeric silsesquioxane in the caprolactam monomer with a content of 18 % of composite prepolymer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com