Pulverizing loop ball mill load control method for cement factory

A ball mill and cement plant technology, applied in the field of control, can solve the problems of the large lagging system, the difficulty of obtaining mathematical models, and the lack of theoretical basis, etc., and achieve the effects of reducing maintenance, increasing the output per hour, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

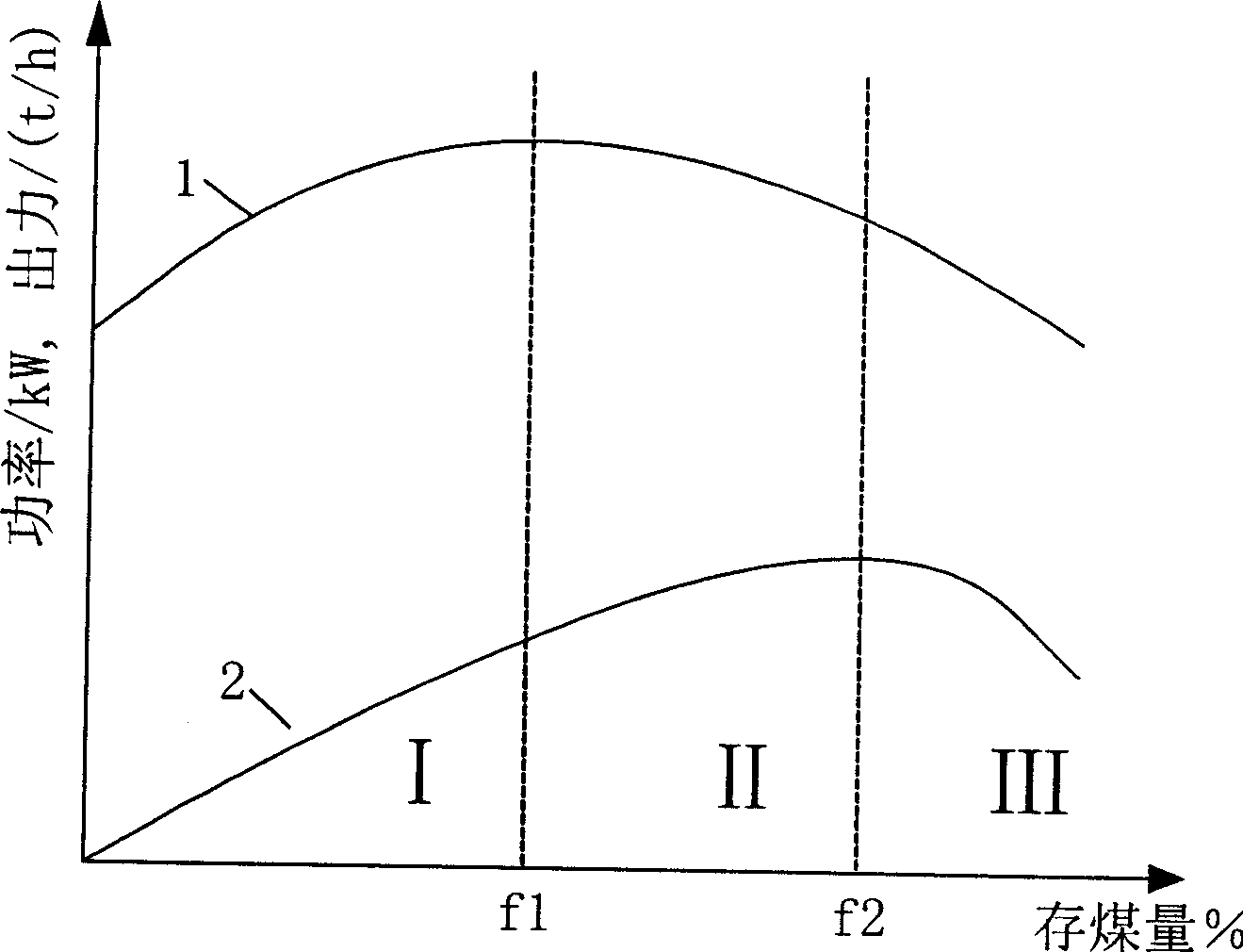

[0020] See figure 1 , The operating law of the ball mill can be intuitively reflected through its working characteristic curve. It can be seen from curve 2 in the figure that an important fact is that the output of the ball mill does not increase monotonously with the increase in the amount of material stored therein, and the power of the ball mill does not increase monotonously with the increase of the amount of material stored in it. Therefore, during the operation of the ball mill, there is indeed an extreme characteristic between the output and the amount of coal.

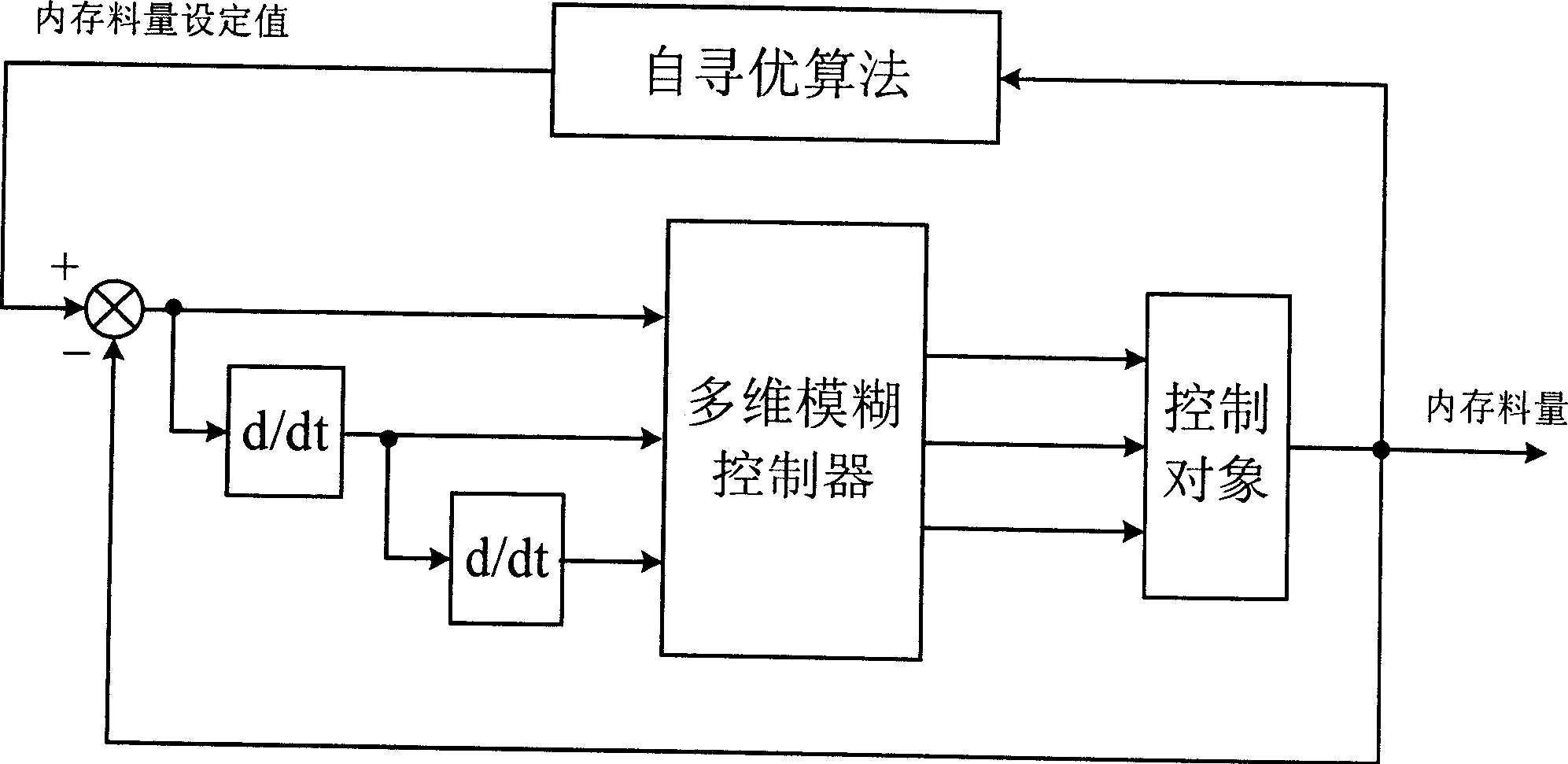

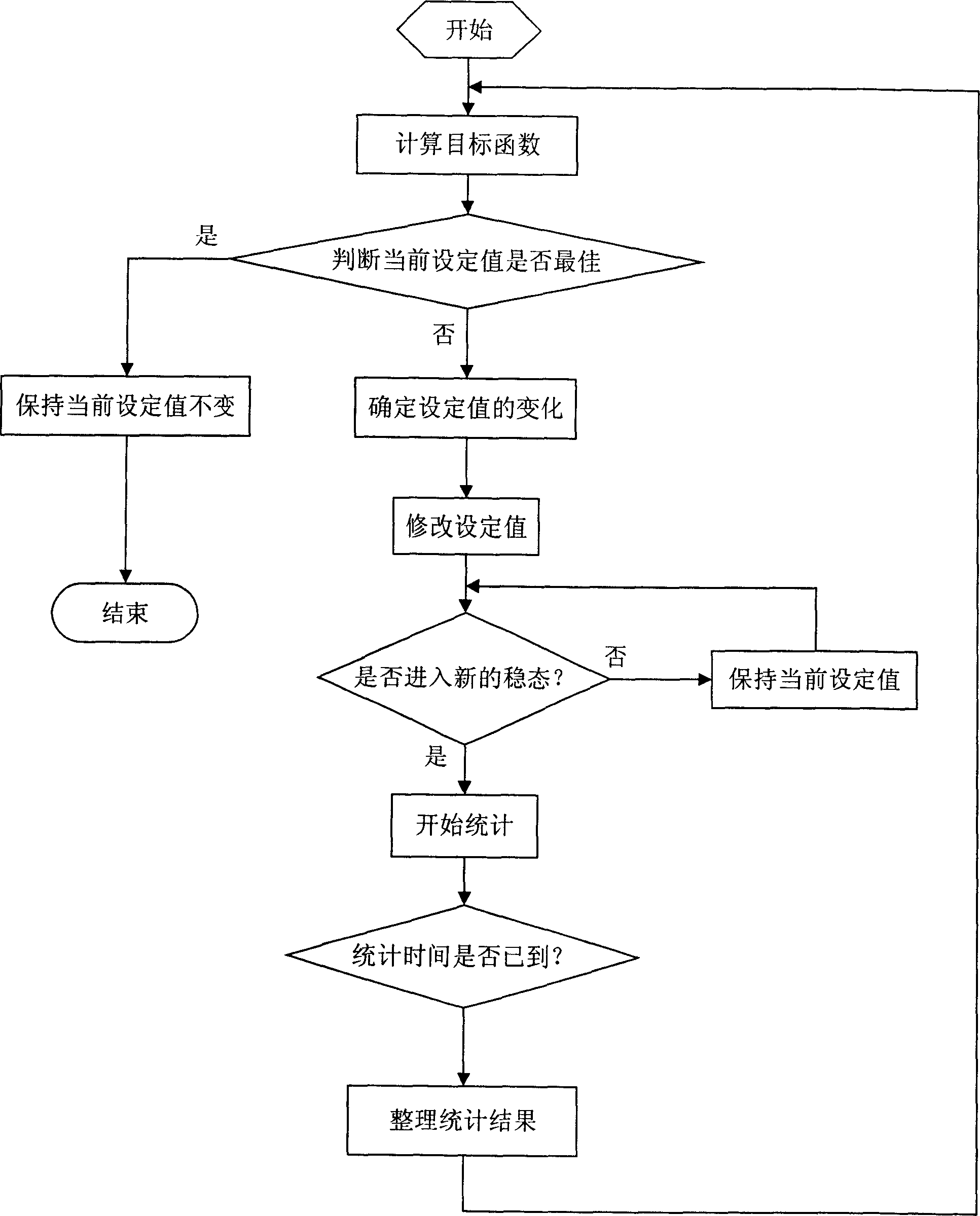

[0021] The load control method of the grinding loop ball mill in the cement plant of the present invention adopts a two-layer control structure, the upper layer is a self-optimizing algorithm and the lower layer is a multi-dimensional fuzzy control algorithm. The specific control block diagram is shown in the attachment figure 2 . The upper layer self-optimization algorithm changes the set value of the ball mill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com