Coated paper and its manufacturing method

A manufacturing method and technology of coated paper, applied in the field of papermaking, can solve the problems of large surface roughness and affect the surface printing performance of coated paper, and achieve the effect of good surface printing performance and small roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

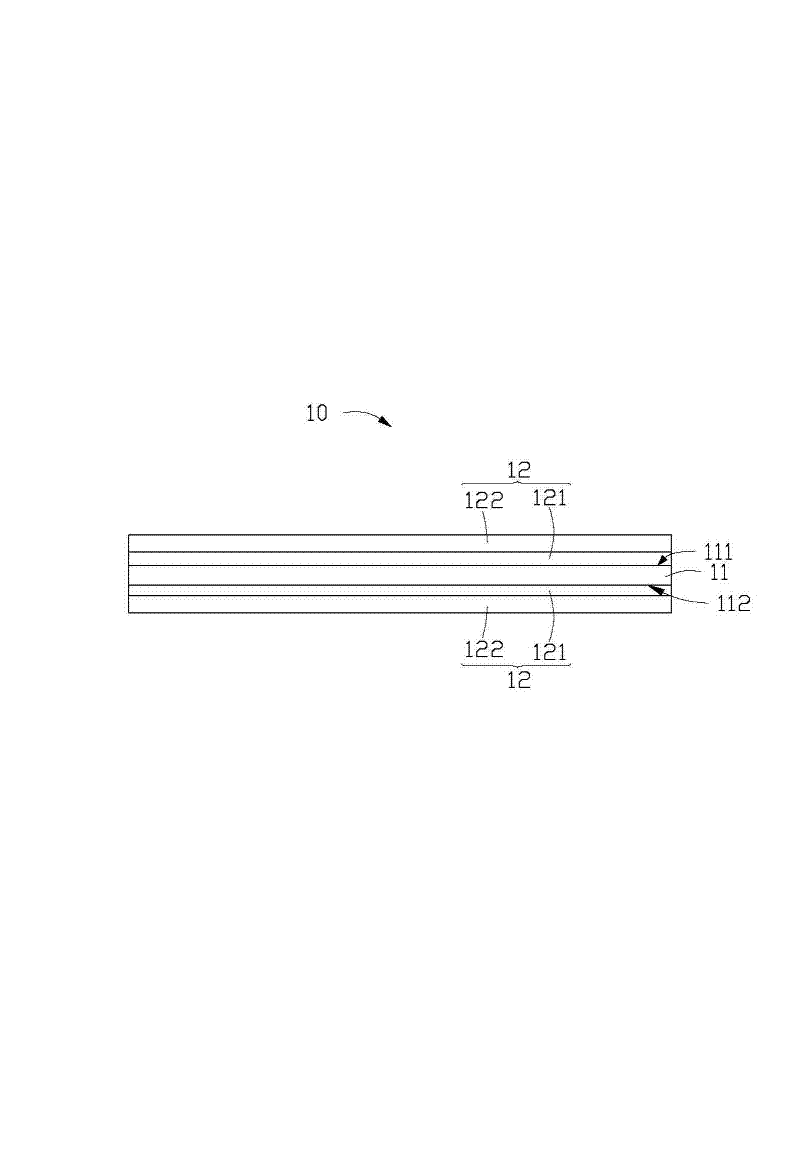

[0013] The coated paper provided by the present invention and its manufacturing method will be further described in detail below in conjunction with the accompanying drawings.

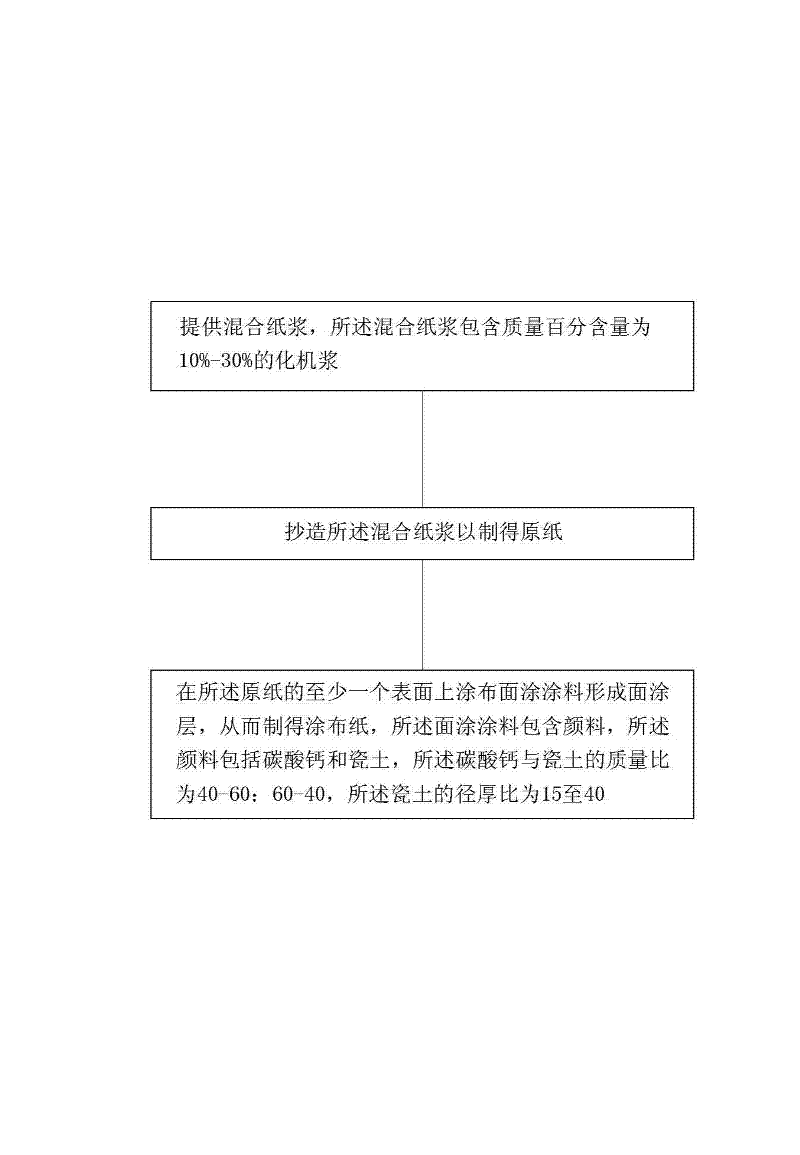

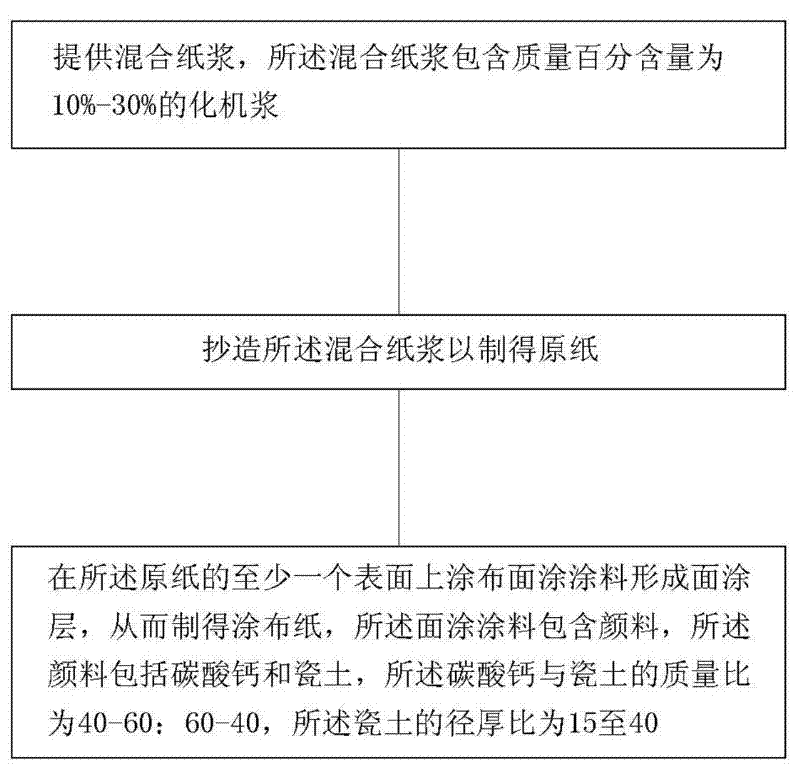

[0014] Please also refer to figure 1 and figure 2 , The invention provides a method for manufacturing coated paper and the prepared coated paper. Described coated paper manufacturing method comprises the following steps:

[0015] In the first step, a mixed pulp is provided.

[0016] The mixed pulp includes chemical-mechanical pulp and chemical pulp. The chemical mechanical pulp refers to bleached chemical thermal mechanical pulp (Bleached Chemical Thermal Mechanical Pulp, BCTMP). The chemical pulp refers to pulp obtained by chemically dissociating plant fibers. The mass percentage of the chemical-mechanical pulp in the mixed pulp is 10%-30%, preferably 15%-30%. The mass percentage of the chemical pulp in the mixed pulp is 70%-90%. In this embodiment, the chemical pulp includes bleached broadlea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com