Patents

Literature

54results about How to "Avoid material break" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

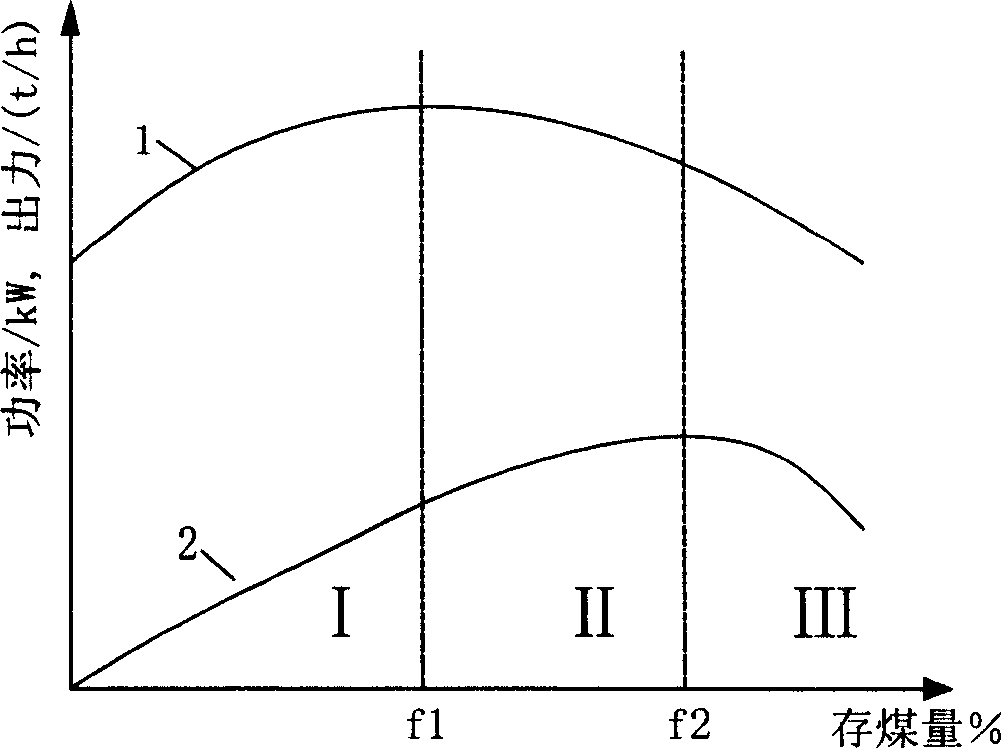

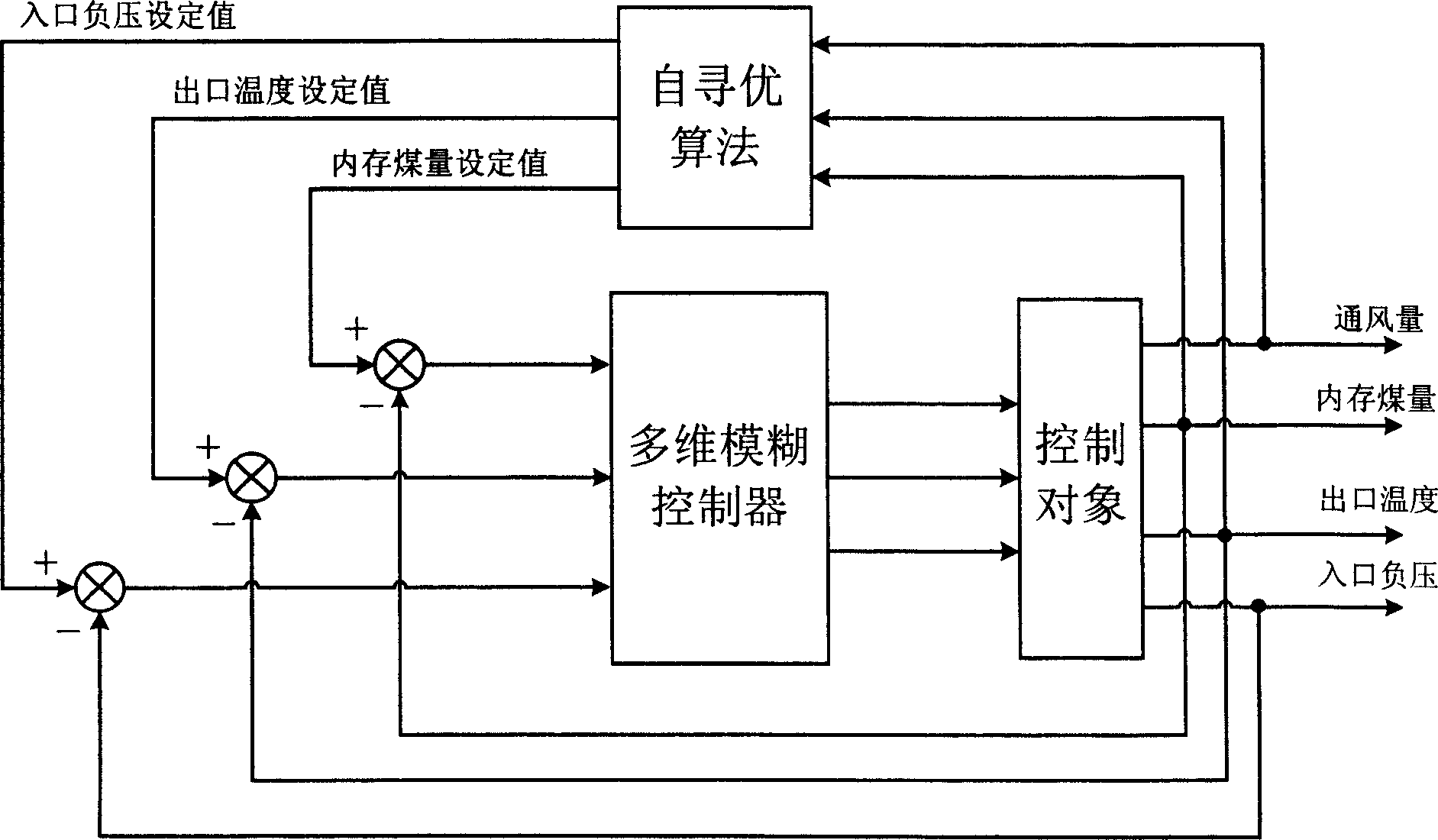

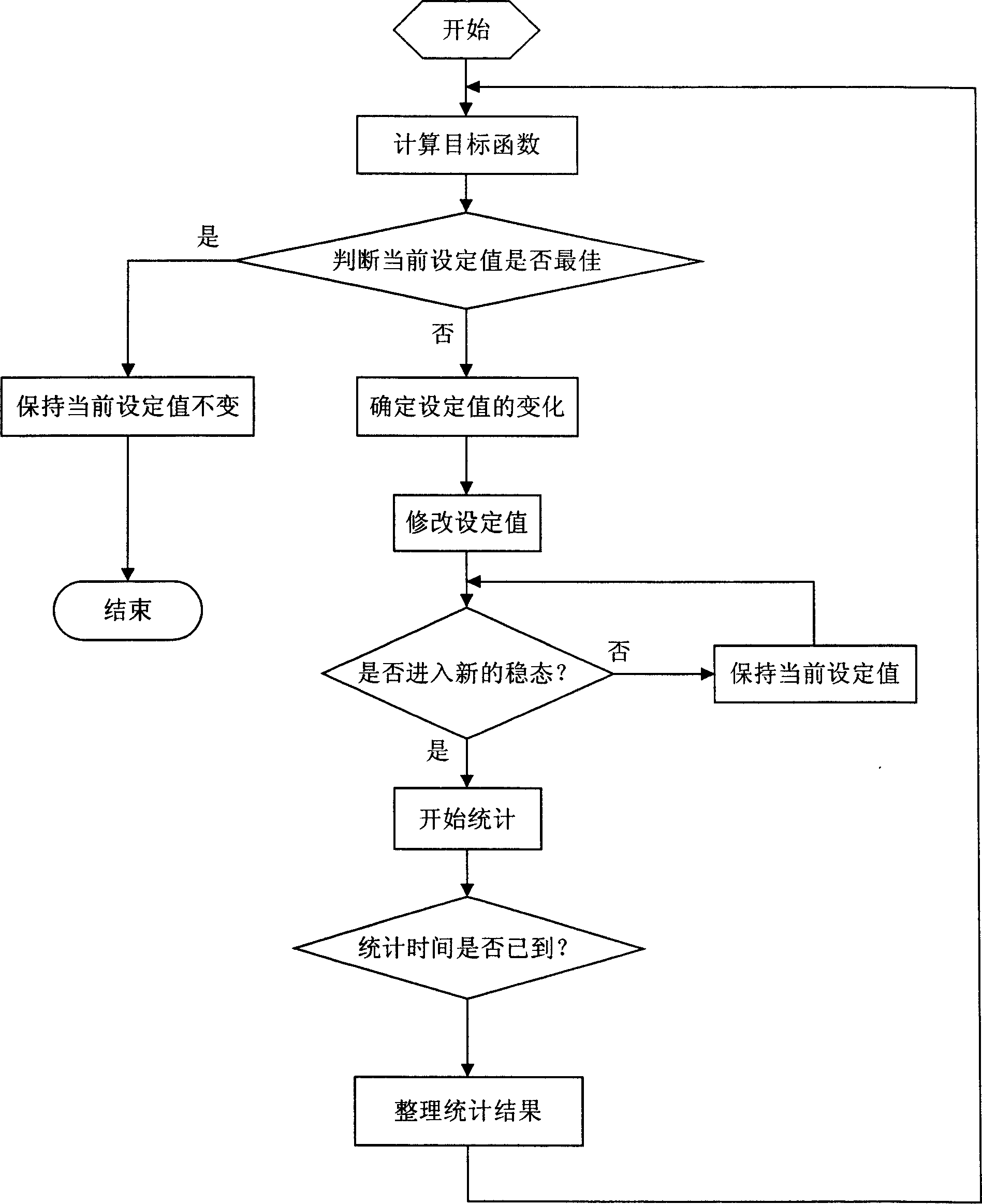

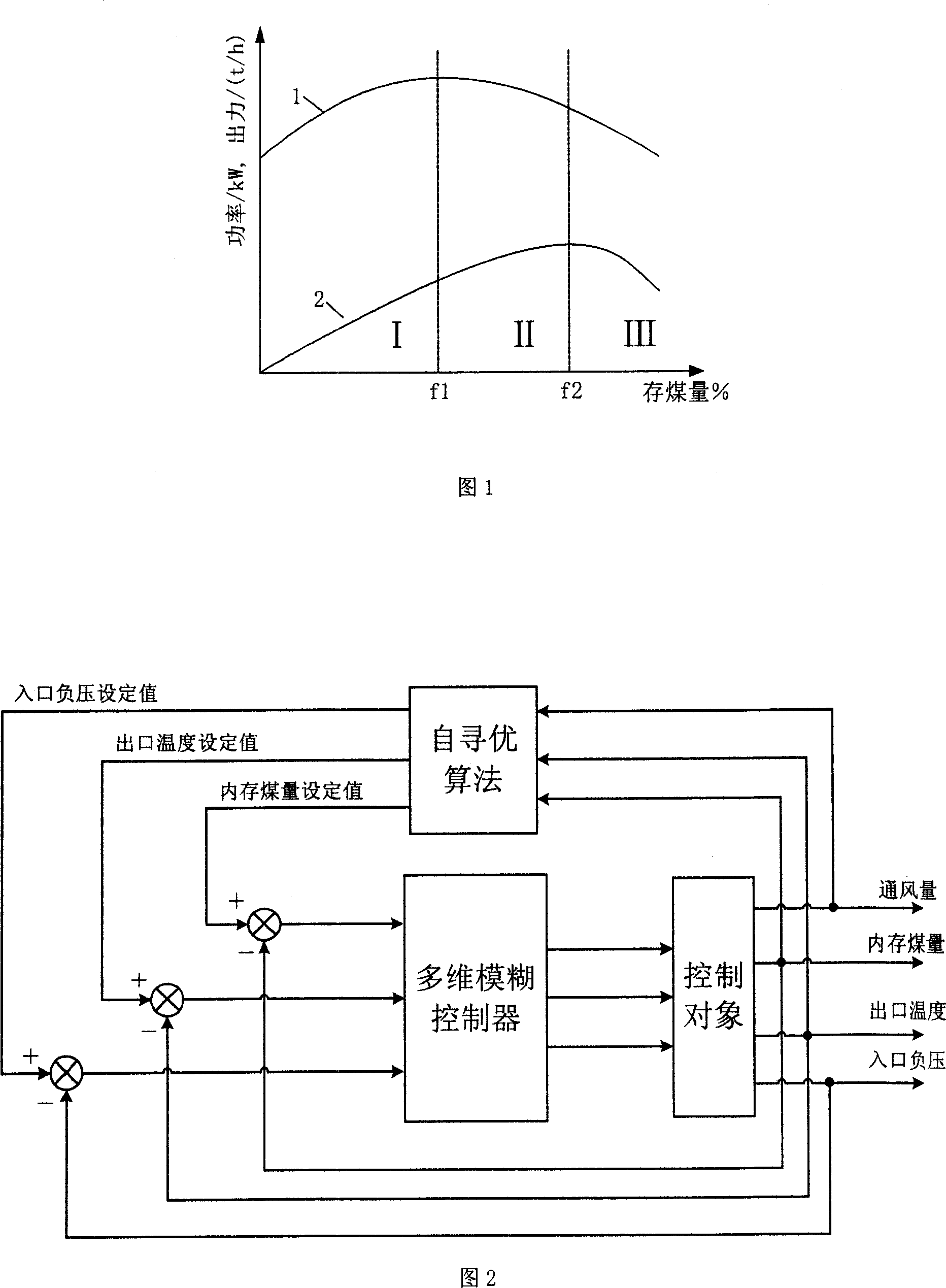

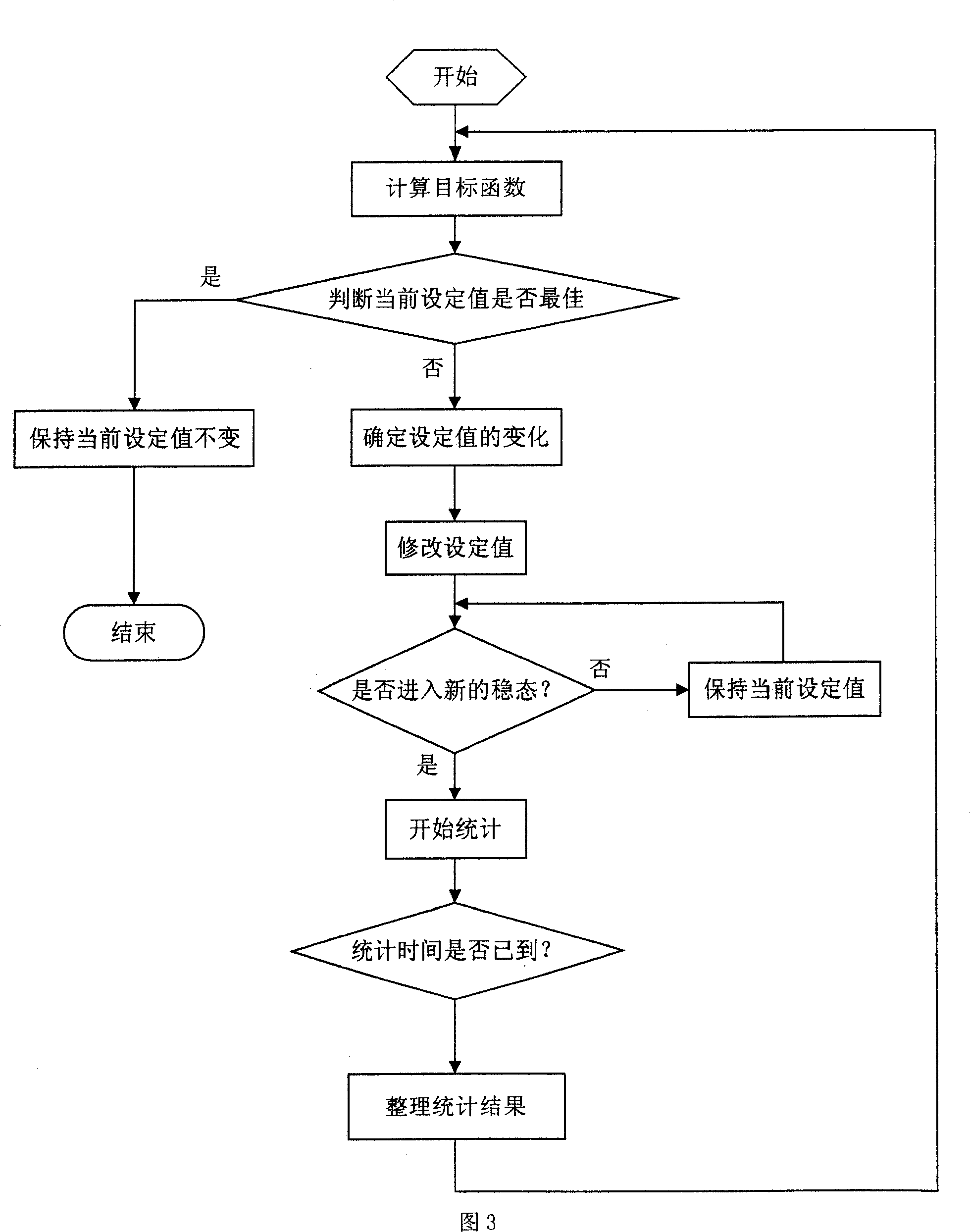

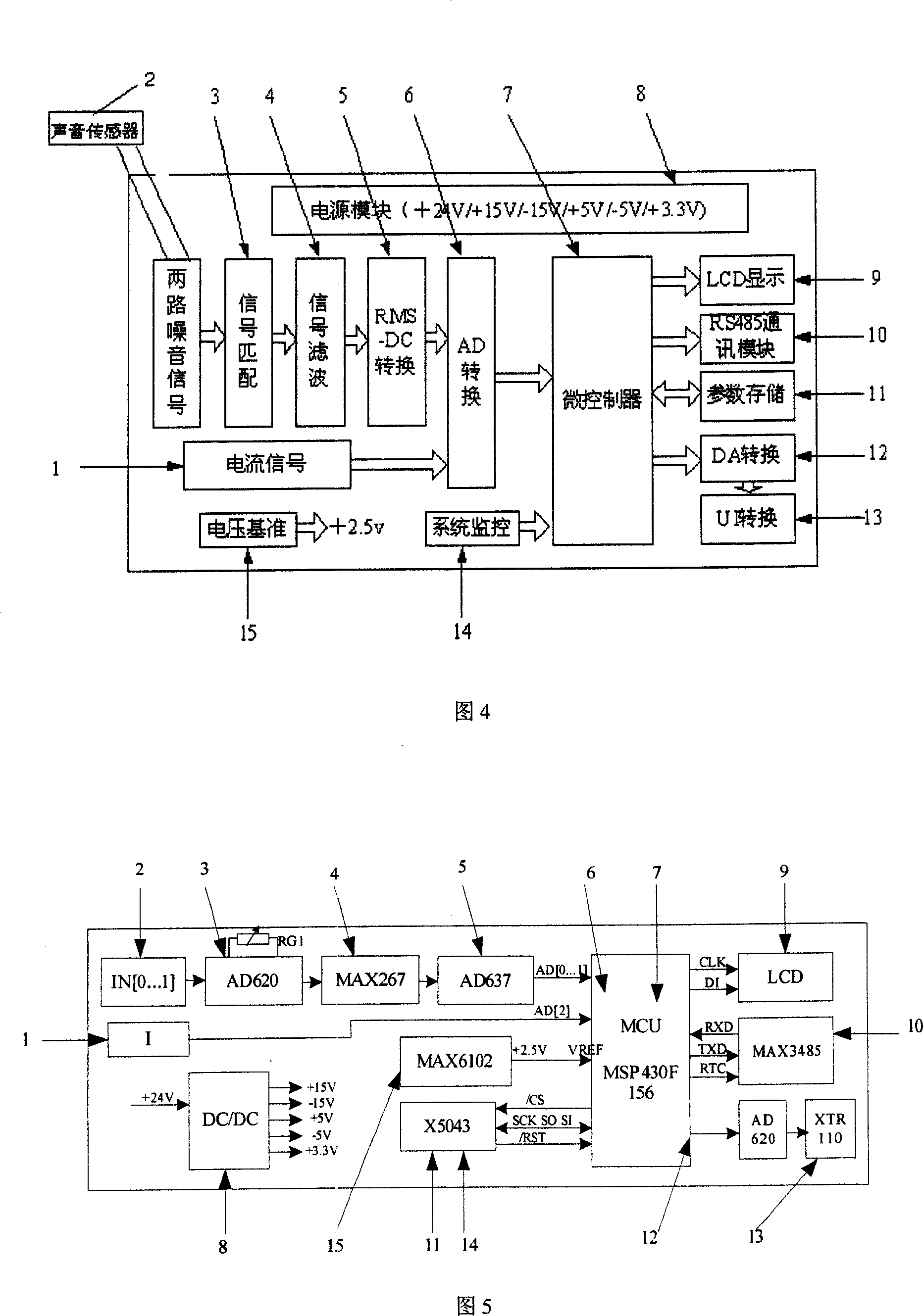

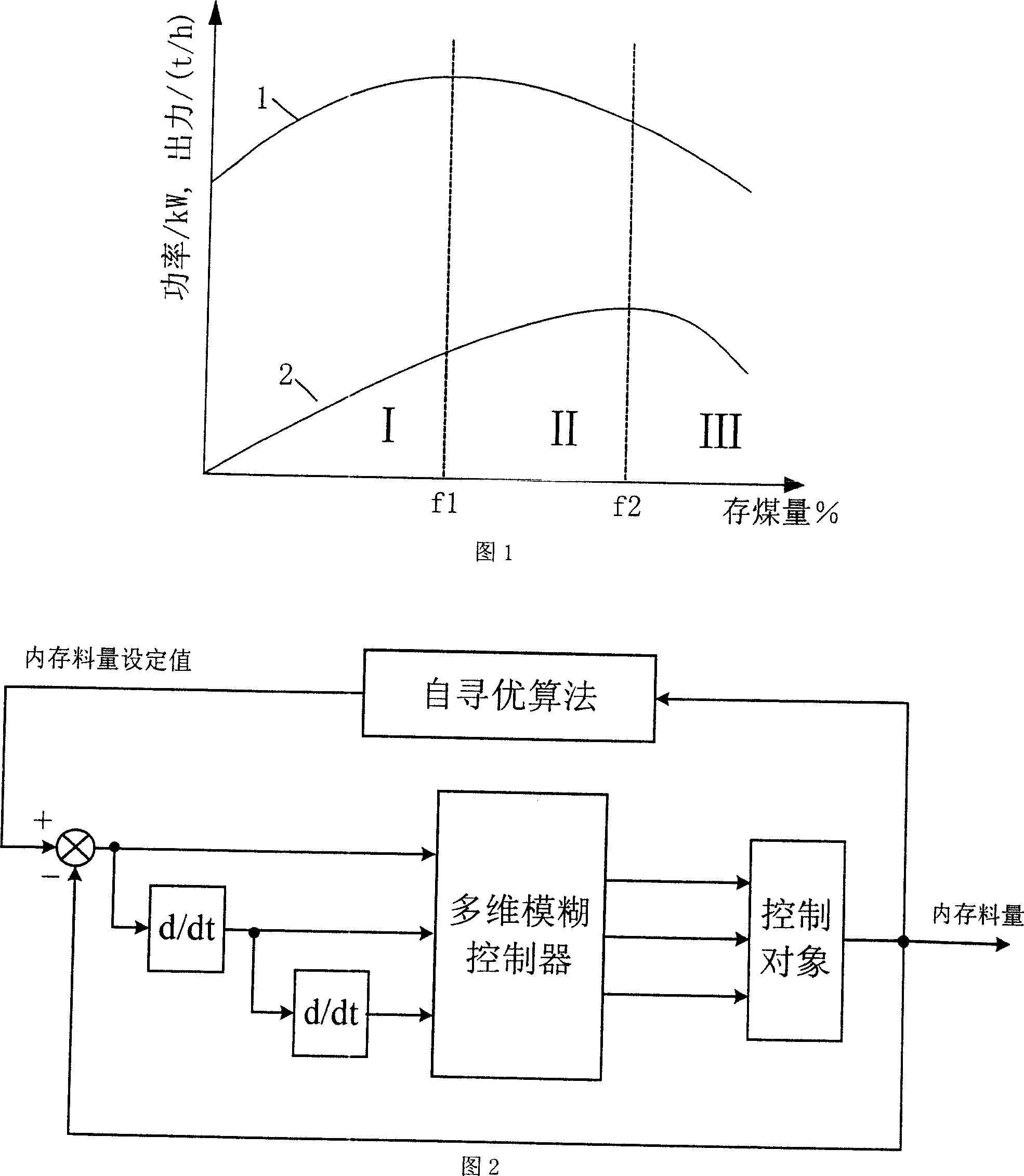

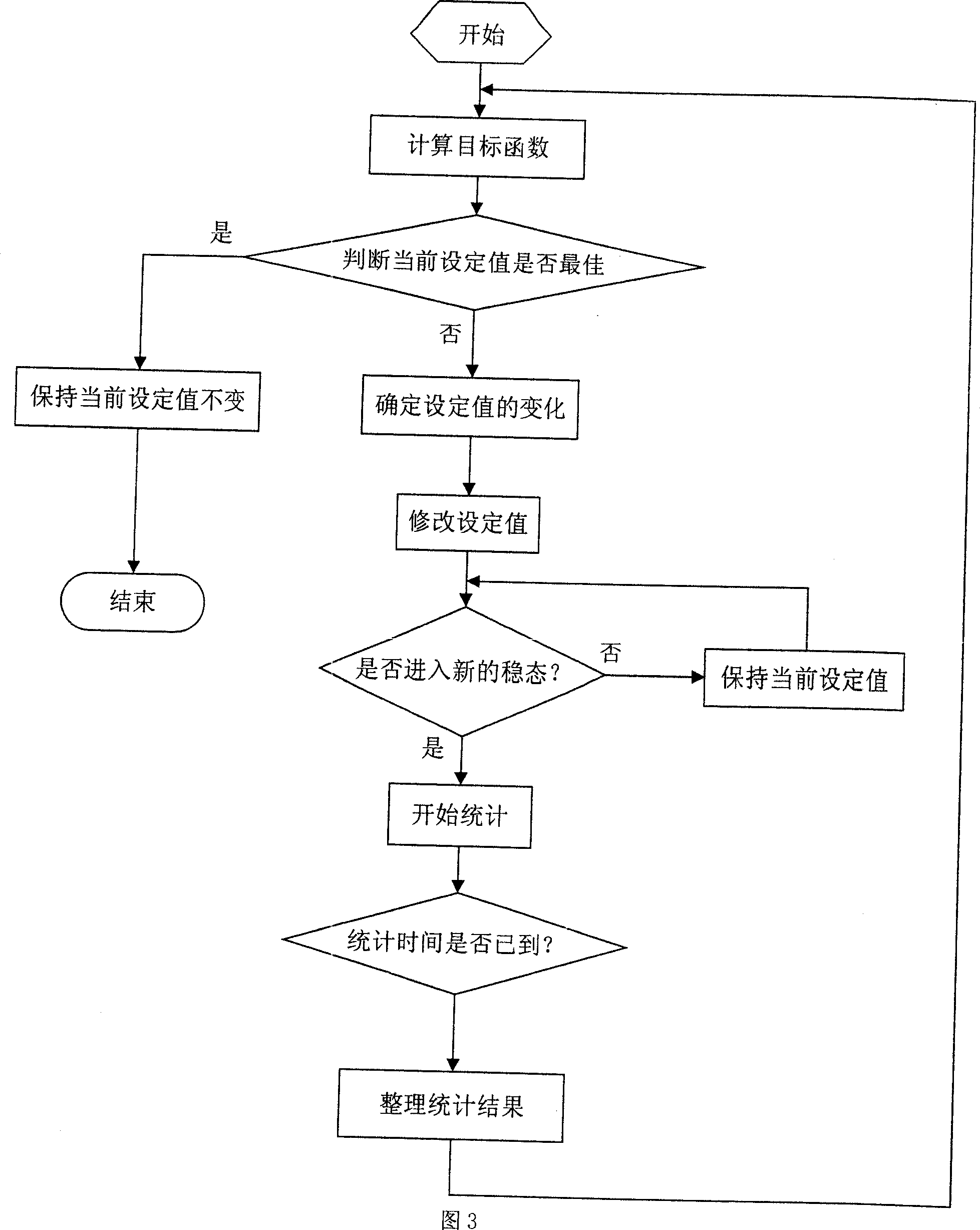

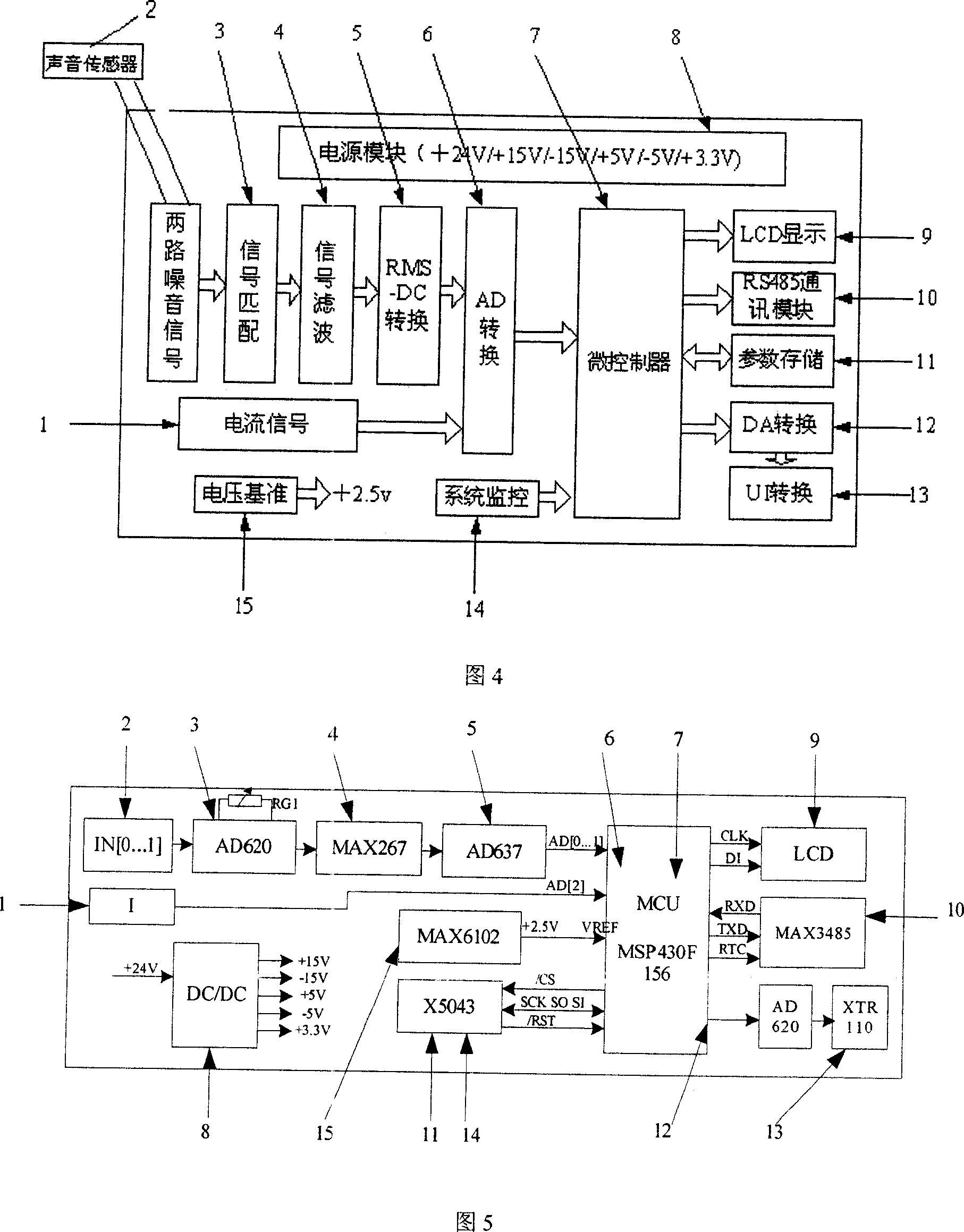

Powder-making system automatic control method for heat engine plant steel ball coal grinding mill

The automatic control method for steel ball coal mill in thermal power plant adopts a double-layer control structure, including an upper layer of self optimizing algorithm and a lower layer of multidimensional fuzzy control algorithm. The self optimizing algorithm finds out the optimal inside coal storage quantity inside the coal mill, the optimal outlet temperature of the coal mill and the optimal inlet negative pressure value of the coal mill as the controlling set values; and the multidimensional fuzzy control algorithm realizes the automatic regulation of the coal feed quantity, the hot air valve opening, and the recirculating air valve opening or the cold air valve opening, so as to ensure the safe and reliable running of the steel ball coal mill system in optimal mode.

Owner:XI AN JIAOTONG UNIV +1

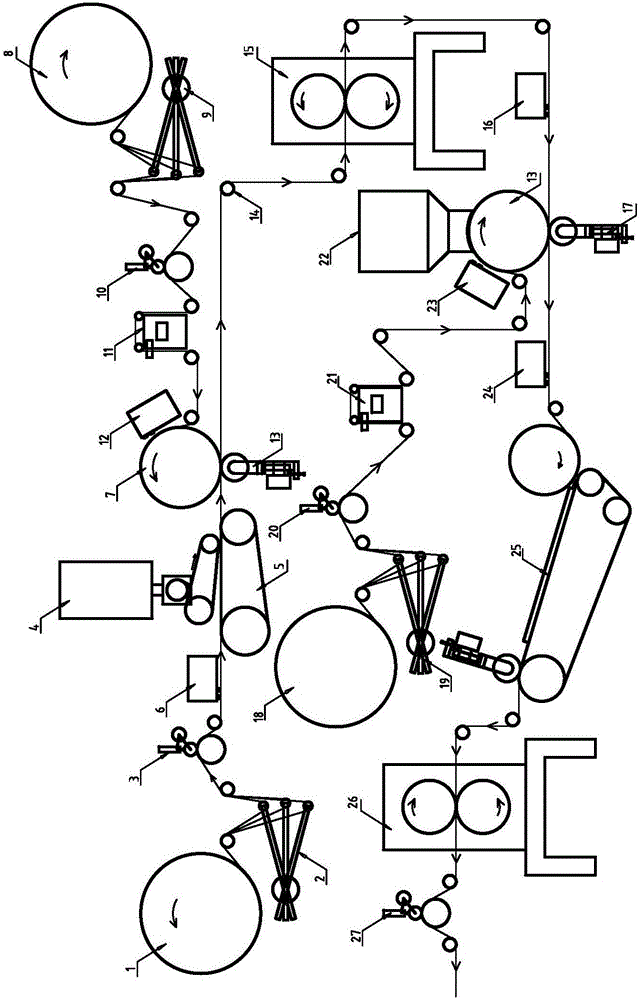

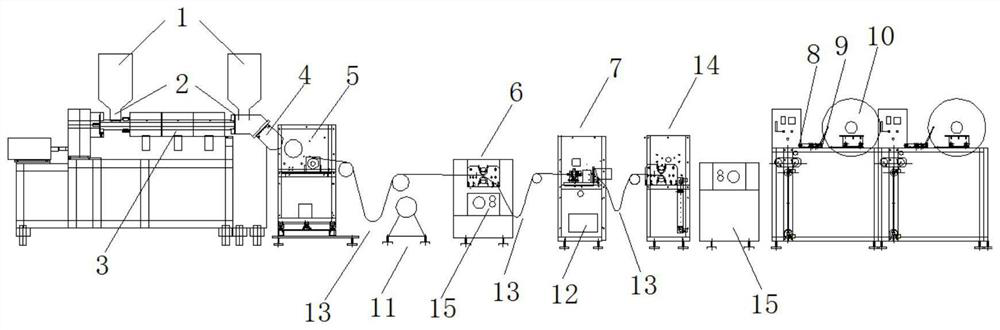

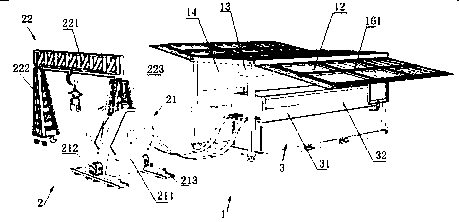

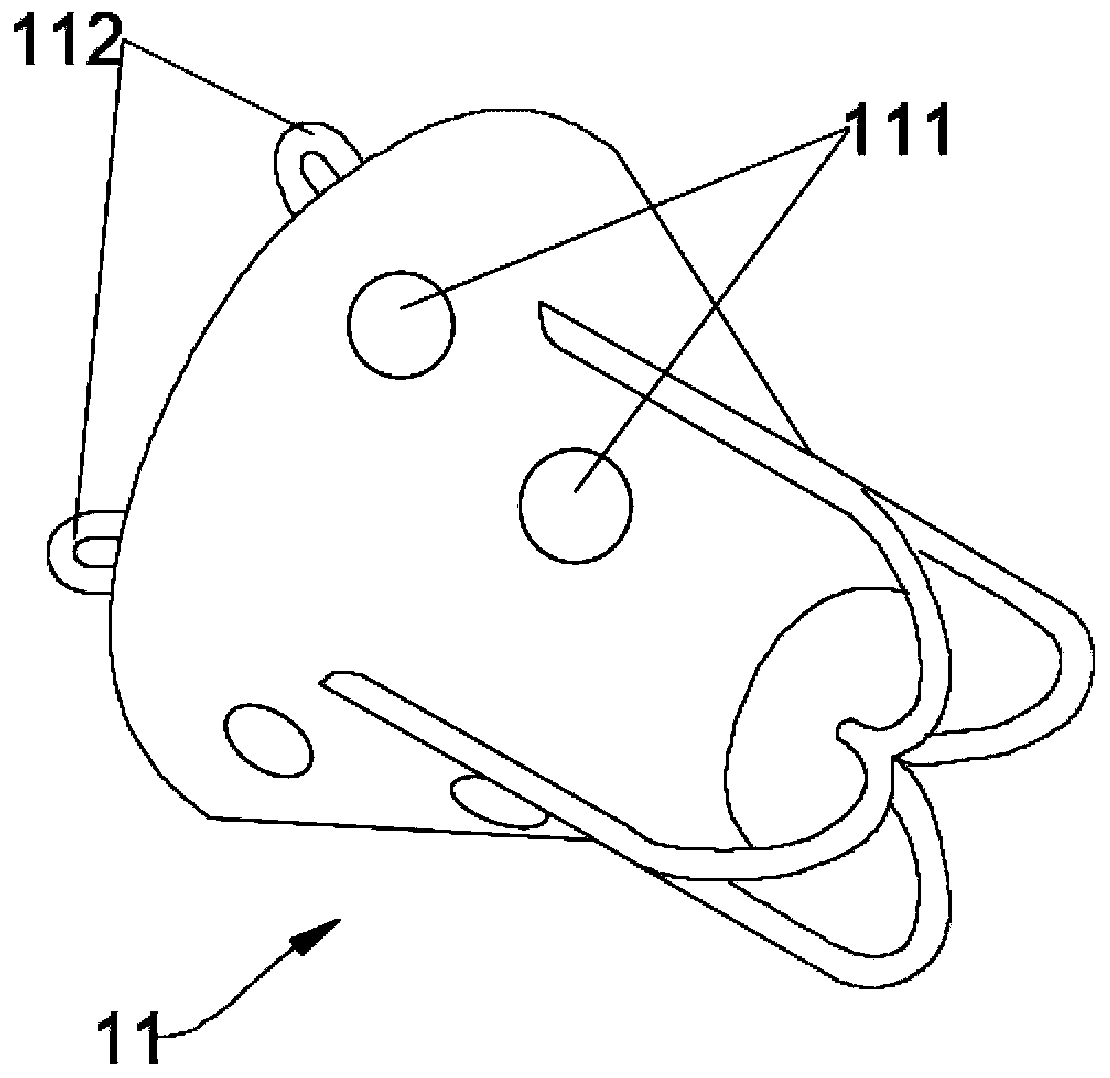

Cotton core forming process

InactiveCN107174407AStable absorption effect is goodIncrease contentAbsorbent padsBaby linensProduction lineMetallurgy

The invention relates to the field of manufacturing of sanitation supplies and provides a cotton core forming process. The process comprises the following steps: (1) applying a composite polymer layer to the lower surface of an intermediate fluffy non-woven fabric layer and feeding the composite polymer layer to a material transfer composite roller; (2) conveying a bottom fluffy non-woven fabric, performing edge correction, spraying glue, and feeding to the material transfer composite roller; (3) gluing the composite intermediate fluffy non-woven fabric layer and the upper surface of the intermediate fluffy non-woven fabric of the composite bottom fluffy non-woven fabric layer, and feeding to a second firm pressing mechanism; (4) performing massive discontinuous glue spraying on the upper fluffy non-woven fabric, discontinuously arranging the polymer layer and fixedly laminating with the intermediate fluffy non-woven fabric and the bottom fluffy non-woven fabric, and completing compounding of the three layers; and (5) folding, covering, compacting and reinforcing excessive parts of the bottom fluffy non-woven fabric compared with two sides of the intermediate fluffy non-woven fabric and the upper non-woven fabric, thereby obtaining the formed cotton core. According to the process disclosed by the invention, the problems that the conventional cotton core is high in forming cost, complicated in process and long in production line are solved.

Owner:QUANZHOU HANWEI MACHINERY MFG

Cylinder sleeve cutting equipment capable of achieving scrap suction conveniently

InactiveCN107414165AEasy to cleanAvoid damageShearing machinesMaintainance and safety accessoriesHydraulic cylinderEngineering

The invention discloses cylinder sleeve cutting equipment capable of achieving scrap suction conveniently. The cylinder sleeve cutting equipment capable of achieving scrap suction conveniently comprises a cutting table, and the cutting table is formed through plain warp-weft weaving of steel wires. A blocking plate is arranged on one side of the cutting table and located on the feeding stroke of a cylinder sleeve. The blocking plate is connected with the movable end of a third hydraulic cylinder in a driven mode and driven by the third hydraulic cylinder to move horizontally, and the moving direction of the blocking plate is parallel to the feeding direction of the cylinder sleeve. A pushing plate is arranged on the other side of the cutting table. The pushing plate is connected with the movable end of a seventh hydraulic cylinder in a driven mode and driven by the seventh hydraulic cylinder to move horizontally, and the moving direction of the pushing plate is perpendicular to the feeding direction of the cylinder sleeve. A scrap suction device comprises a scrap suction pipe, a scrap collection box and a draught fan, wherein a feeding port of the scrap suction pipe is located below the cutting table, a discharging port of the scrap suction pipe communicates with the scrap suction box, and the draught fan is located on one side of the scrap suction box. According to the cylinder sleeve cutting equipment capable of achieving scrap suction conveniently, waste scraps generated in the cutting process can be removed, the labor intensity is low, the machining time is short, and the machining efficiency is high.

Owner:ZYNP GRP ANHUI CO LTD

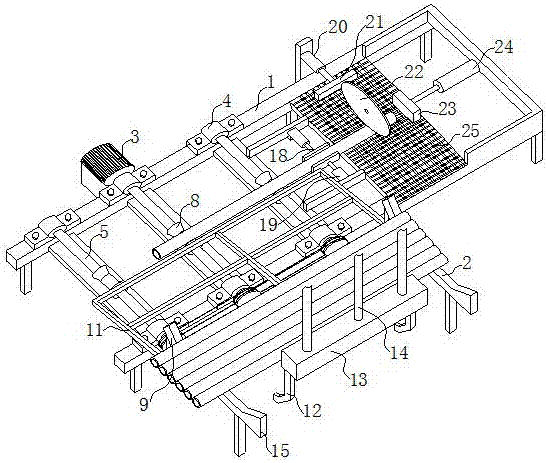

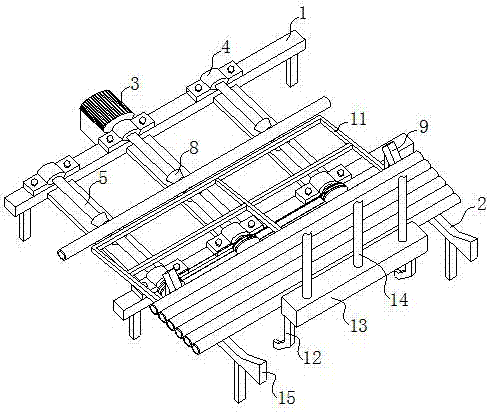

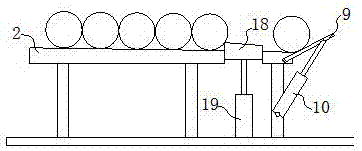

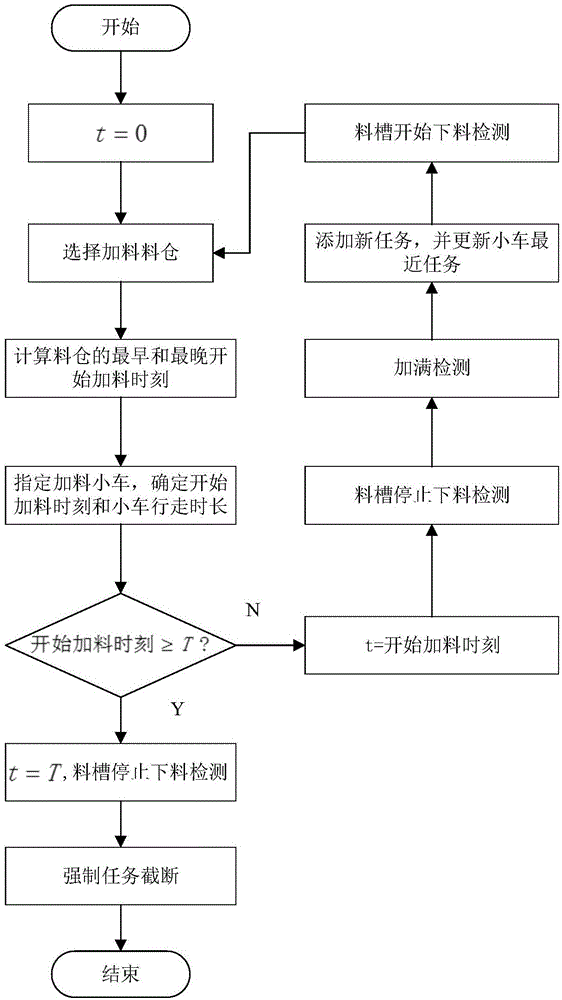

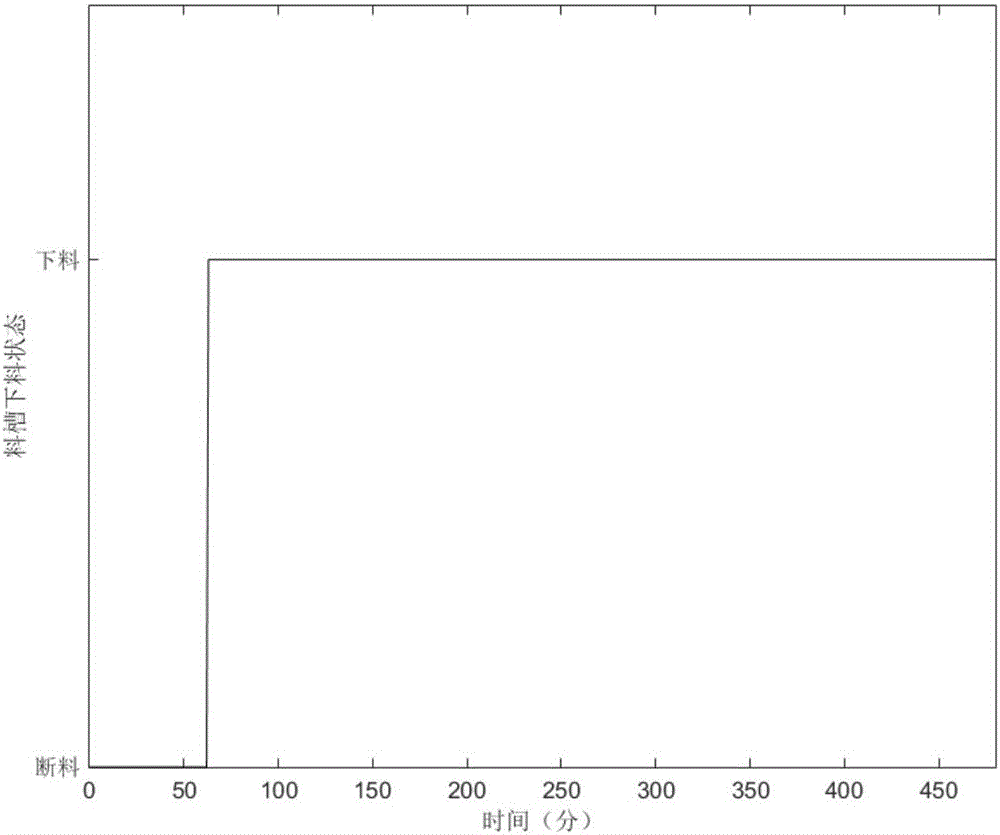

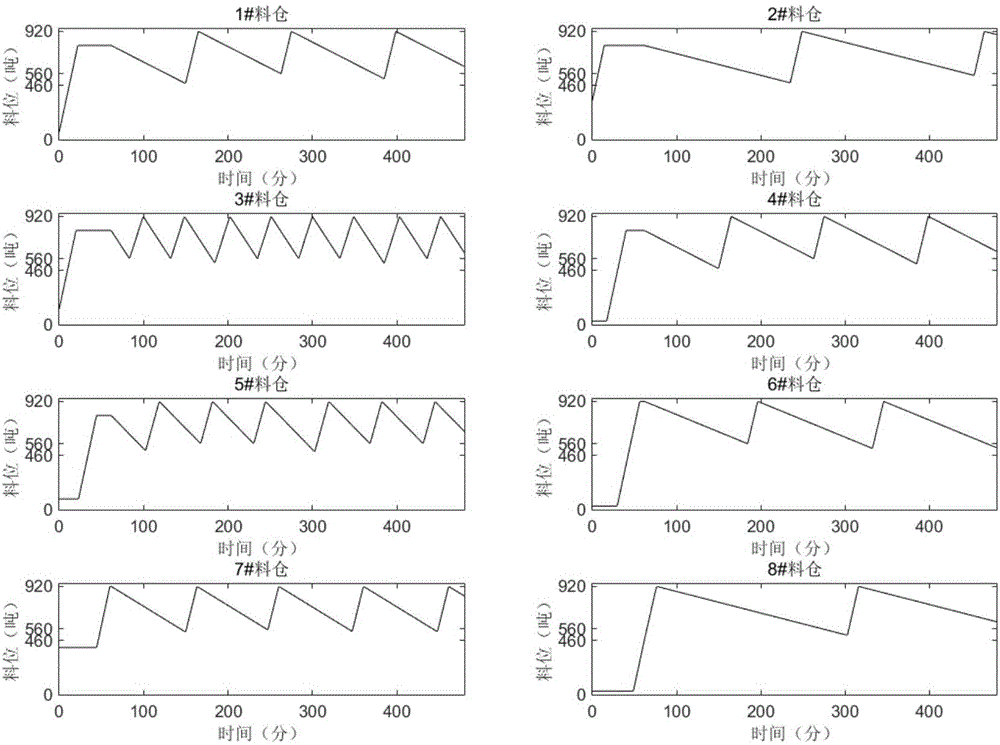

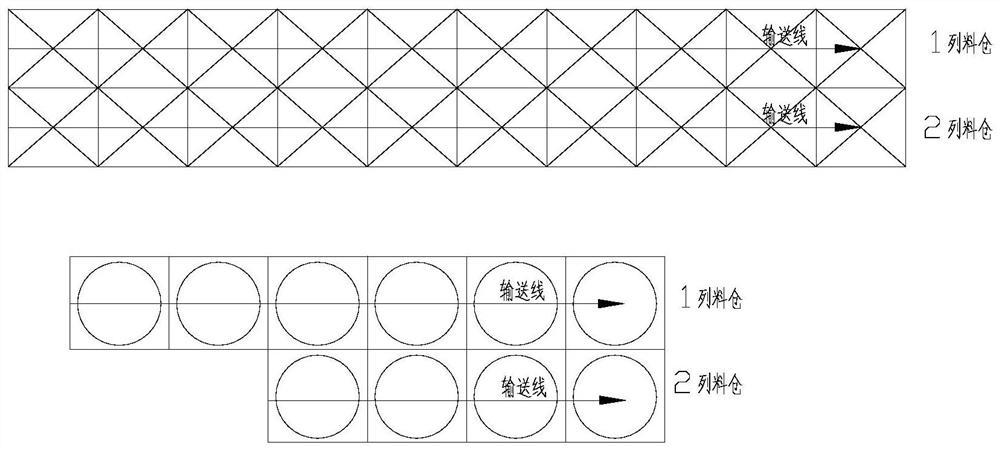

Automatic compiling method for charging time sequence of continuous batching bin

ActiveCN106327096ASolve the problem of timing control of feedingAvoid material breakResourcesLoading/unloadingMixing effectComputer science

The invention discloses an automatic compiling method for a charging time sequence of a continuous batching bin, and the method comprises the following steps: collecting related parameters of a feed trough, and enabling the related parameters to serve as the known conditions of the time sequence control; obtaining various types of initial state information at a starting moment and the feed trough operation information required by a uniform mixing task; and pushing a clock to compile the charging time sequence of the continuous batching bin according to an enlightening rule through employing bin charging demands. Because the bin charging demands are discrete, an interruption-like effect can be generated through employing the bin charging demands to push the clock, and the mode of pushing the clock through employing the bin charging demands is different from a mode of pushing the clock at a fixed step, thereby avoiding the unnecessary inquiry and calculation, and improving the performance of the compiling of the charging time sequence of the continuous batching bin. The method can solve a problem of charging time sequence control of all bins in a uniform mixing feed trough in a production process of a uniform fixing stock ground, and avoids the unnecessary interruption of the charging of the uniform mixing feed trough. The method can improve the production efficiency and uniform mixing effect of the uniform mixing feed trough.

Owner:WISDRI ENG & RES INC LTD

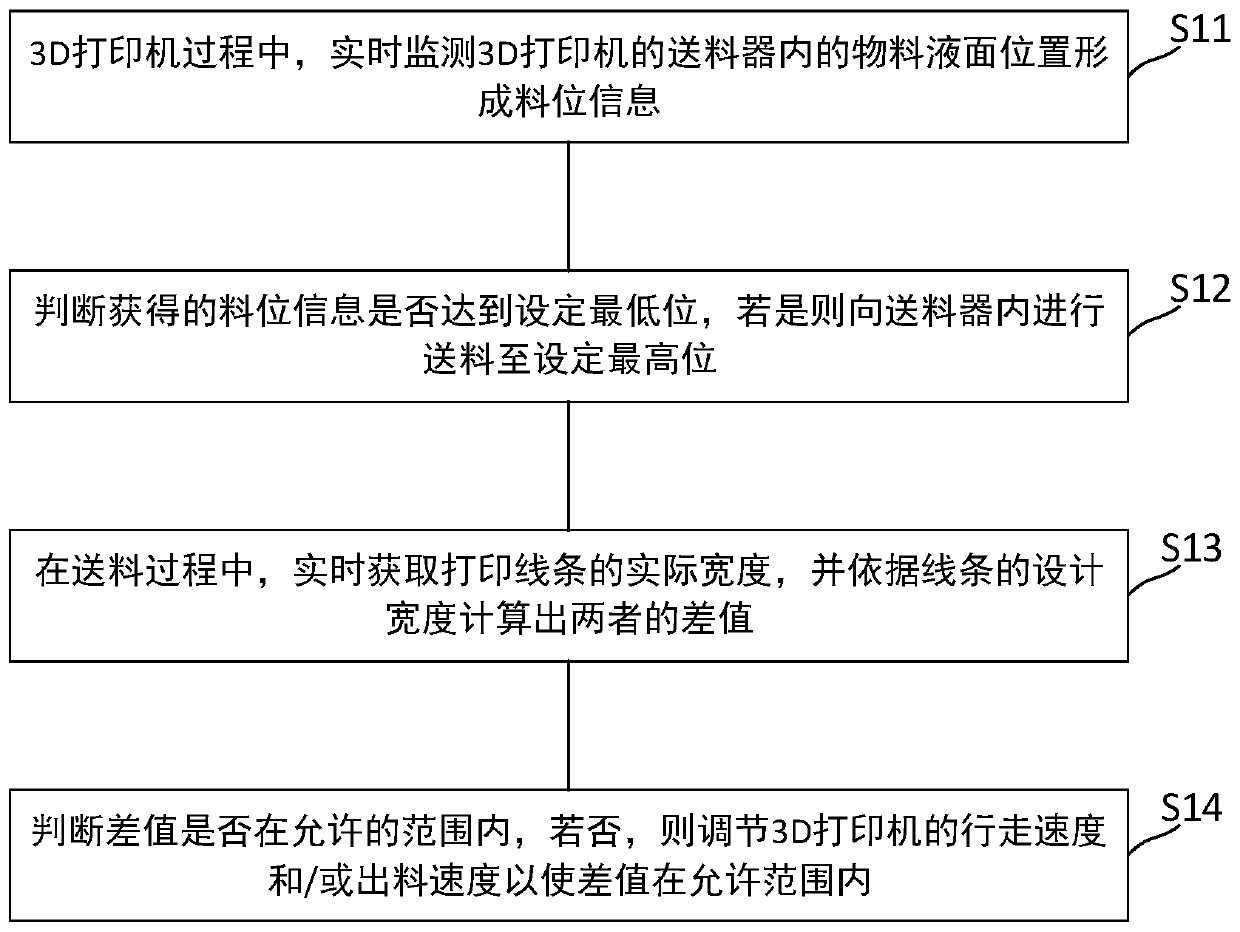

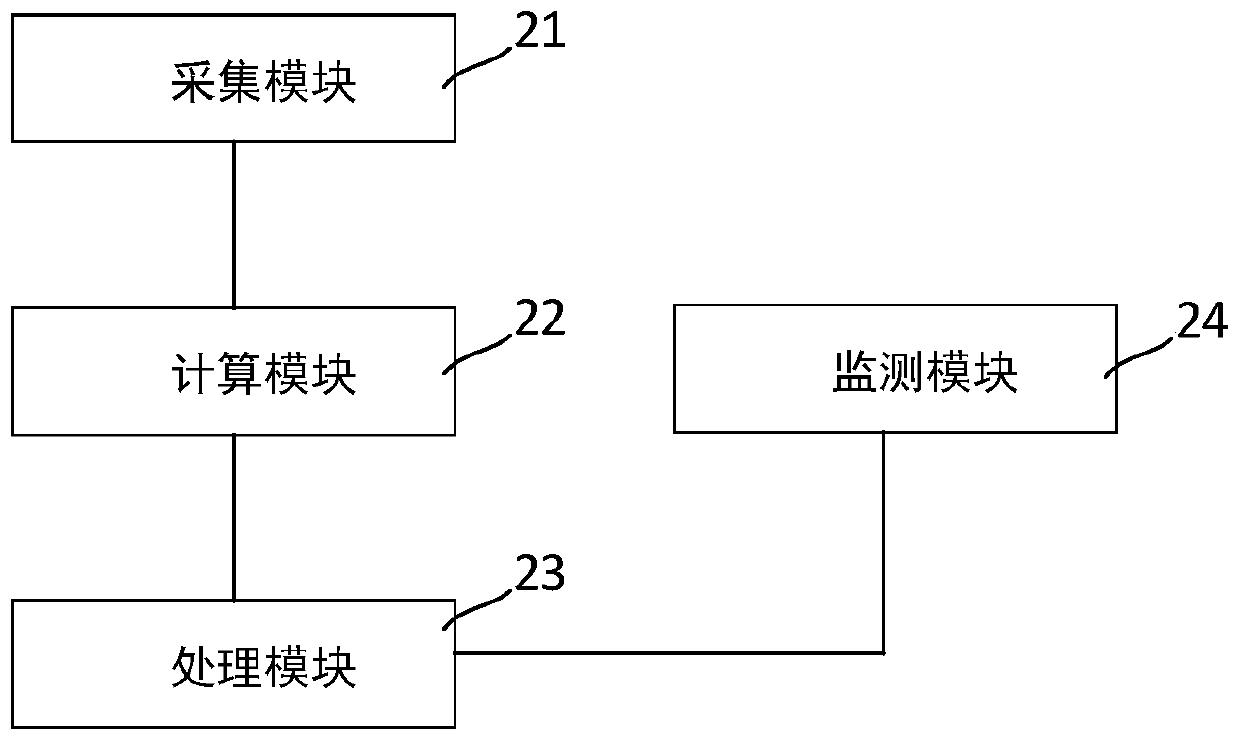

Building 3D printing circulating feeding control method and system

ActiveCN110281346AReal-time monitoring of actual widthHigh precisionAdditive manufacturing apparatusCeramic shaping apparatus3d printerConstruction 3D printing

The invention relates to a building 3D printing circulating feeding control method and system. The method comprises the following steps of in the 3D printing process, monitoring in real time the material liquid level position in a feeding device of a 3D printer and forming material level information; judging whether the obtained material level information reaches the set lowest position or not, and if yes, feeding material to the feeding device until the material level information reaches the set highest position; in the feeding process, acquiring in real time the actual width of printing lines, and calculating the difference value between the actual width of the obtained printing lines and the designed width of the lines according to the designed width of the lines; and judging whether the calculated difference value is within an allowable range or not, and if not, adjusting the travelling speed and / or the discharging speed of the 3D printer so as to enable the difference value to be within the allowable range. According to the control method, real-time detecting, real-time printing and real-time adjusting are realized, so that the quality of 3D printing can be improved by the feedback, and the precision of components formed by printing is improved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

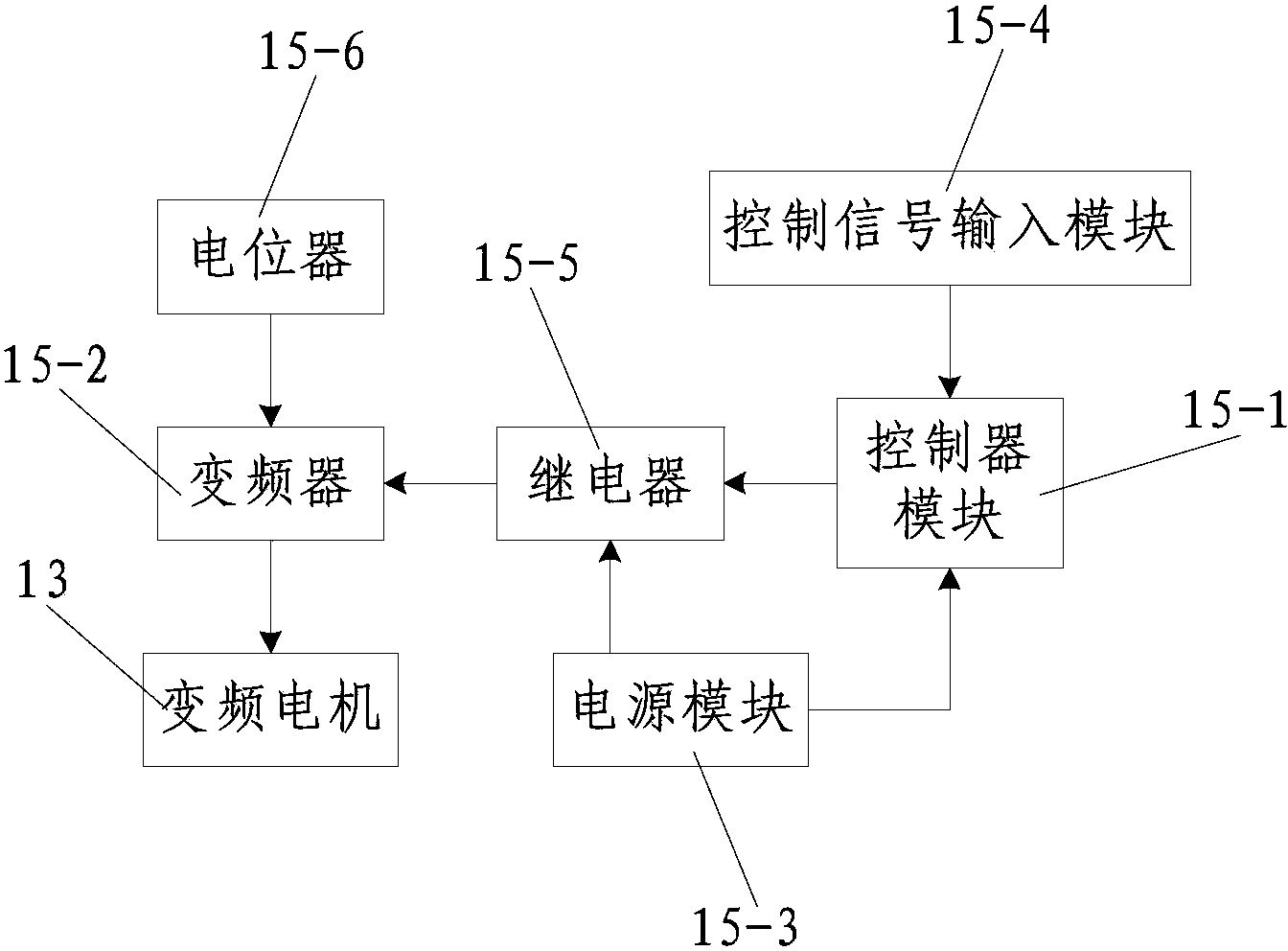

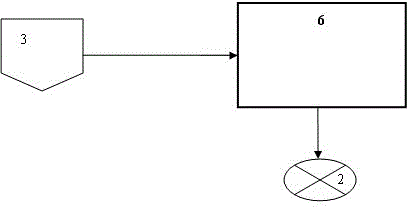

Tobacco shred material flow control device and method

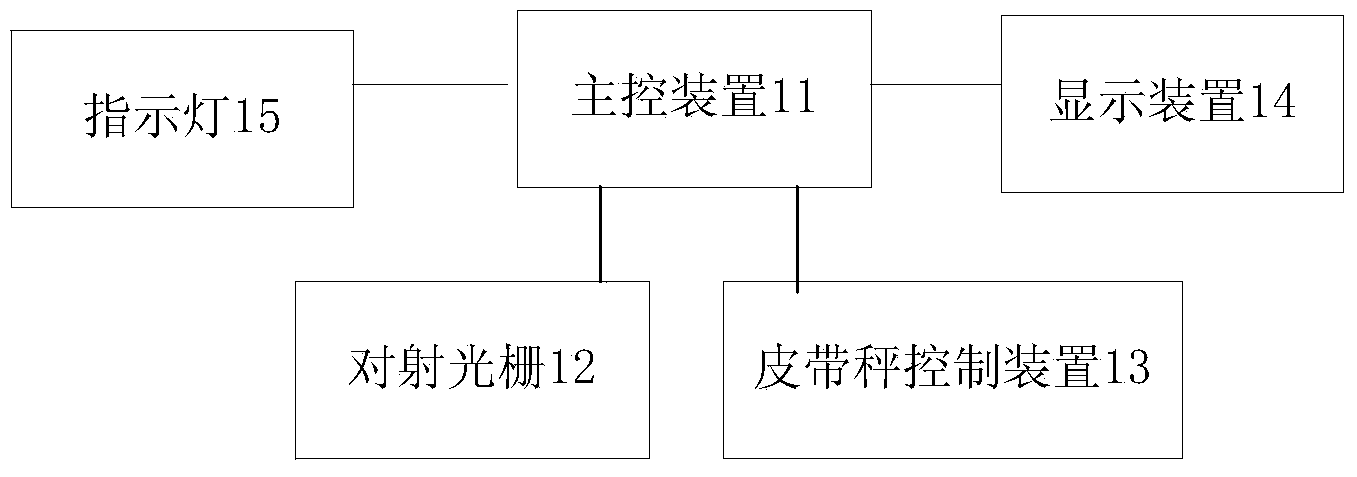

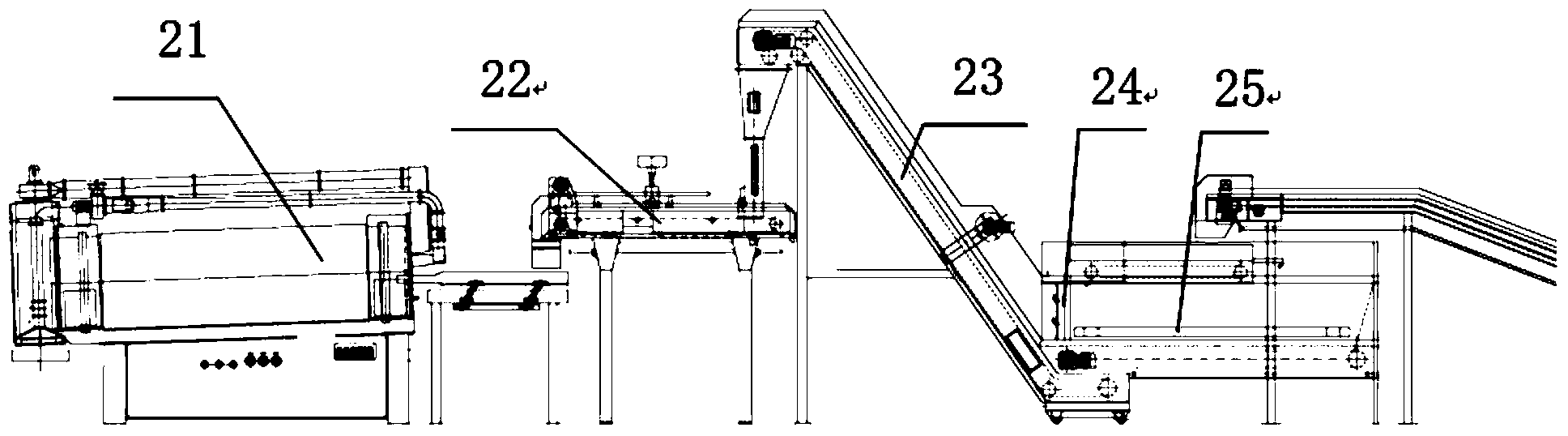

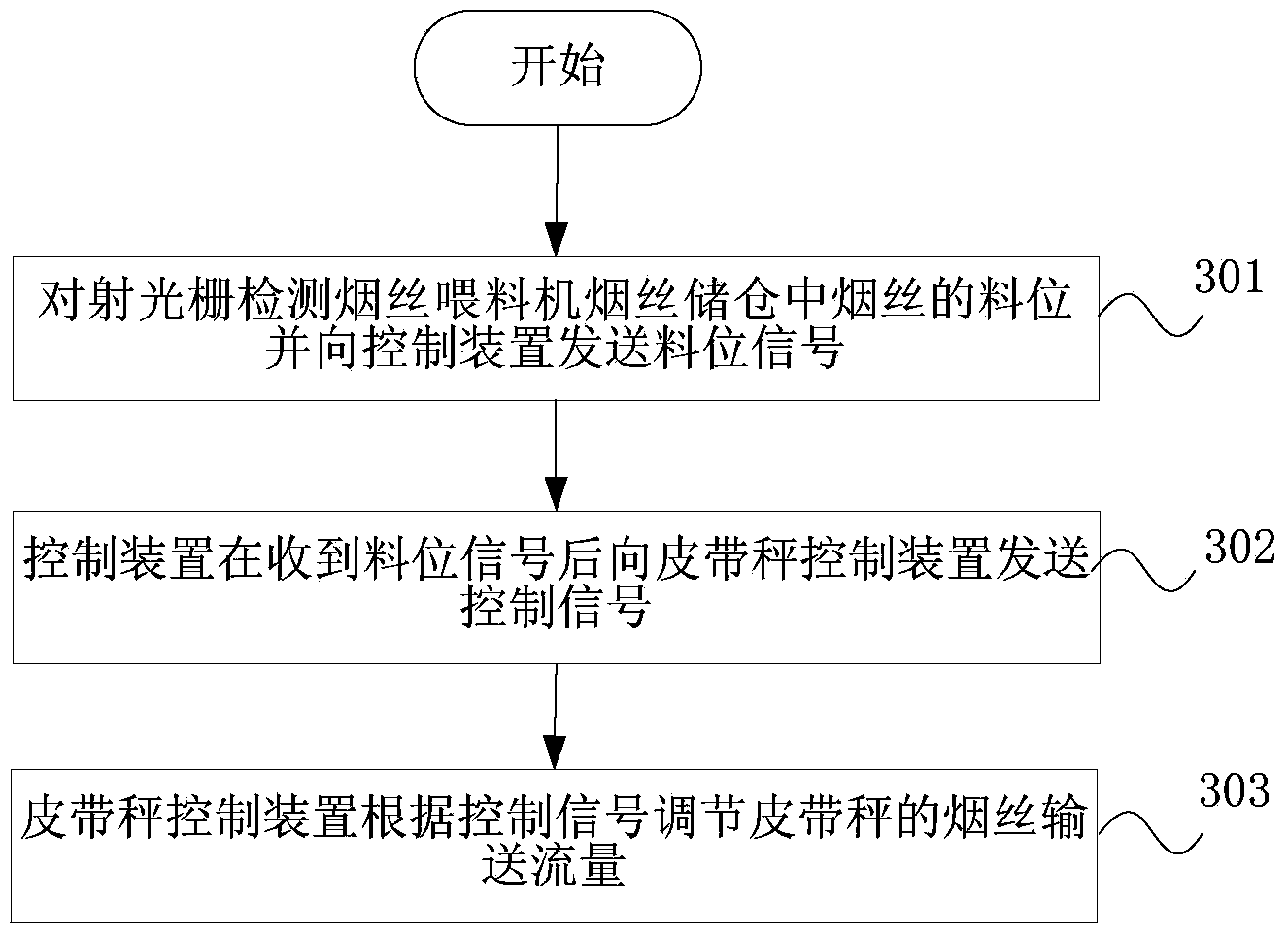

ActiveCN103744441AAvoid material breakGuaranteed continuityFlow control using electric meansElectricityEngineering

The invention discloses a tobacco shred material flow control device and a tobacco shred material flow control method. The tobacco shred material flow control device comprises a bijection optical grating, a main control device and a belt weigher control device, wherein the main control device is respectively and electrically connected with the bijection optical grating and the belt weigher control device, the inner wall of a tobacco shred feeding machine storage bin is provided with the bijection optical grating which is used for detecting the material positions of tobacco shreds in the tobacco shred feeding machine storage bin and sending material position signals to the main control device, the main control device sends a control signal to the belt weigher control device, and the belt weigher control device controls the tobacco shred conveying flow. The tobacco shred material flow control device and the tobacco shred material flow control method can be used for adjusting the tobacco shred flow of a belt weigher according to the material positions detected by the bijection optical grating, so that the feeding machine storage bin can be kept in a stable material position under the condition of ensuring the relatively stable perfuming flow, accordingly the condition that materials are broken is effectively avoided, and the continuity of production is ensured.

Owner:LONGYAN CIGARETTE FACTORY

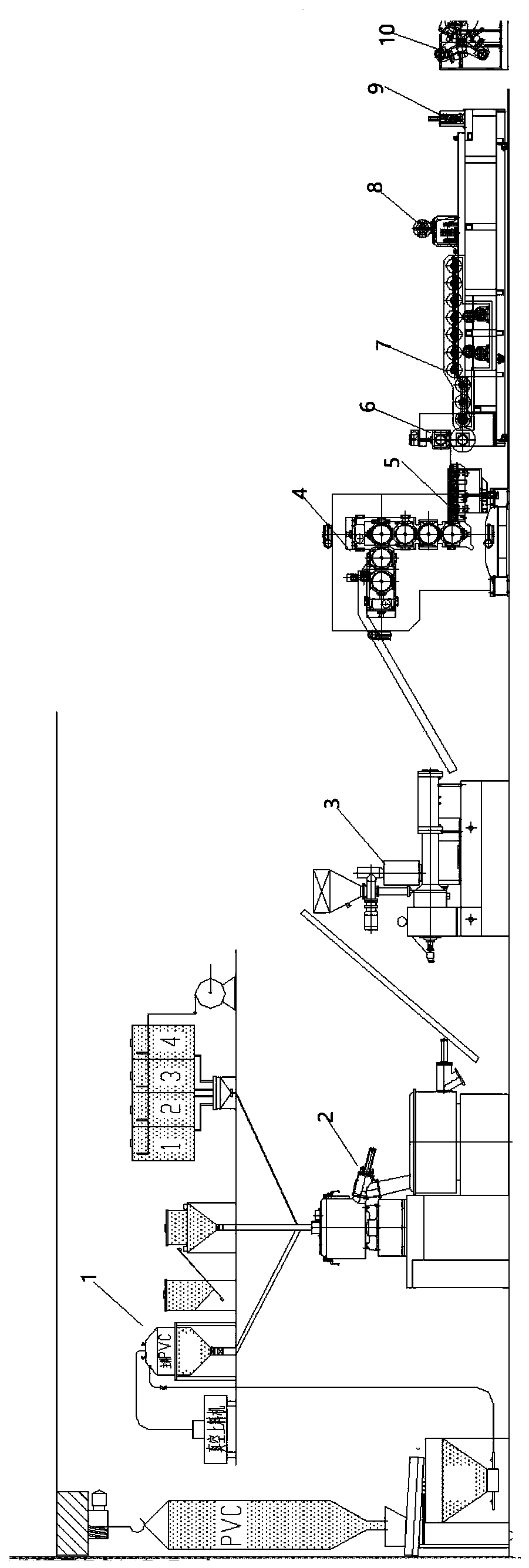

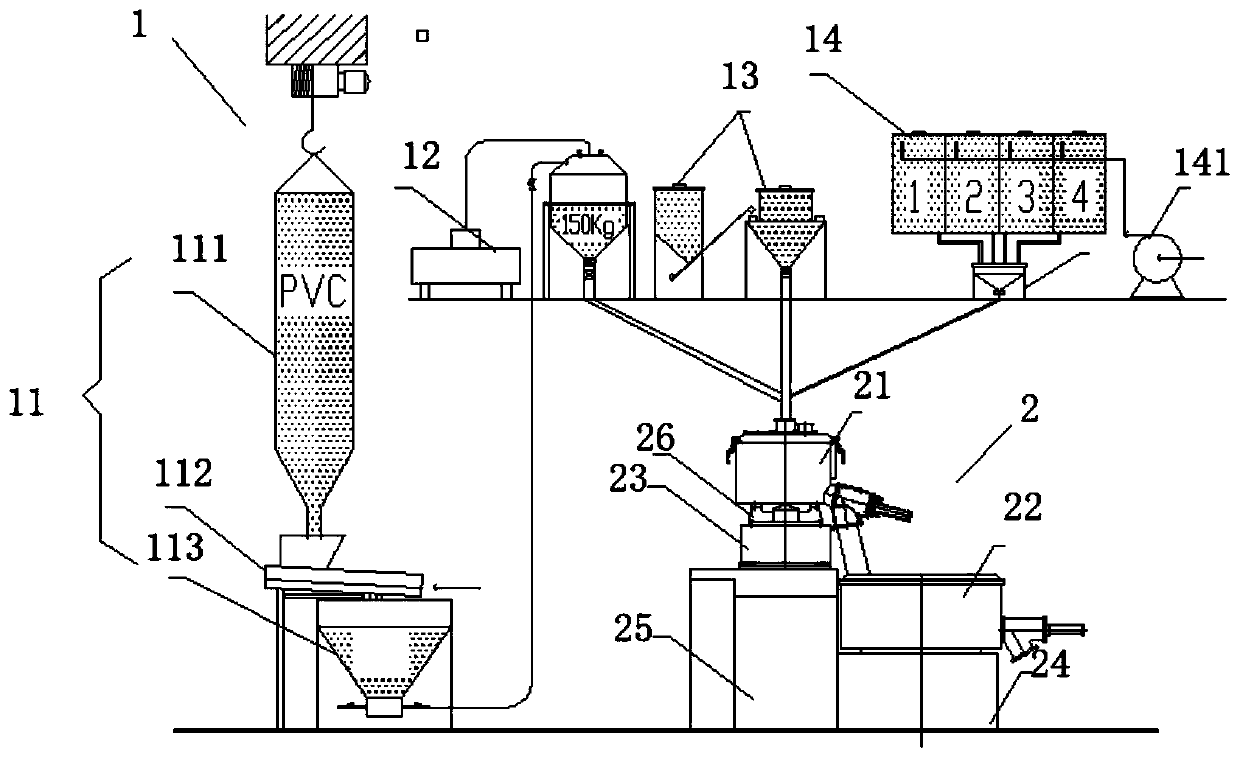

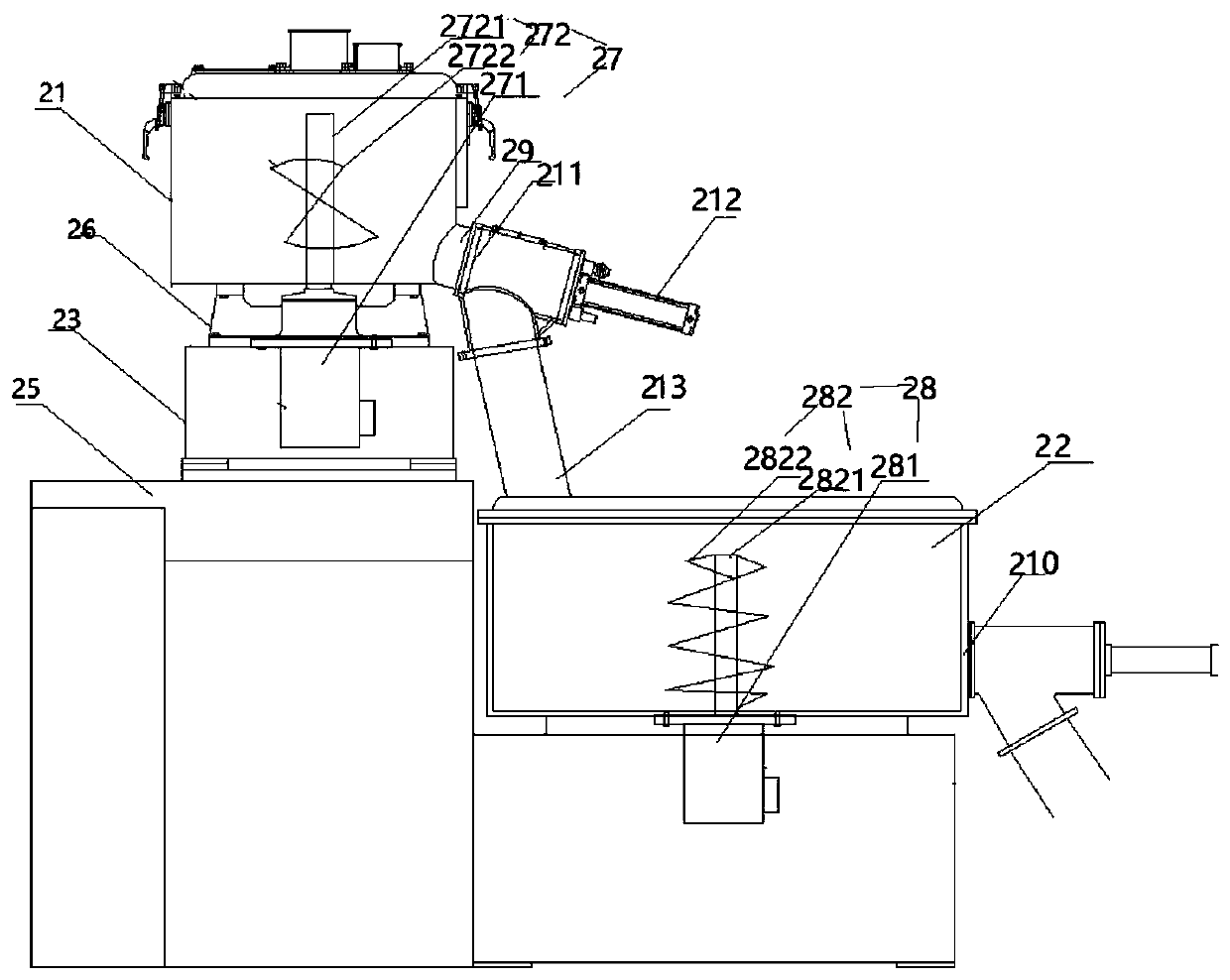

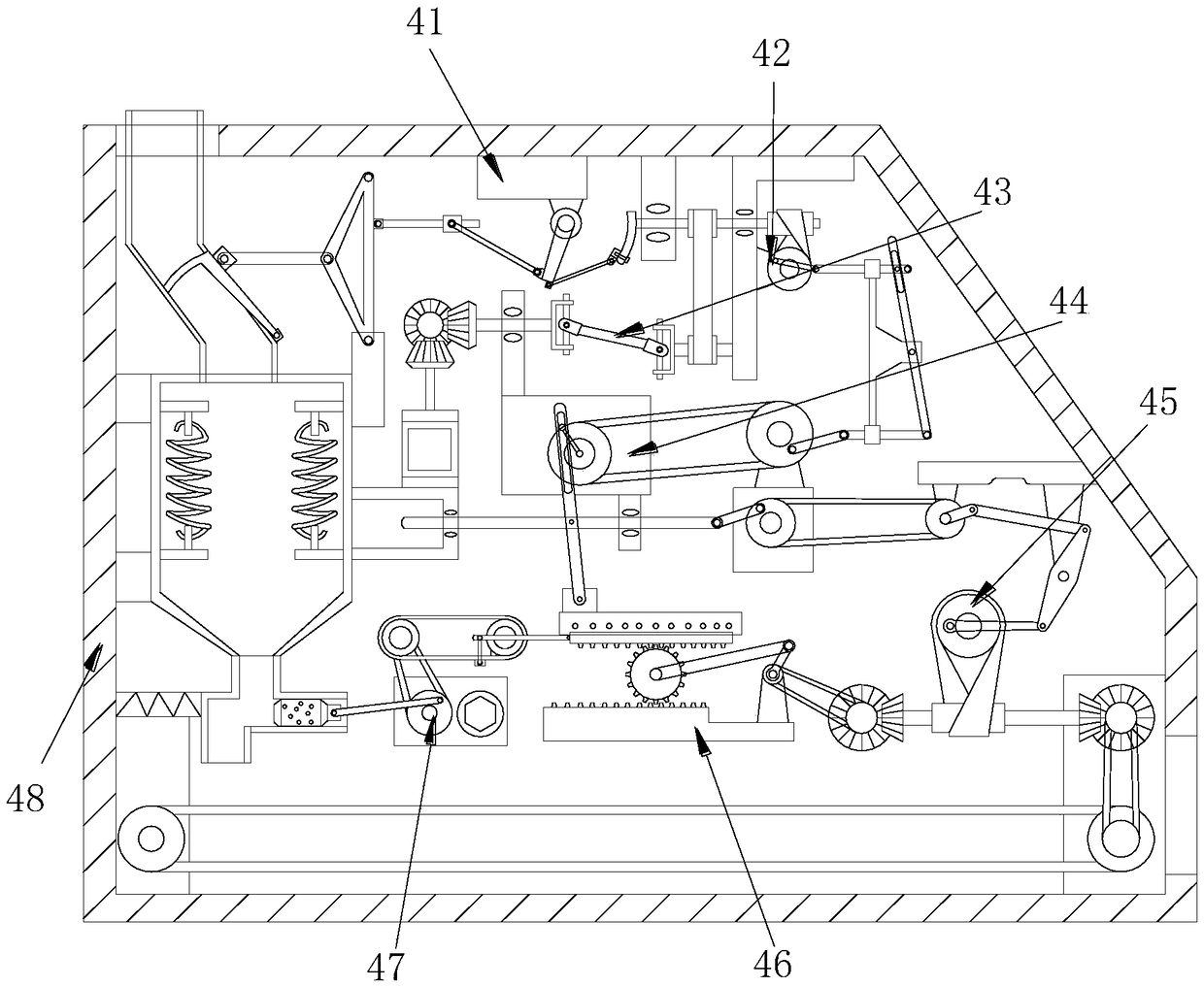

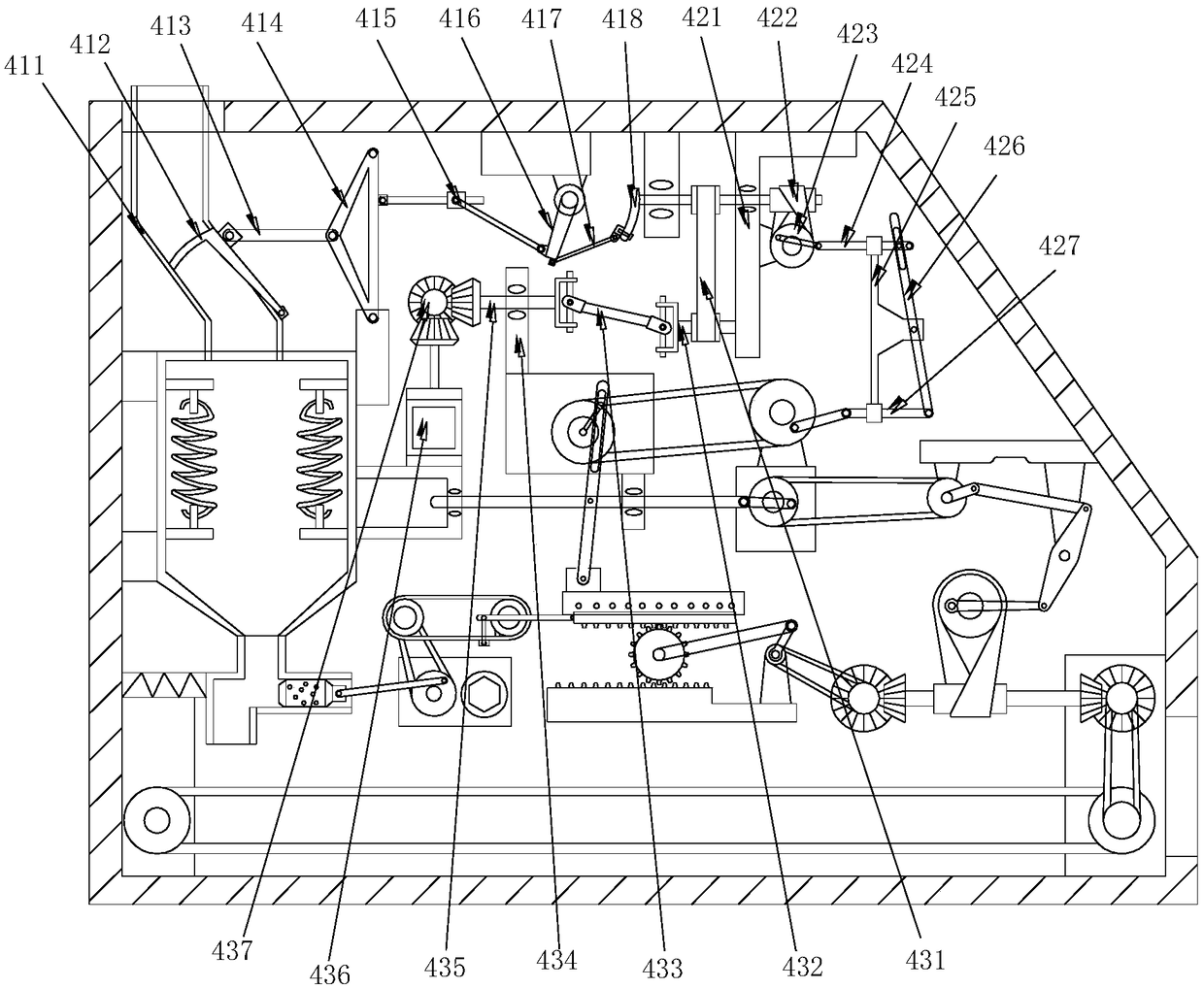

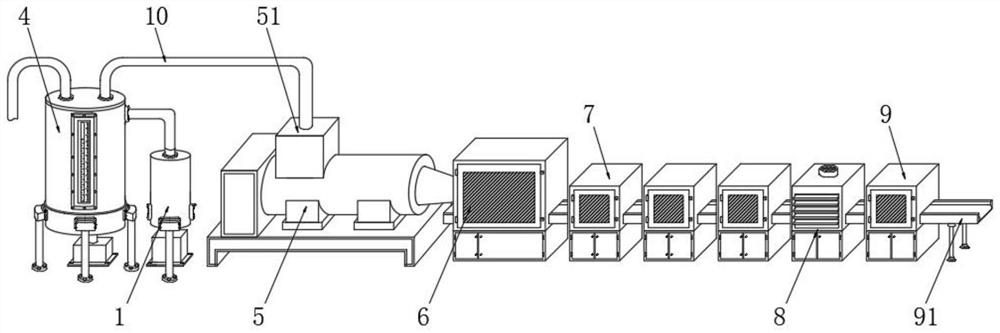

Efficient automatic production line for PVC processing and working method of efficient automatic production line

PendingCN111098467ASimple structureReasonable designFlat articlesProduct processingProcess engineering

The invention discloses an efficient automatic production line for PVC processing. The efficient automatic production line comprises an automatic feeding mechanism, a mixing mechanism, a planetary extruder, a six-roll calendaring primary and auxiliary machine, a roll stripping mechanism, a calender roll, a roll cooling mechanism, an offcut removing mechanism, a traction roll and a sheet coiler, araw material storage device, a vacuum feeding machine and a group of auxiliary material storage devices and a group of processing auxiliary tanks are arranged in the automatic feeding mechanism, a discharging opening of the mixing mechanism is connected with a feeding opening of the planetary extruder through a feeding pipe, a discharging opening of the planetary extruder is connected with the six-roll calendaring primary and auxiliary machine through a transmission belt, and the roll stripping mechanism, the calender roll, the roll cooling mechanism, the offcut removing mechanism, the traction roll and the sheet coiler are sequentially arranged on the rear portion of the six-roll calendaring primary and auxiliary machine. The efficient automatic production line is simple in structure, reliable in design and easy to operate, the automation from raw material processing to finished product coiling is achieved thoroughly, the product processing quality is improved, and the PVC film production efficiency is also improved.

Owner:苏州锐驰朗新材料有限公司

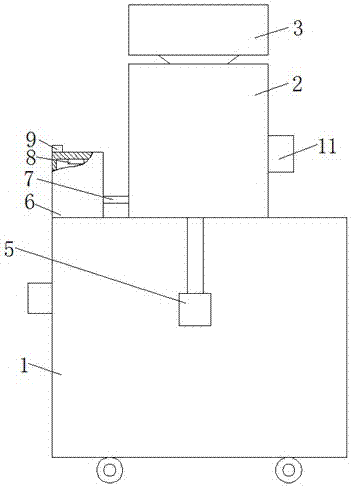

Rubbish smashing device for environment protection

InactiveCN110756258AEasy automatic maintenanceAvoid material breakCleaning using toolsGrain treatmentsMaterial supplyIndustrial engineering

The invention relates to the rubbish smashing technology field, in particular to a rubbish smashing device for environment protection. The rubbish smashing device for the environment protection comprises a support seat, wherein a discharging device is arranged on the left side of the top end of the support seat, a smashing box is arranged on the right side of the discharging device, the smashing box is fixedly connected with the support seat, a smashing roller is rotatably connected with the top end of the inner side of the smashing box, a loading device is fixedly connected with the right side face of the support seat, and the loading device is fixedly connected with the smashing box. By adopting the arrangement mode of arranging a push plate, a second conveying machine and a draught fanand using the arrangement mode cooperatively with slip connection between a cam and the push plate, rotating connection between the push plate and a support frame, fixed connection between the secondconveying machine and the support frame and air drying of the draught fan for the second conveying machine, after the device is started, a fixed amount of damp rubbish is first placed in the support frame, then automatic loading of the rubbish is performed, and therefore a material supply failure phenomenon is prevented from occurring, and labor cost is reduced, and furthermore automatic maintenance for a rubbish conveying mechanism is facilitated, and use life of the device is prolonged.

Owner:白保平

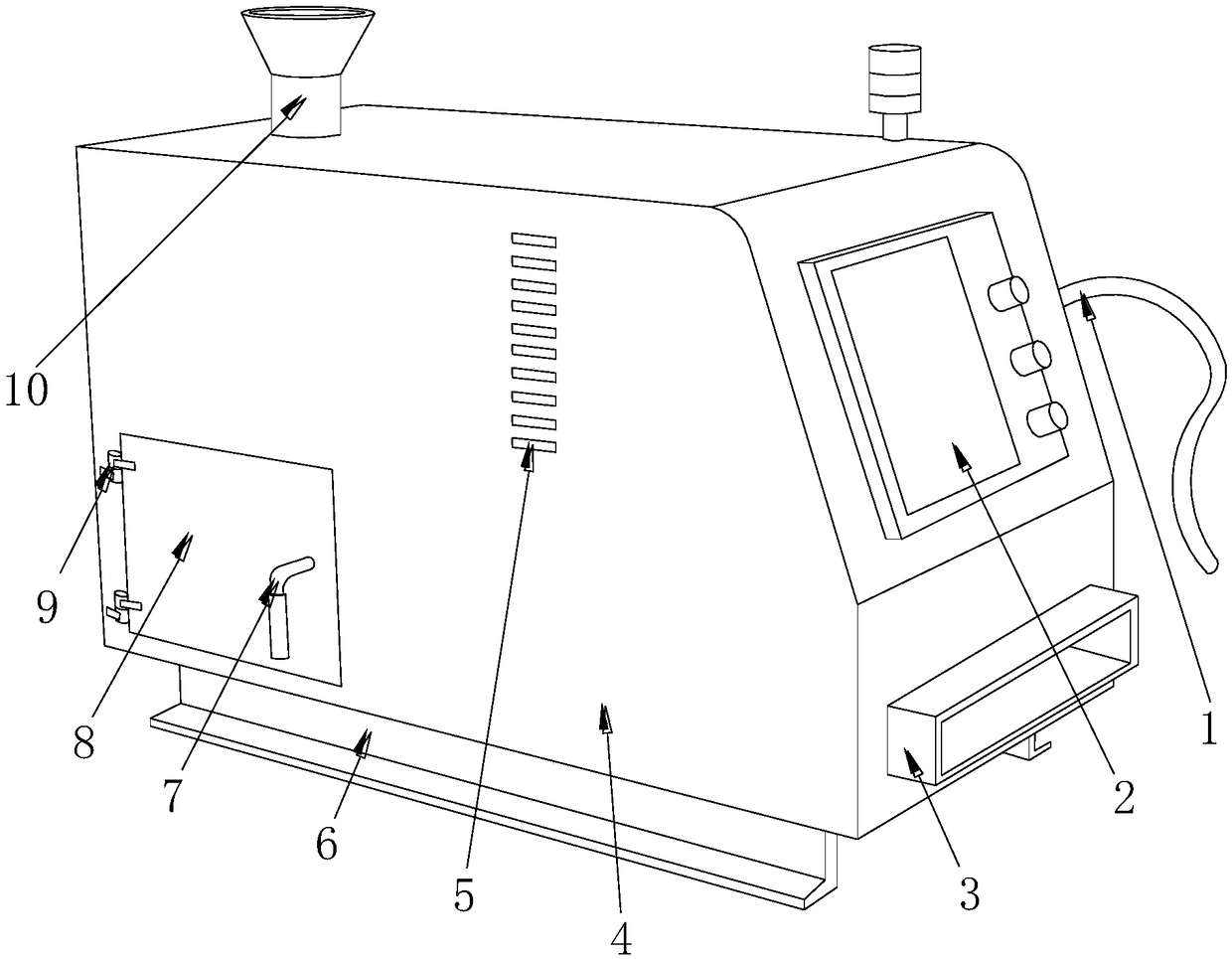

Device for supplying unmelted hot melt adhesive pieces

InactiveCN108855786AShorten melting timeAvoid material breakLiquid surface applicatorsCoatingsThermal insulationHot melt

The invention discloses a device for supplying unmelted hot melt adhesive pieces. The structure of the device comprises a power cord, a control panel, a feedwell, a preheating thermal insulation device, an air vent, a steel backing plate, a handle, an opening and closing door, a plug pin, and a feeding funnel, wherein the feeding funnel is embedded in the left end of the upper surface of the preheating thermal insulation device, the steel backing plate is welded with the lower end of the preheating thermal insulation device, the air vent is embedded in the upper end of the front side of the preheating thermal insulation device, the plug pin is welded with the left end of the opening and closing door, and the opening and closing door is hinged to the left end of the front side of the preheating thermal insulation device by the plug pin. The device for supplying unmelted hot melt adhesive pieces heats the hot melt adhesive pieces firstly through the preheating thermal insulation device when supplying the hot melt adhesive pieces to make the temperature of the hot melt adhesive pieces between the freezing point and the melting point, so that the hot melt adhesive pieces can quickly reach the melting point temperature when entering a melting box of a hot melt adhesive machine, thereby shortening the melting time of the hot melt adhesive pieces, improving the hot melt efficiency, ensuring the adhesive supply speed, and avoiding feeding interruption of the hot melt adhesive machine during the adhesive application.

Owner:芜湖启邦电力技术服务有限公司

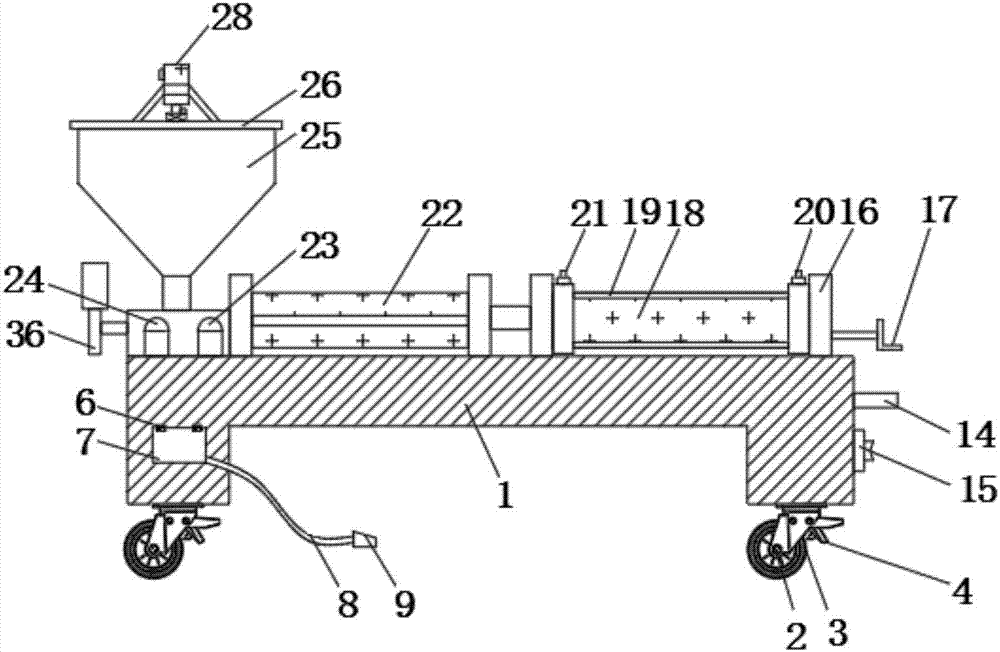

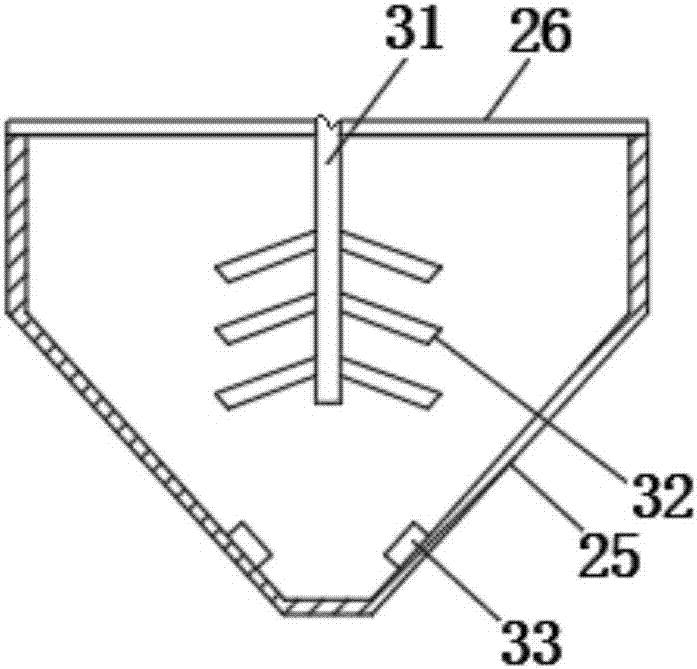

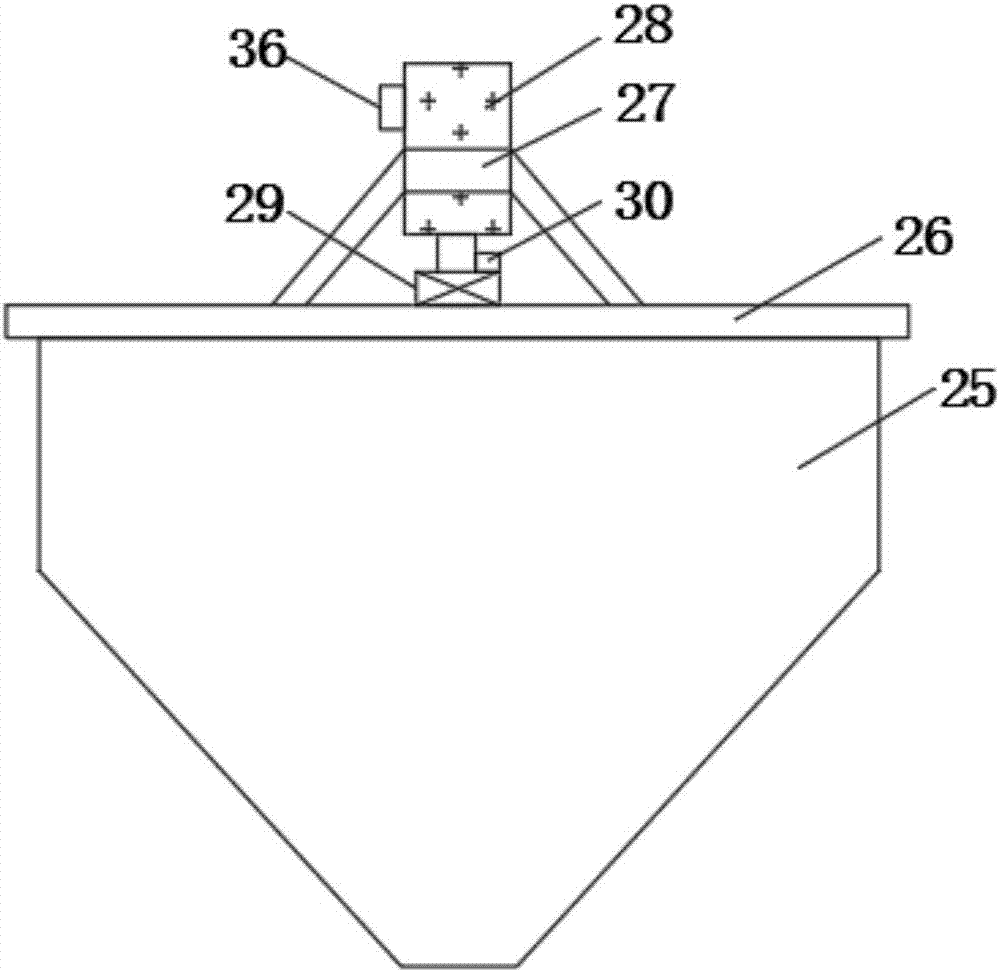

Pneumatic paste filling machine

InactiveCN107323707APrevent precipitationAvoid condensationPackaging automatic controlLiquid materialCouplingProgrammable logic controller

The invention discloses a pneumatic paste filling machine. The machine comprises a base and a storage hopper; sliding wheels are mounted at the bottom of the base through fixing rotating shafts; a brake rod is mounted on one side of each sliding wheel; an accommodating groove is formed in one side of the base; a sealing cover is mounted at one end of the accommodating groove through first hinges; a power switch is mounted on one side of an air inlet; a second alarm is mounted on one side of a first alarm; the storage hopper is mounted on one side of the second alarm; a stirring motor is mounted in the middle of a motor frame; a programmable logic controller (PLC) is mounted on one side of the stirring motor; a rotating shaft is sleeved with the other side of a coupling; stirring blades are welded at the bottom of the rotating shaft; and a pressure sensor is mounted at the bottom end inside the storage hopper. The machine is convenient to move, paste sedimentation or condensation can be prevented, the product quality can be improved, a foot switch is convenient to store, the storage hopper is monitored in real time, material breakage is prevented, and the machine is convenient to use.

Owner:FOSHAN HANGESI ENVIRONMENTAL PROTECTION TECH CO LTD

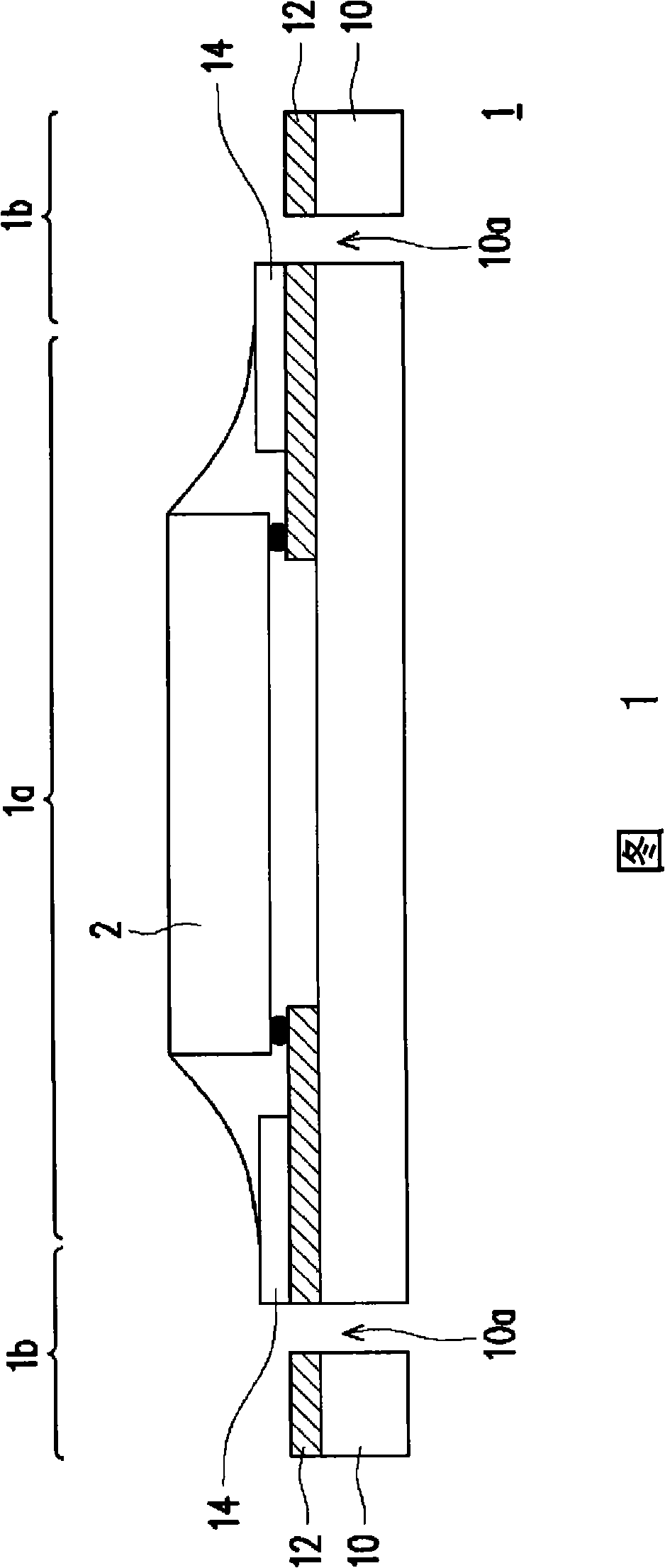

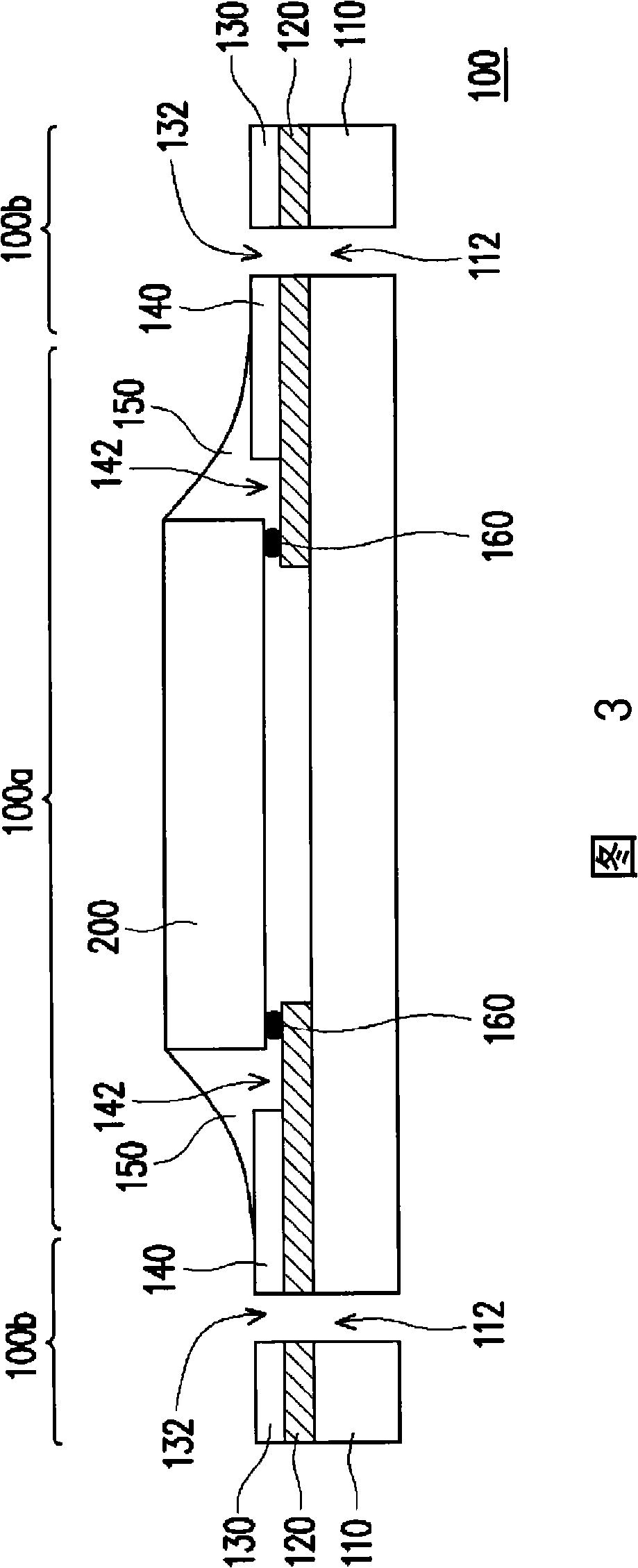

Flexible circuit board

InactiveCN101281896AExcellent process cleanlinessHigh tensile strengthPrinted circuit detailsSemiconductor/solid-state device detailsFlexible circuitsDielectric layer

A flexible circuit board has a encapsulation region and a transmission region arranged at two opposite sides of the encapsulation region. The flexible circuit board includes a flexible base material, a patterned metal layer and a dielectric layer. The flexible base material has a plurality of holes which arranged in the transmission region. The patterned metal layer is equipped on the flexible base material, at least covers the flexible base material in the transmission region and exposes the transmission holes. The dielectric layer covers the patterned metal layer in the transmission layer and exposes the transmission holes.

Owner:AU OPTRONICS CORP

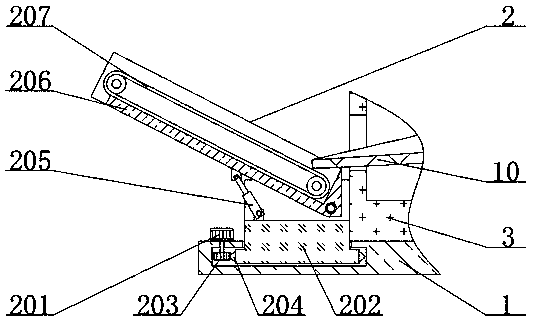

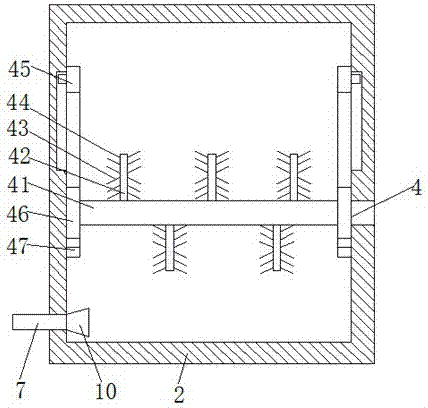

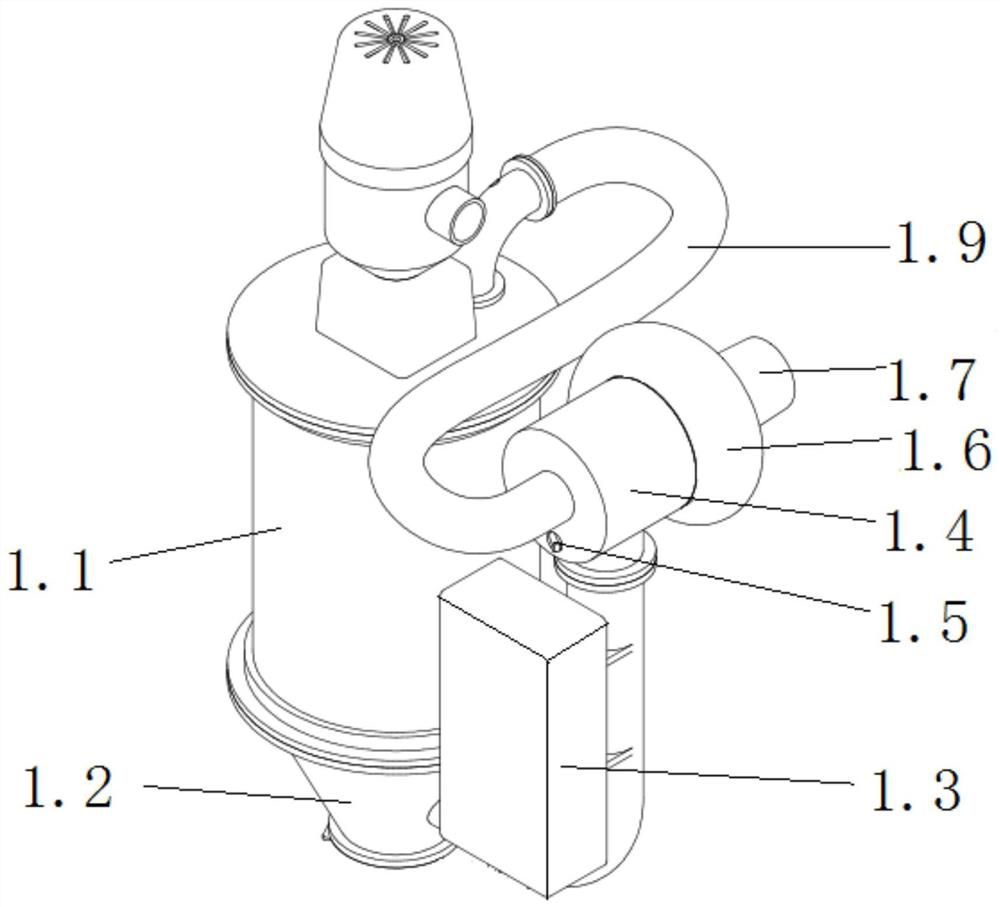

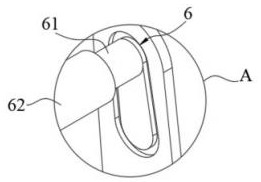

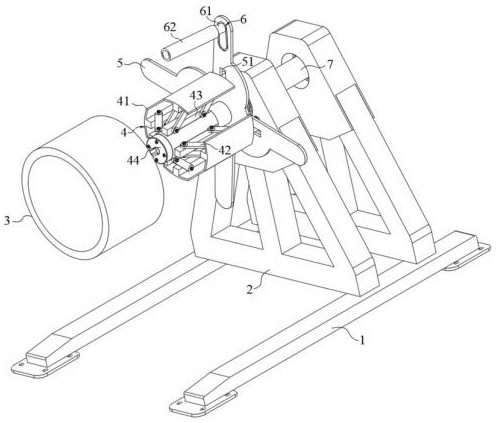

Ball arm sand blast apparatus

InactiveCN107322487AAvoid material breakImprove liquidityTransportation and packagingRotary stirring mixersSand blastingEngineering

The invention discloses a ball arm sand blast apparatus which comprises a sand blast machine body. A storage tank is arranged at the top of the sand blast machine body, an air compressor is connected to the end, far away from the sand blast machine body, of the storage tank, an outlet is formed in the end, far away from an air compressor, of the storage tank, a sand blast head is connected to the outlet through a first connecting pipe, a stirring device is arranged inside the storage tank and is used for evenly stirring materials, and the outlet is prevented from being blocked by material caking; the stirring device comprises a rotating rod, a stirring rod, a first stirring blade, a second stirring blade, a scraper blade, a gear and a connecting rack; and a standby application tank is arranged on one side of the storage tank. The ball arm sand blast apparatus is simple in structure and novel in design; the mobility and miscibility of the materials are increased through the stirring device, and caking blockage of the outlet is prevented; and meanwhile, the standby application tank is used for preventing a sand blast head from material breaking, a worker can be reminded in time, the sand blasting quality is guaranteed, and the practicability is high.

Owner:ANHUI AOFENG AUTOMOBILE FITTINGS

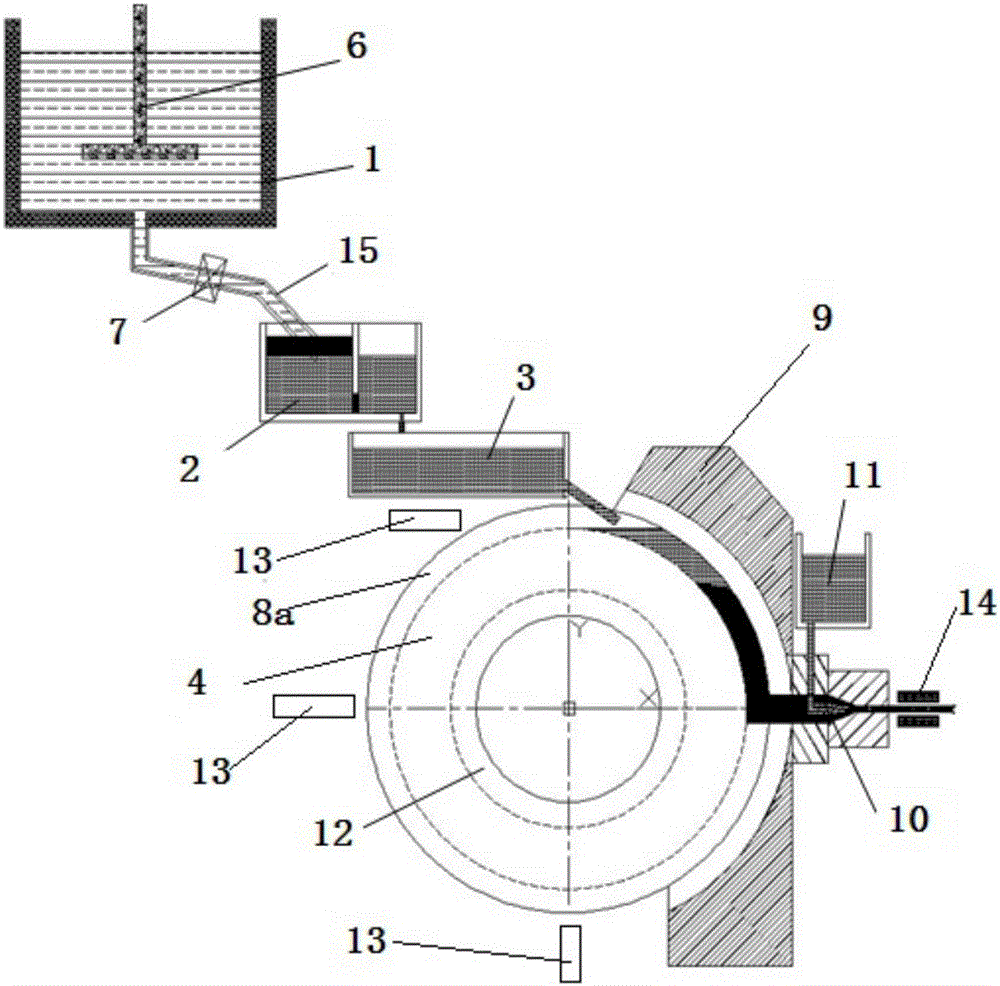

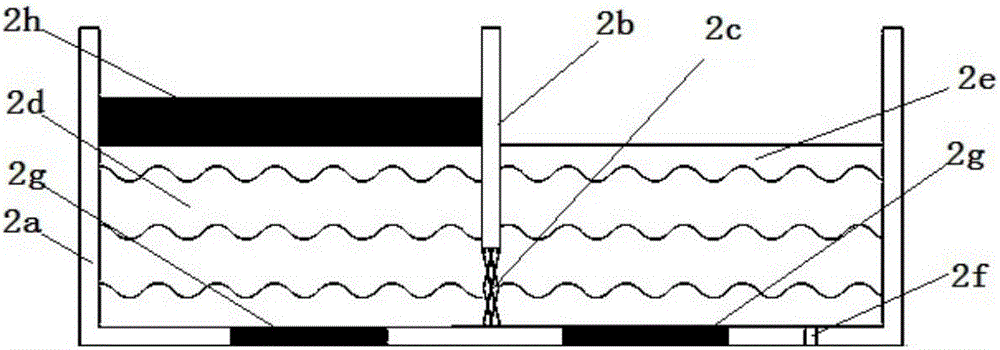

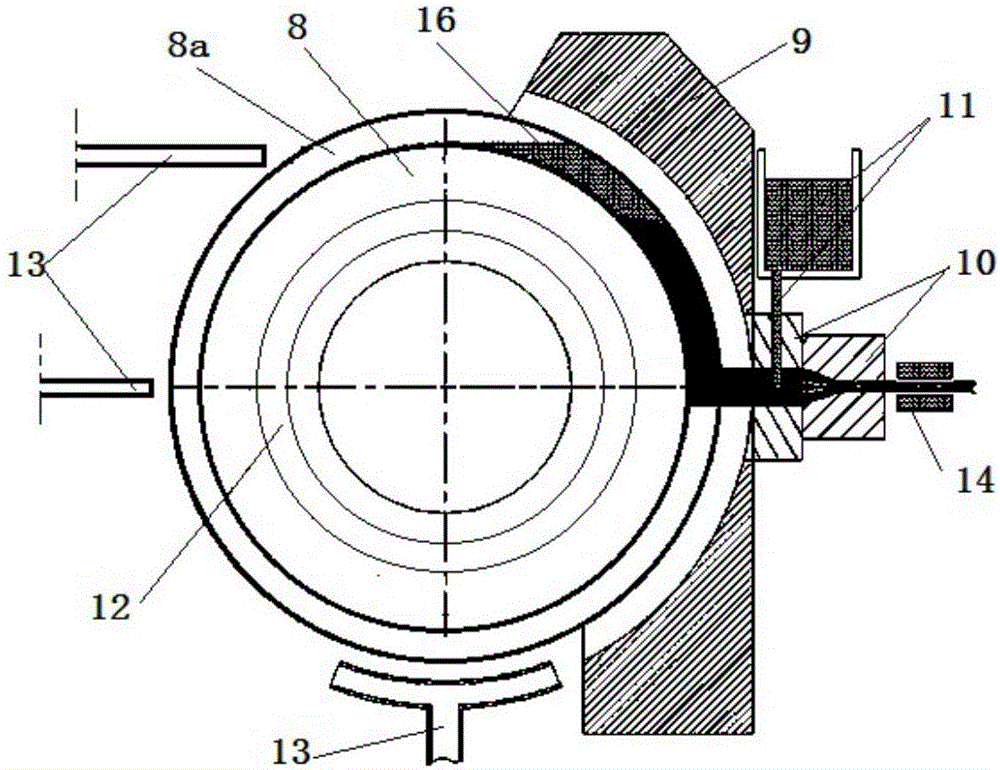

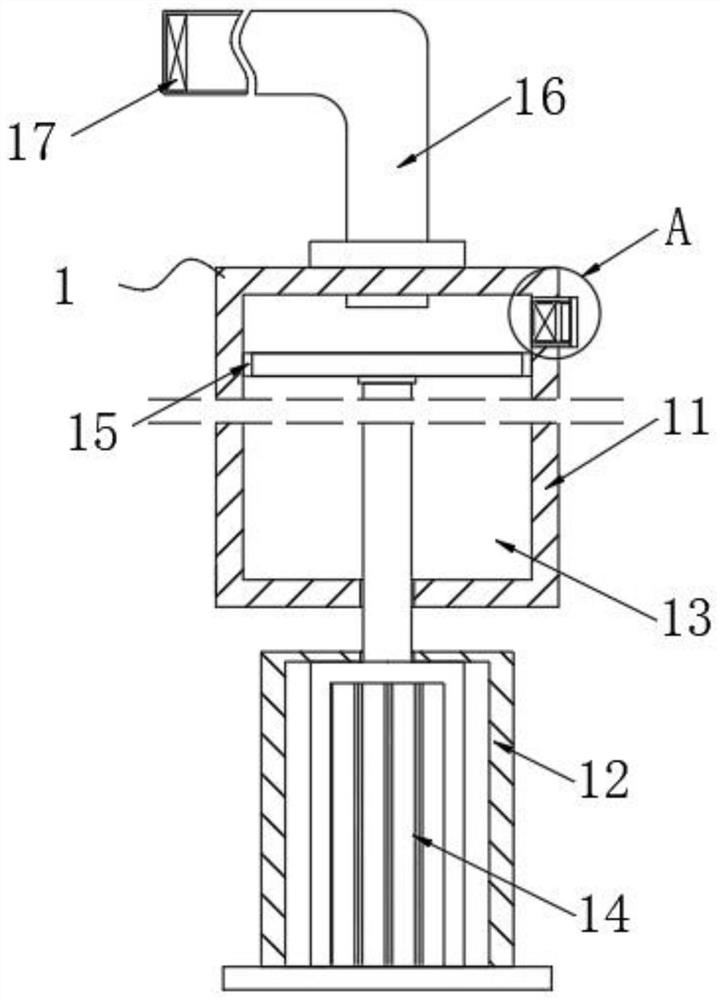

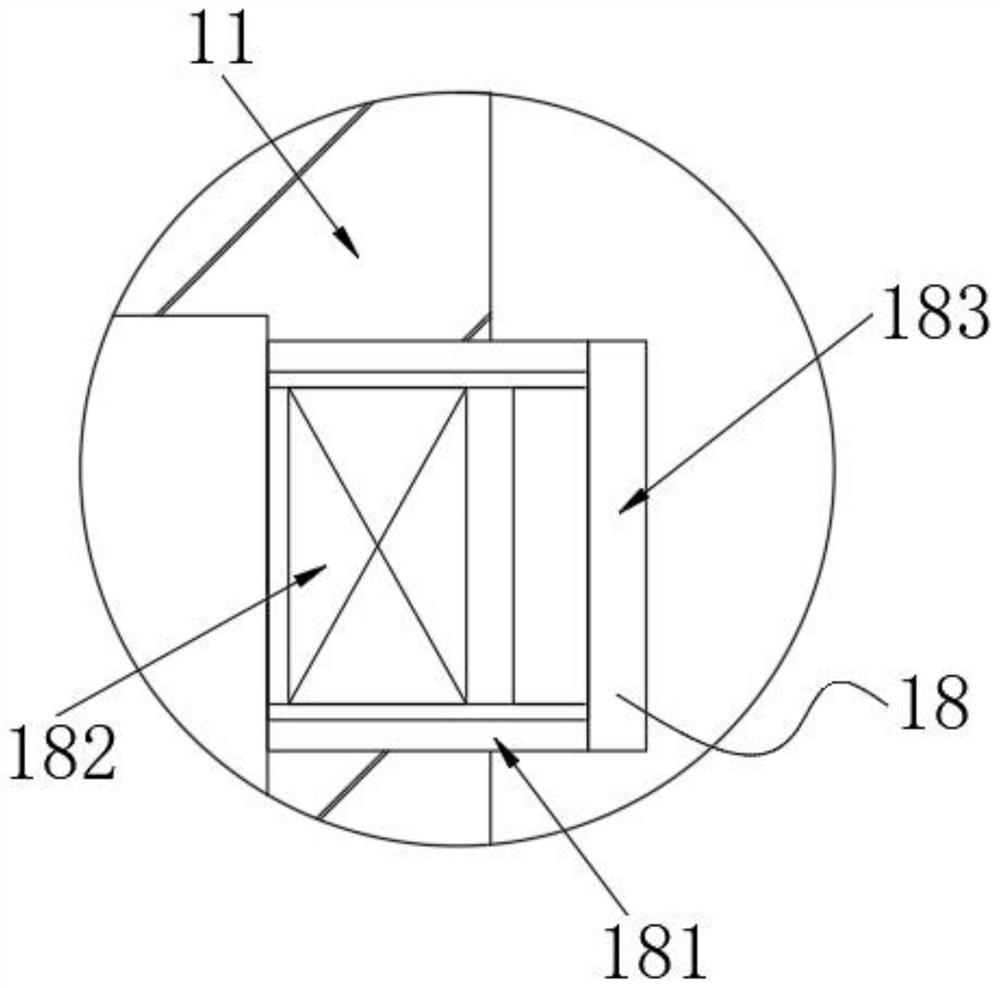

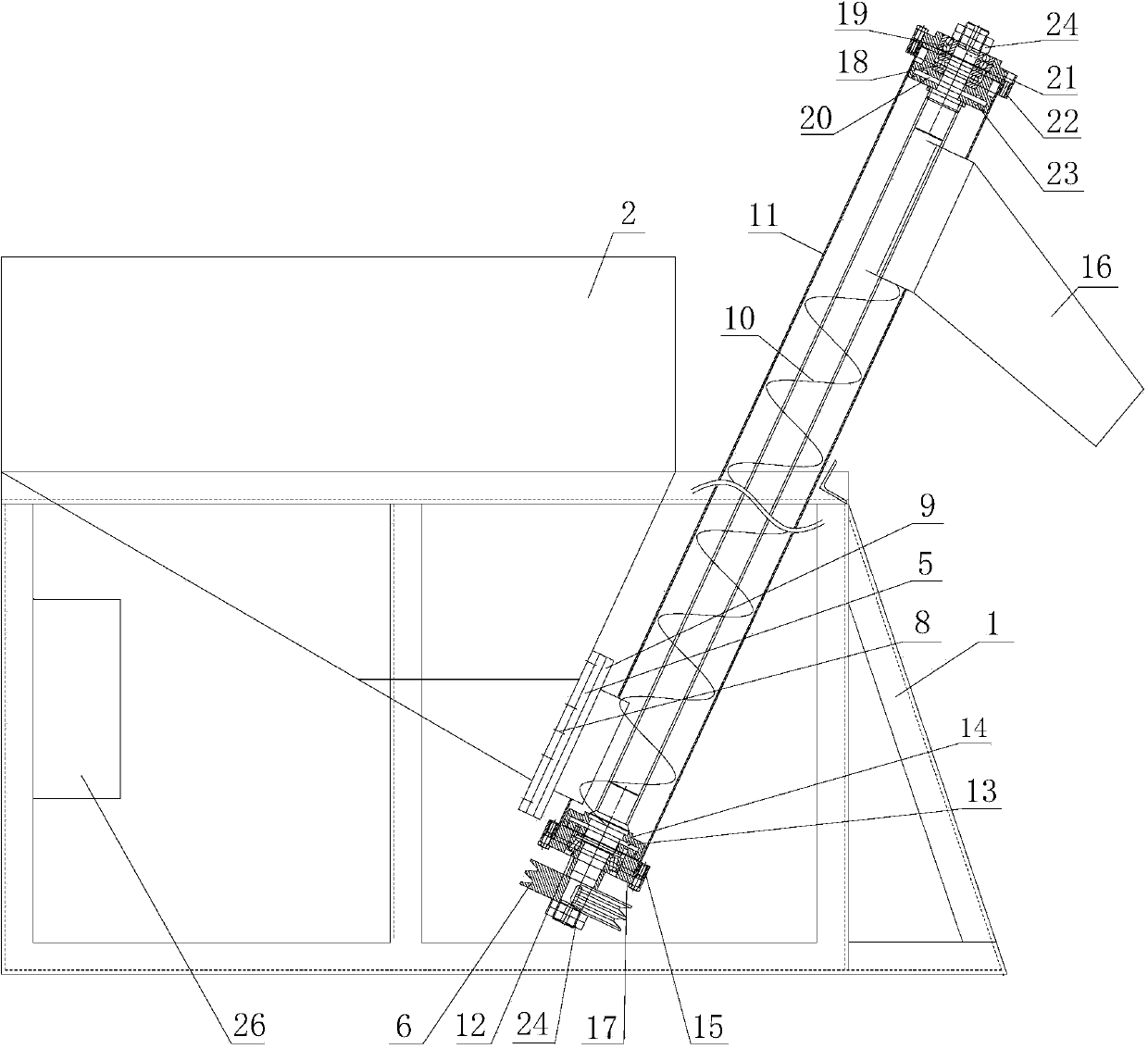

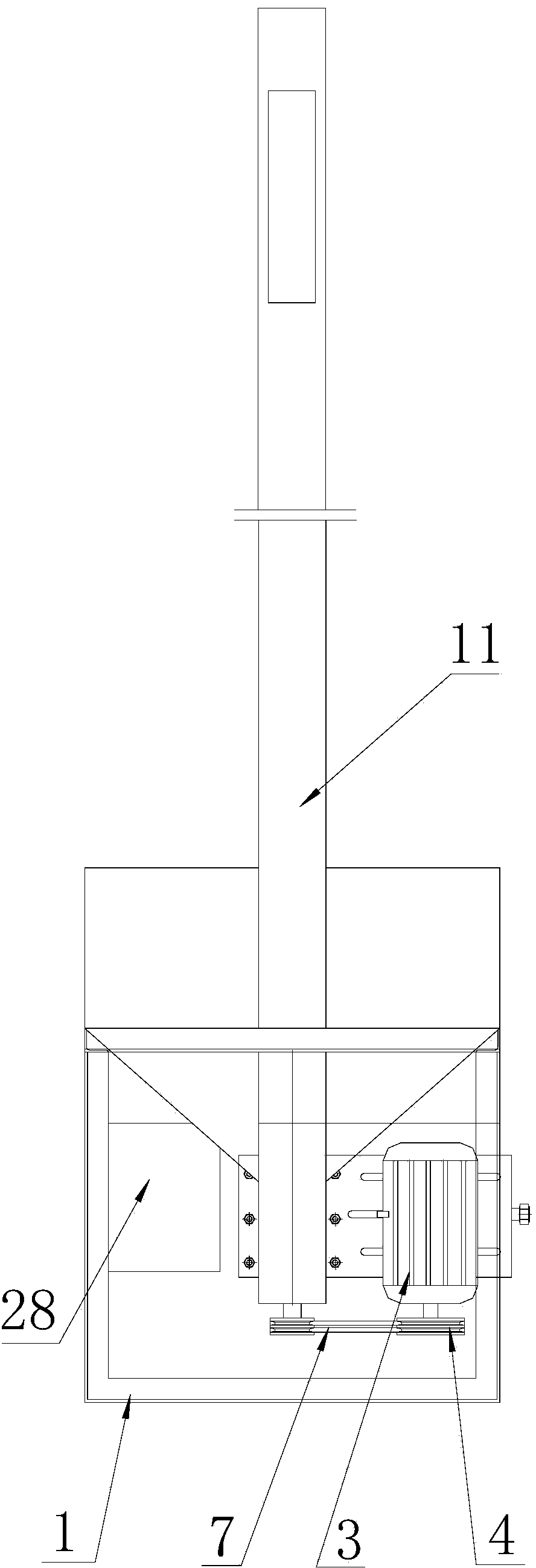

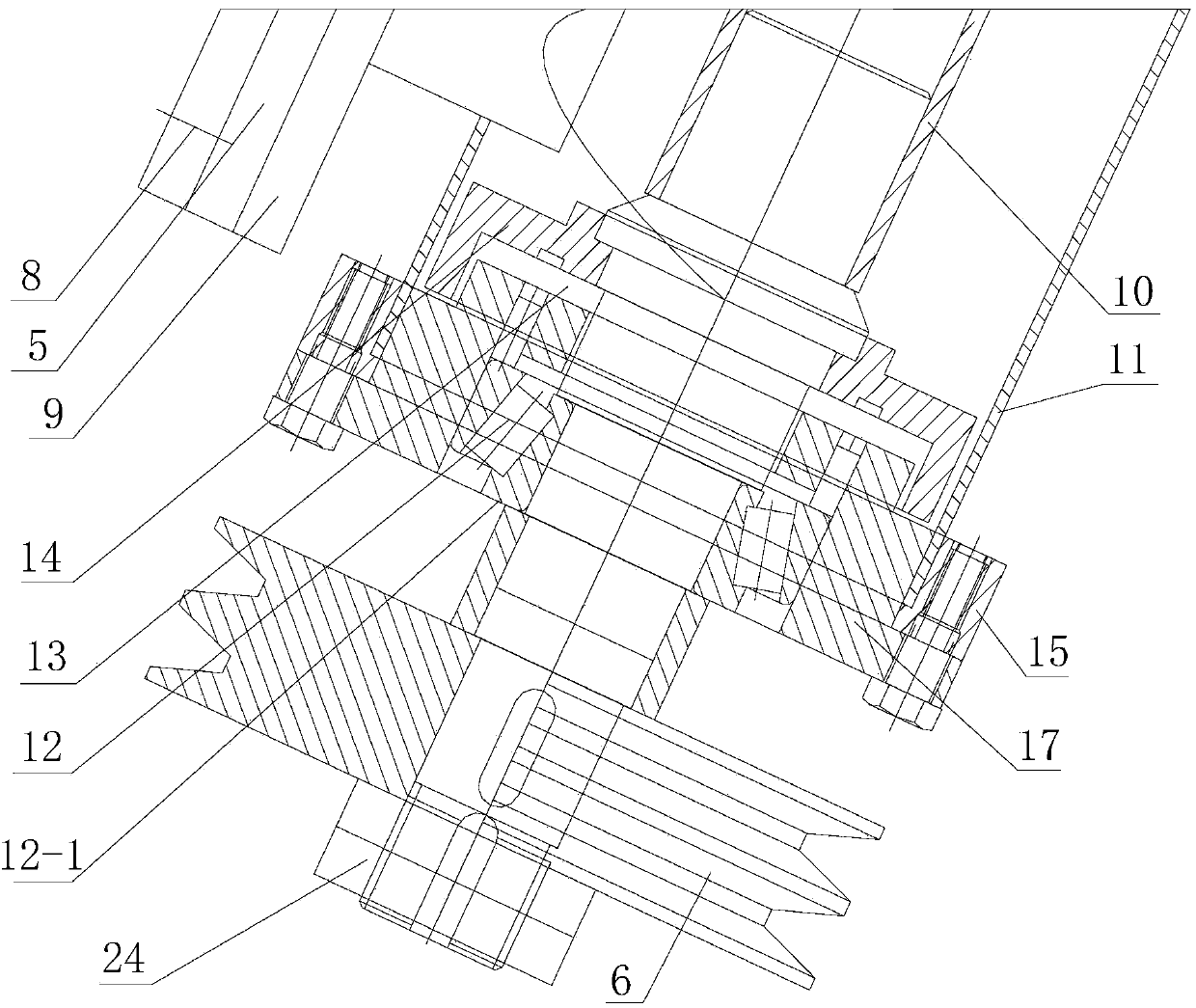

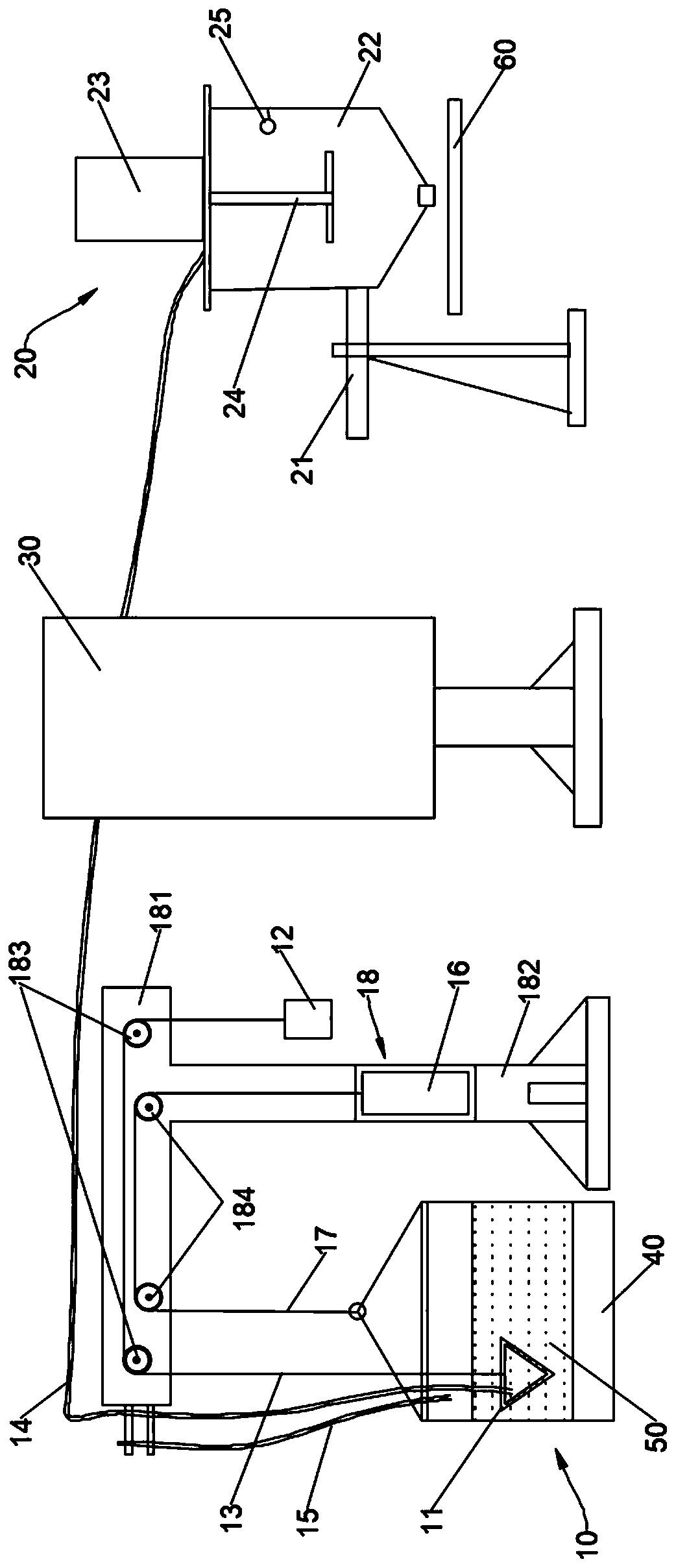

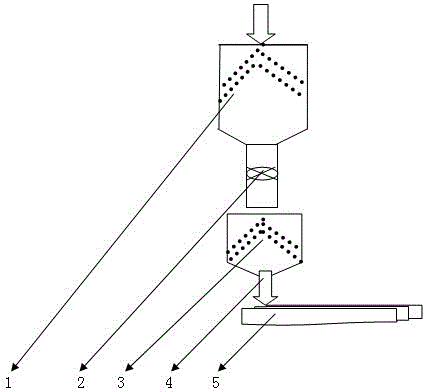

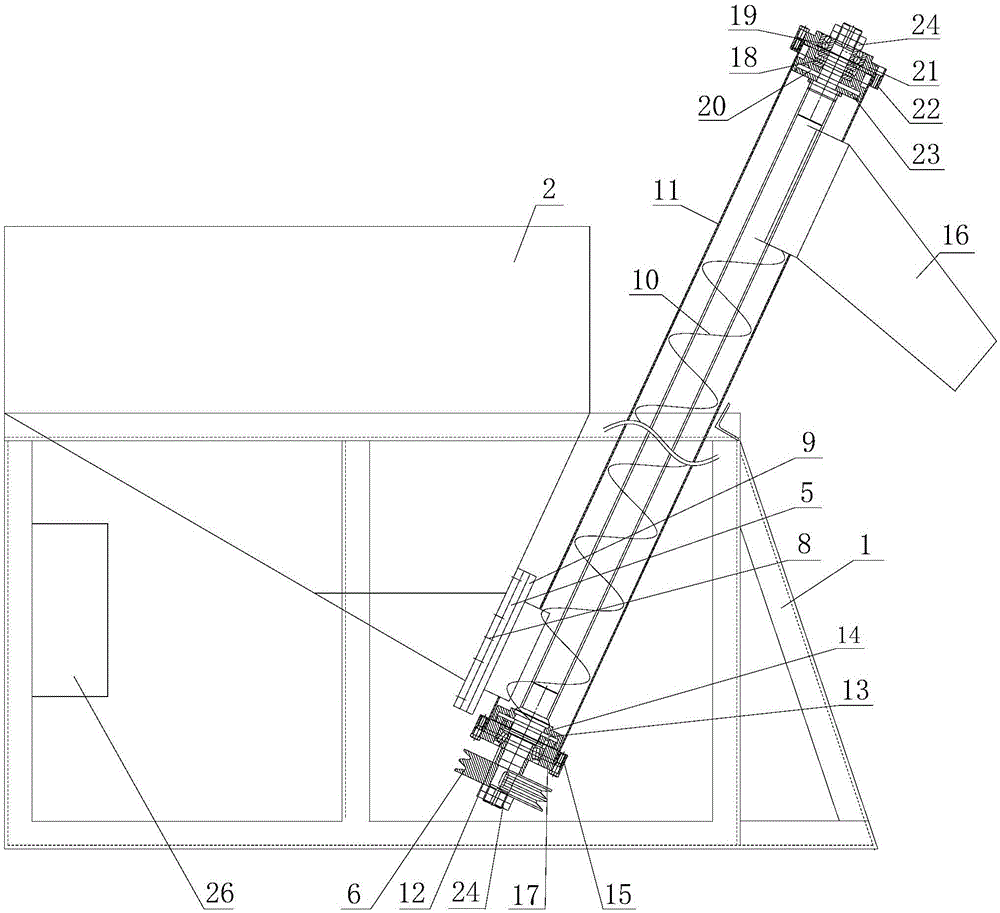

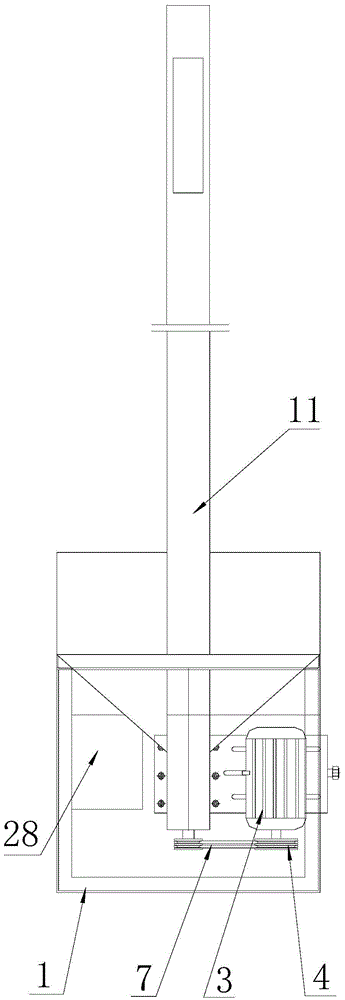

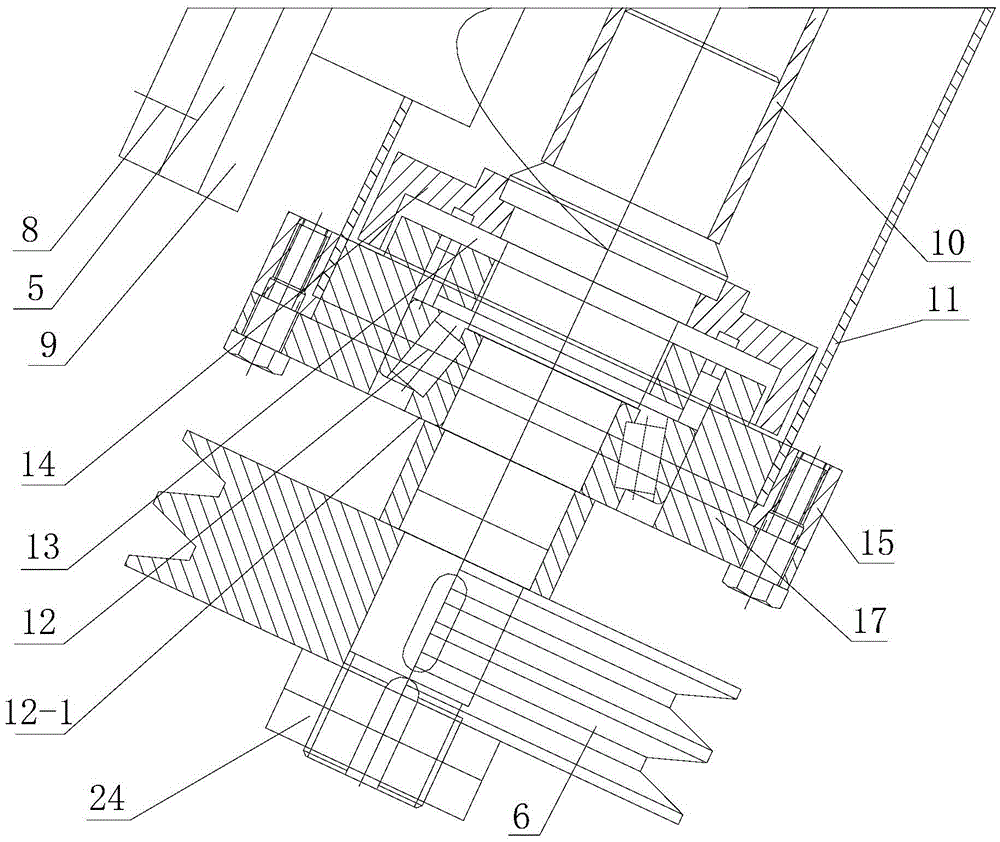

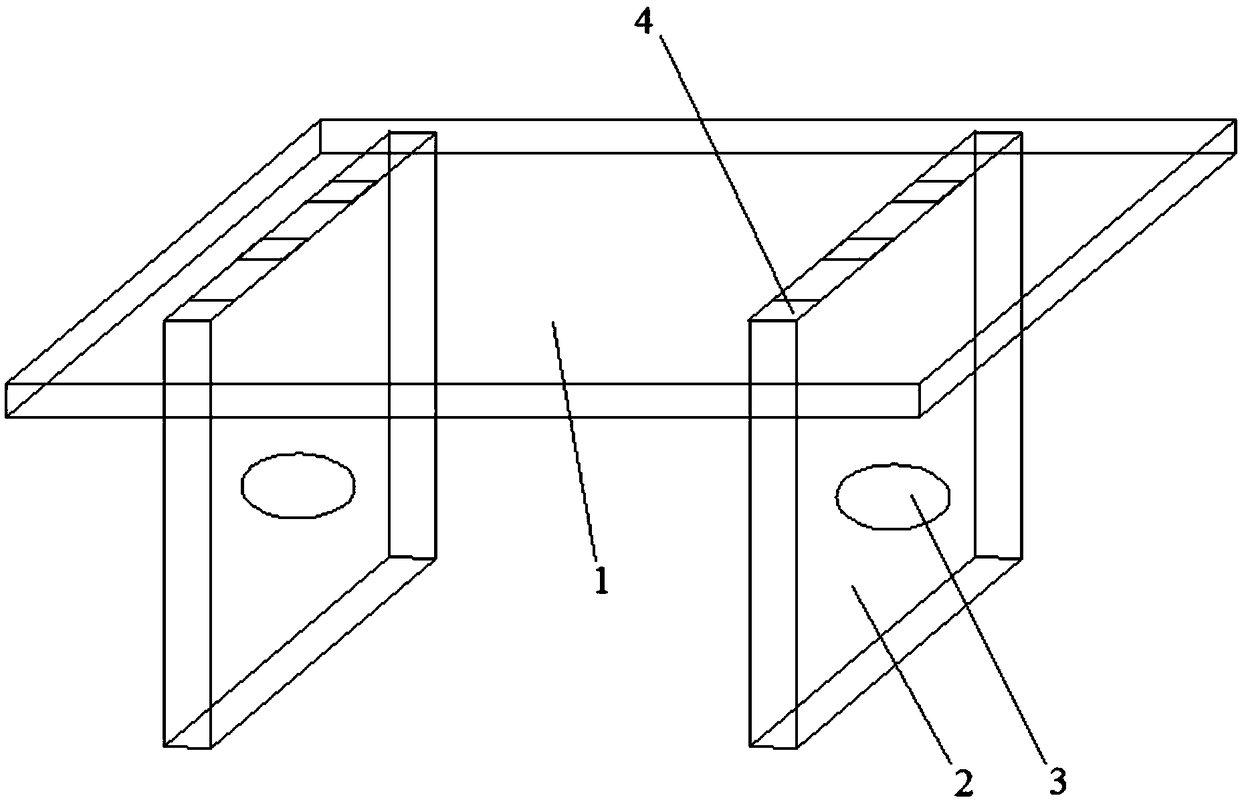

Core soldering tin bar continuous casting and extruding machining system and molding technology thereof

The invention discloses a core soldering tin bar continuous casting and extruding machining system and a molding technology thereof. Metal tin is molten in a rotating ventilation purifying furnace (1), nitrogen or hexachloroethane is led through a graphite rotator (6), and slag is brought out; molten tin flows into a heat preserving furnace (2), slag and impurities are blocked through a baffle and a filter screen, and purified melt enters a discharging cavity, flows into a flow furnace (3), and finally flows into a continuous extrusion machine (4); molten metal (16) flows to an extruding groove (8a) of a rotating extruding wheel, in the rotating process of the extruding wheel, solidifying and molding of the molten metal are completed, meanwhile, cold air blows the extruding groove through a ventilation pipe (13), heat of the extruding wheel is brought away, and cooling water in a cooling water circular channel (12) cools the extruding wheel; then, the molten metal enters a mold (10) through an extruding die (9), meanwhile, scaling powder is injected into the mold, casting and extruding are carried out, and a bar (15) is obtained. The production efficiency is high, an internal structure of a product is uniform, core breaking is not prone to happening, and the surface quality is good.

Owner:云南锡业新材料有限公司

Powder-making system automatic control method for heat engine plant steel ball coal grinding mill

The automatic control method for steel ball coal mill in thermal power plant adopts a double-layer control structure, including an upper layer of self optimizing algorithm and a lower layer of multidimensional fuzzy control algorithm. The self optimizing algorithm finds out the optimal inside coal storage quantity inside the coal mill, the optimal outlet temperature of the coal mill and the optimal inlet negative pressure value of the coal mill as the controlling set values; and the multidimensional fuzzy control algorithm realizes the automatic regulation of the coal feed quantity, the hot air valve opening, and the recirculating air valve opening or the cold air valve opening, so as to ensure the safe and reliable running of the steel ball coal mill system in optimal mode.

Owner:XI AN JIAOTONG UNIV +1

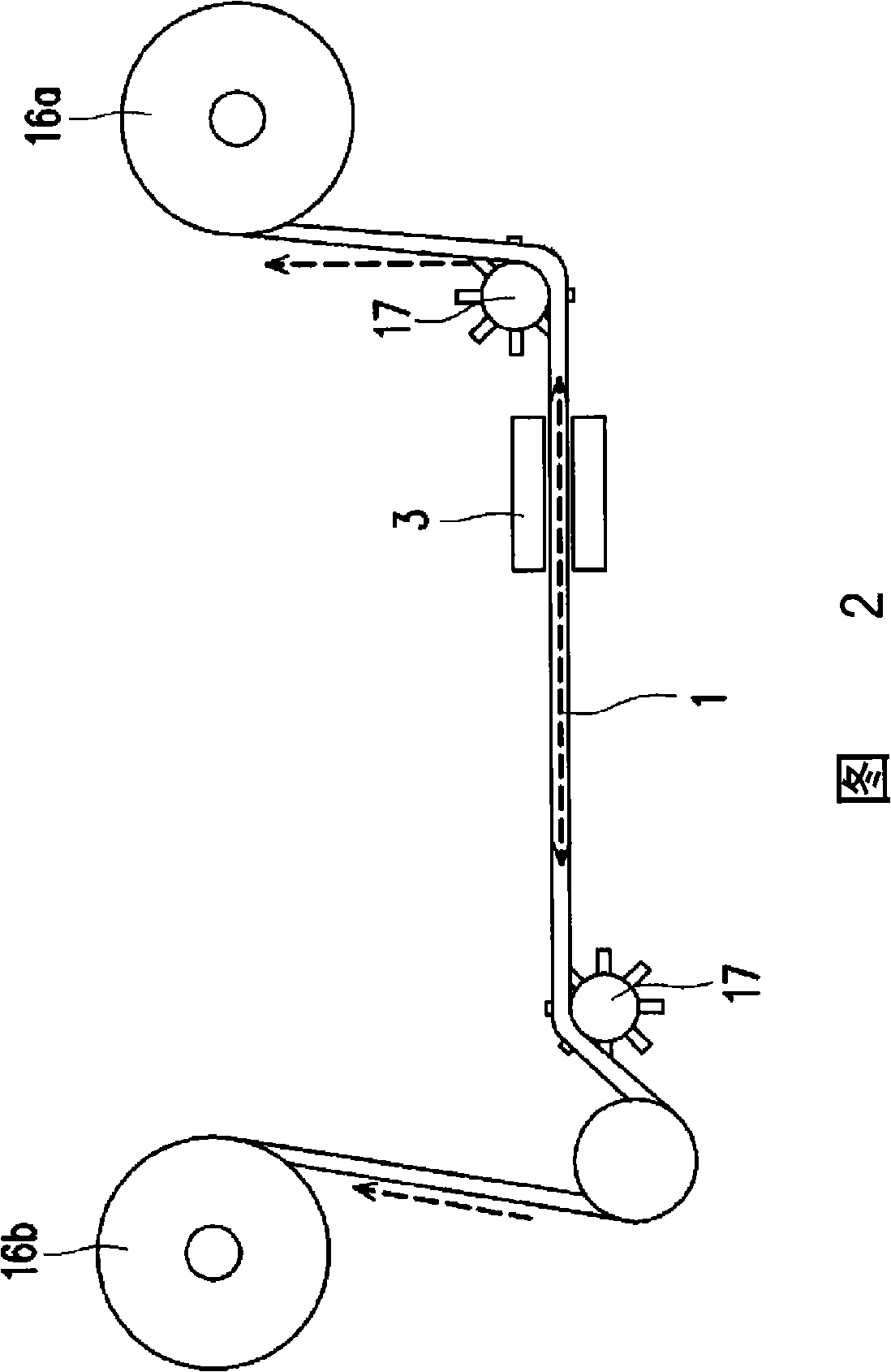

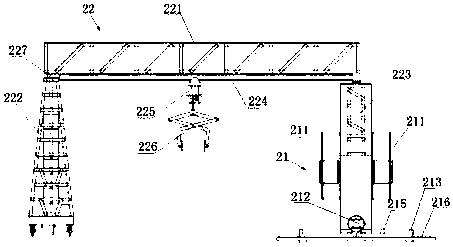

Particle carrier band forming system and process

The invention relate to a particle carrier band forming system and a process. The particle carrier band forming system comprises hot return air systems, a compound extrusion mold head, a forming mechanism, a punching module, a slitting module, a detecting device and a winding mechanism which are arranged in sequence from front to back; two sets of hot return air systems are arranged; material discharging mechanisms are connected with the lower ends of the two sets of hot return air systems respectively; screw rod extruding machines are connected with the material discharging mechanisms respectively; the two screw rod extruding machines are connected with the compound extrusion mold head; a trimming mechanism is arranged on the back side of the forming mechanism; and velocity matching mechanisms are arranged between the forming mechanism and the trimming mechanism, between the trimming mechanism and the punching module, and between the punching module and the slitting module. The particle carrier band forming system and process can save cost and improve production efficiency and product quality.

Owner:JIANGYIN WINPACK TECH

Automatic vermicelli production process with stable discharging

InactiveCN112120260AStable outputStable production processDomestic cooling apparatusDrying gas arrangementsDrive shaftProcess engineering

The invention discloses an automatic vermicelli production process with stable discharging. The automatic vermicelli production process specifically comprises the following steps: step I, introducingproduction raw materials for vermicelli into a mixing tank for mixing and processing, and removing bubbles, entrained in the raw materials in the mixing tank, by using a negative pressure mechanism. According to the automatic vermicelli production process with stable discharging, a sealing plate is pushed by a driving shaft of a servo electric cylinder I to move upwards in a negative pressure cavity; gas in the negative pressure cavity is discharged through an exhaust pipe; an electromagnetic valve switch is turned off; the sealing plate is pulled by the driving shaft of the servo electric cylinder I to move downwards in the negative pressure cavity; negative pressure is generated at the upper portion in the negative pressure cavity; the bubbles entrained in the raw materials in the mixingtank are removed through an air guide pipe, and the step is repeated for multiple times to complete removal of the bubbles entrained in the raw materials, thus effectively avoiding the bubbles entrained in the pulpy raw materials and the phenomenon of material breaking during discharging of an extruder; discharging of the vermicelli raw materials is stable; and the vermicelli production quality and production efficiency are relatively high.

Owner:HUAINAN YISHENG FOOD

Screw conveyor automatic feeding device in blown film production line

InactiveCN103587975AAvoid excessive humidityAvoid separationLoading/unloadingProduction lineAutomatic control

The invention relates to a screw conveyor automatic feeding device in a blown film production line. The screw conveyor automatic feeding device in the blown film production line comprises a storage hopper and is characterized in that the screw conveyor automatic feeding device further comprises a screw conveyor, a motor, a feeding starting electronic feedback device and a feeding stopping electronic feedback device, wherein the screw conveyor and the motor are located in the storage hopper and the feeding starting electronic feedback device and the feeding stopping electronic feedback device are arranged on an extruder hopper, an outer wall is fixedly arranged outside the screw conveyor, a screw conveyor sheave is connected with the lower end of the screw conveyor, one end of a motor shaft is provided with a motor sheave, and a screw conveyor power driving mechanism is formed by the motor sheave and the screw conveyor sheave through a driving belt; a thrust bearing assembly is arranged at the lower end of the screw conveyor and a self-aligning bearing assembly and a pressure bearing assembly are arranged at the upper end of the screw conveyor. Compared with a negative-pressure feeding device provided with a motor with the same power, the screw conveyor automatic feeding device in the blown film production line has the advantages that the screw conveyor automatic feeding device is in the feeding state for only 10 minutes per hour, so that energy consumption is reduced by 75%; dust separation is thoroughly avoided, raw materials are saved, and the problem of environment pollution is solved; the phenomenon that the humidity of the raw materials exceeds the standard due to the fact that the raw materials absorb too much moisture is prevented and the first-pass yield of products is improved to a large extent; allocation of manpower resources can be reduced through automatic control.

Owner:TIANJIN TIANSU SCI & TECH GROUP

Pulverizing loop ball mill load control method for cement factory

Owner:XI AN JIAOTONG UNIV +1

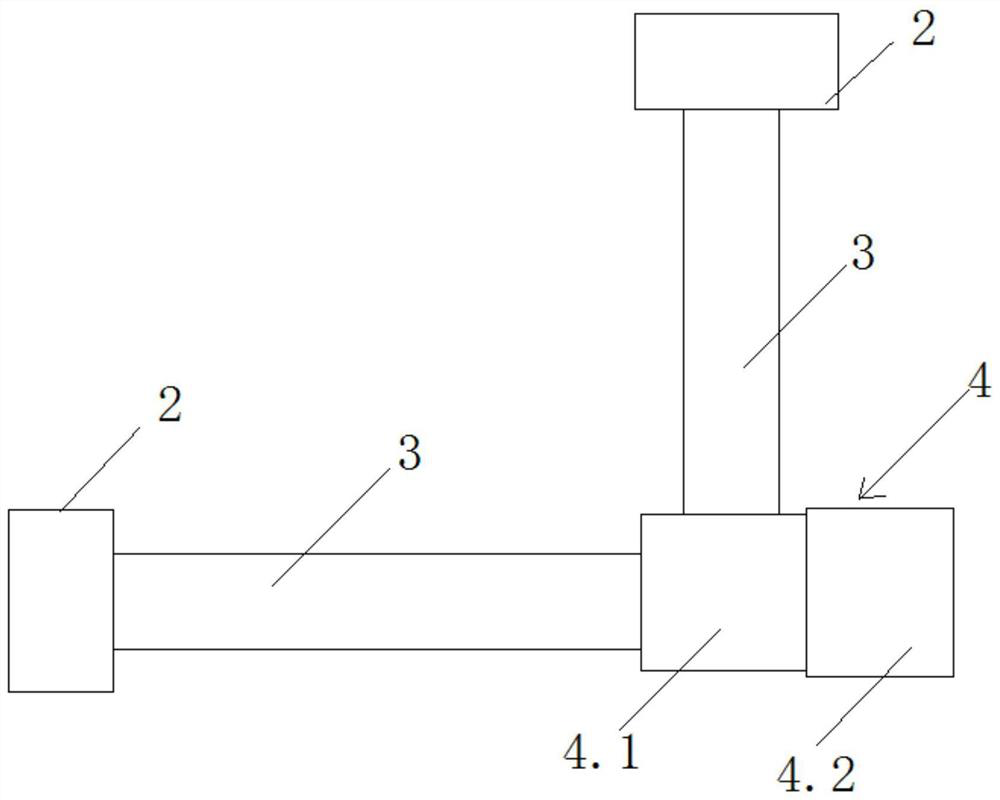

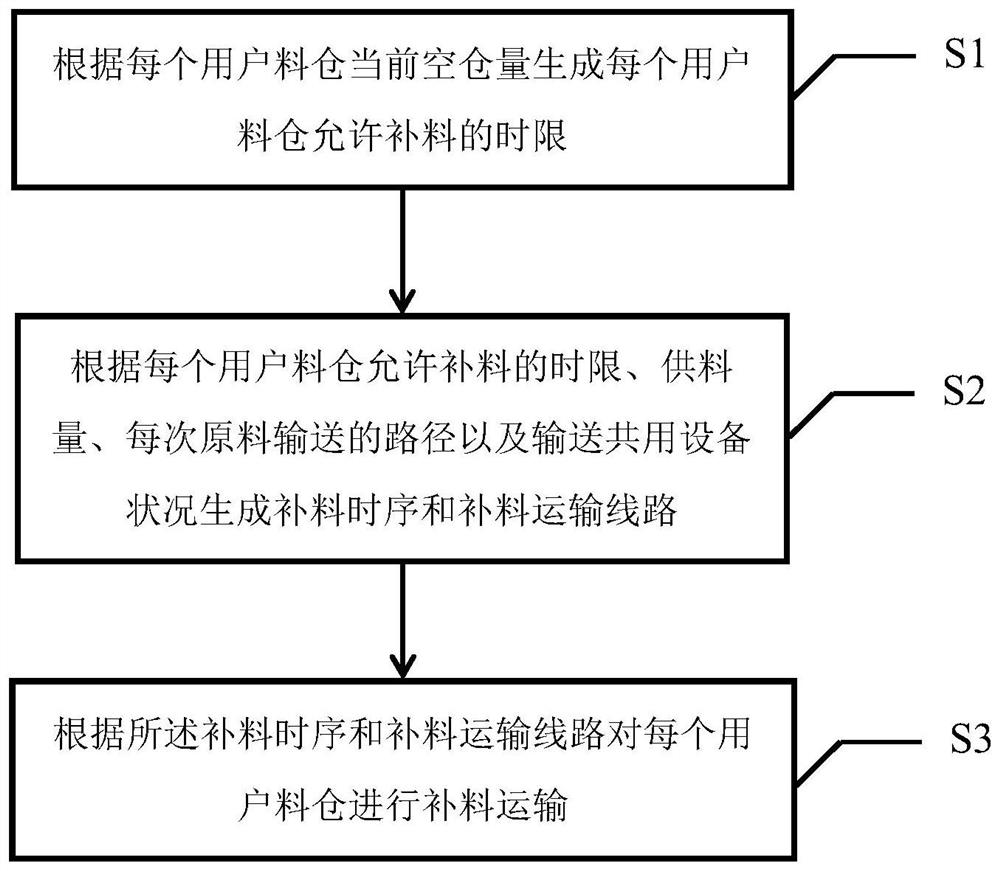

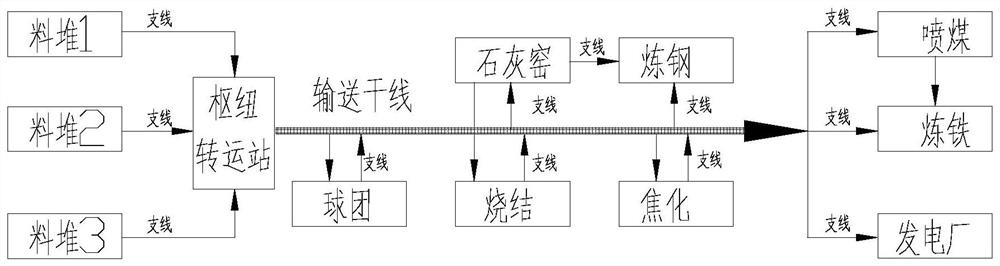

Material transportation method and device

PendingCN112561427AAvoid material breakSafe and orderly transportationLogisticsProcess engineeringMaterial supply

The invention provides a material transportation method and device. The method comprises the following steps of: generating a time limit for allowing material supplementation of each user bin according to the current empty bin amount of each user bin; generating a material supplementing time sequence and a material supplementing transportation line according to the allowable material supplementingtime limit of each user stock bin, the material supply amount, the path of each time of raw material transportation and the condition of transportation sharing equipment; and finally, supplementing and transporting each user stock bin according to the supplementing time sequence and the supplementing and transporting line. The problems that in a traditional stock bin transportation method, stockbin material breaking occurs, transportation is wrong, continuous operation cannot be achieved, the conveying efficiency is low, and the energy consumption is high can be effectively solved, and all-weather stock bin material safe and orderly feeding and compact energy-saving conveying are achieved.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

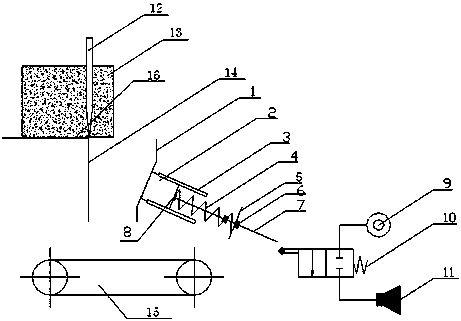

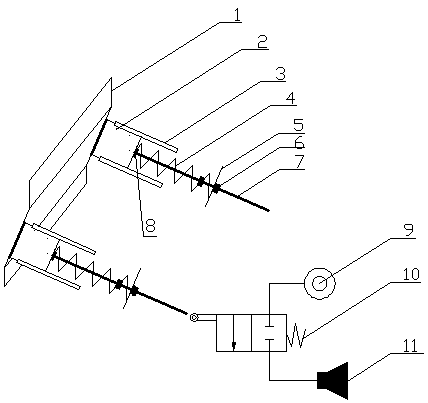

Blockage preventive device of tobacco slicing machine

PendingCN107549867AReduce the number of blockagesIncrease productivityTobacco treatmentMetal working apparatusEngineeringManufacturing line

The invention discloses a blockage preventive device of a tobacco slicing machine. The blockage preventive device comprises a cutter, a worktable, a downstream machine, a barrier, a guide plate, a reset mechanism and an alarm mechanism. The cutter is positioned above the worktable, the downstream machine is positioned below the barrier, and the barrier is fixedly arranged on the lower side of theworktable; the guide plate is positioned on the right side of the barrier, only tobacco bales with the sizes smaller than or equal to approval standards are allowed to pass gaps between the guide plate and the barrier, the alarm mechanism is elastically connected with the guide plate by the reset mechanism, the reset mechanism can be driven by the guide plate to move rightwards to trigger the alarm mechanism if the guide plate is squeezed when tobacco bales with the sizes larger than the approval standards fall down, the tobacco bales with the sizes larger than the approval standards can fallon the downstream machine, and the guide plate can be reset by the reset mechanism. The blockage preventive device has the advantages that the blockage frequencies of the tobacco slicing machine can be effectively reduced by the blockage preventive device, accordingly, the production continuity can be improved, and the production efficiency of enterprises can be improved; alarm effects can be realized for blockage, accordingly, operators can be reminded of timely handling blockage, and material deficiency of production lines can be prevented.

Owner:CHINA TOBACCO JIANGSU INDAL

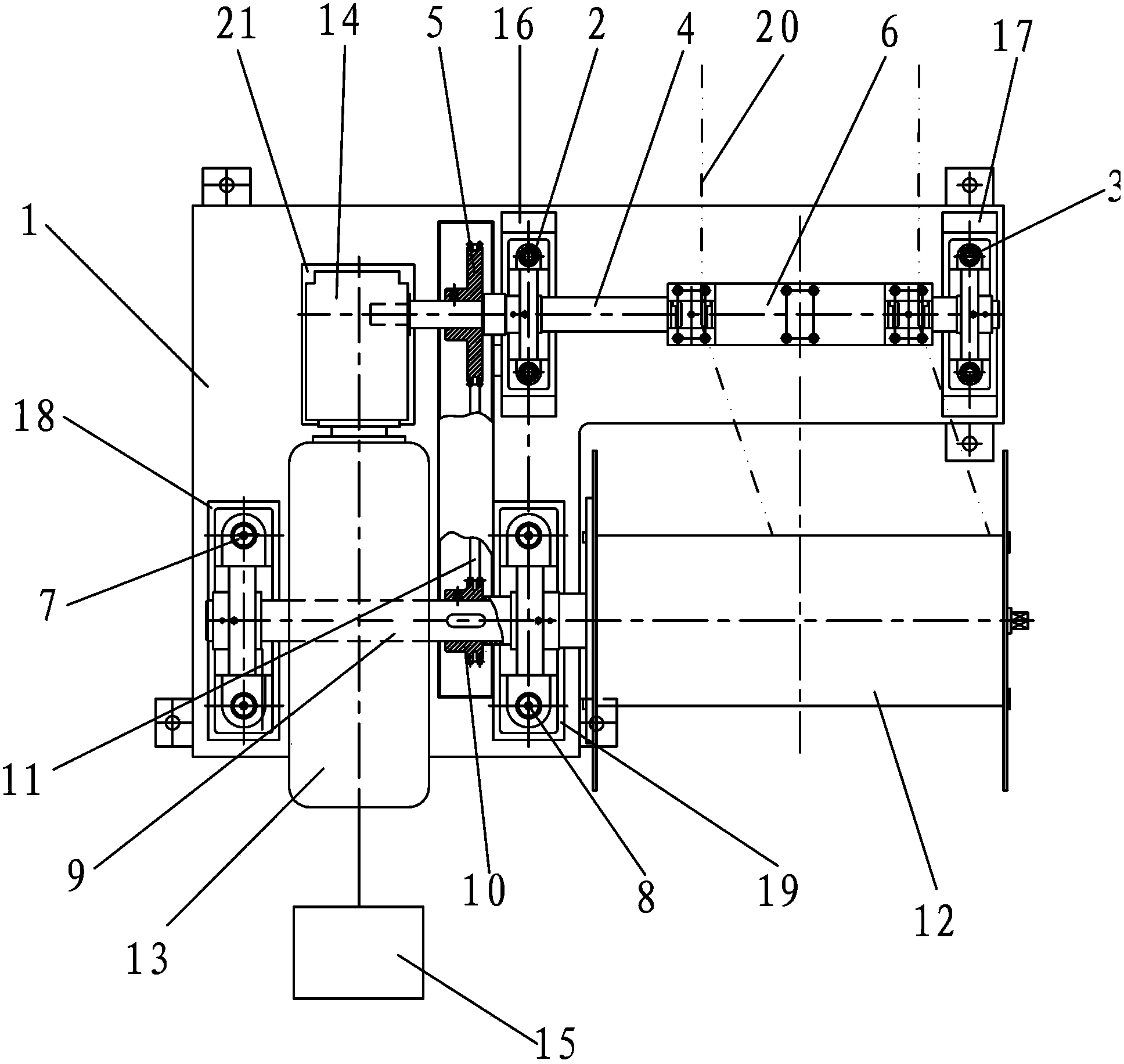

Rim charge winding device of slitting unit

InactiveCN103803328AThe overall structure is simple and reliableEasy to install and maintainWebs handlingControl systemPower control system

The invention discloses a rim charge winding device of a slitting unit. The rim charge winding device of the slitting unit comprises a base, a guide mechanism, a winding mechanism, a power mechanism and a power control system, wherein the power mechanism comprises a variable frequency motor and a speed reducer connected with the variable frequency motor; the guide mechanism comprises a first mounted bearing, a second mounted bearing and a lead screw; the shaft end of the lead screw extends into the speed reducer; the lead screw is provided with a first chain wheel and a guide barrel; the winding mechanism comprises a third mounted bearing, a fourth mounted bearing and a winding shaft; a second chain wheel right opposite to the first chain wheel is connected to the winding shaft; the first chain wheel and the second chain wheel are connected through a chain; the winding shaft is provided with a winding barrel used in cooperation with the guide barrel; the variable frequency motor is connected with the power control system. The rim charge winding device of the slitting unit is simple and reliable in structure, convenient to maintain and install and high in repeatability, the winding speed of rim charges is matched with the speed of the slitting unit, at the same time, winding with constant tension is achieved, the efficiency of the slitting unit is effectively improved, and the rim charge winding device of the slitting unit is high in practicability and convenient to popularize and use.

Owner:THE NORTHWEST MACHINE

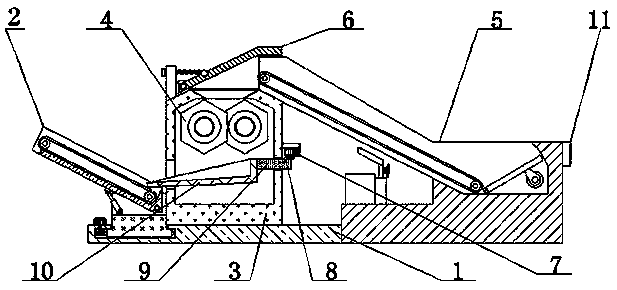

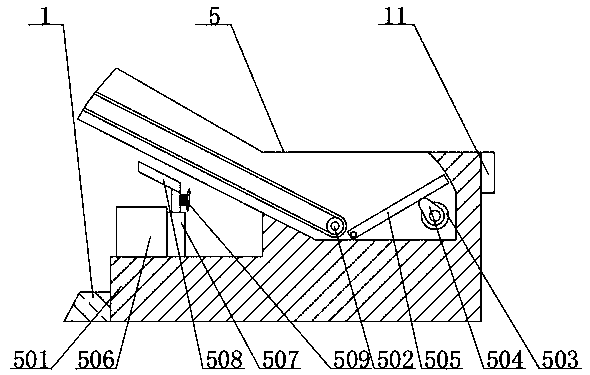

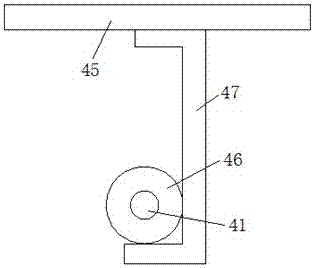

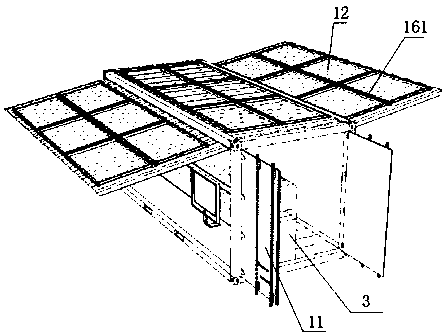

Standard movable light steel production line and self-adaption supply method thereof

ActiveCN108031716ASimple structureCompact structureMeasuring devicesMetal rolling arrangementsProduction lineElectricity

The invention relates to a standard movable light steel production line and a self-adaption supply method thereof. The production line comprises a standard box, a plate strip feeding device and lightsteel molding equipment; the light steel molding equipment is fixed in the standard box; the plate strip feeding device is placed in the standard box, and can be shifted outside the standard box; opening and closing doors are respectively arranged at the front and back ends of the standard box; two side box walls can be upwards overturned and fixed by any angles; solar power generation panels aredetachably fixed on the side box walls and the top of the box; multiple accumulators and inverters are arranged in the standard box; the solar power generation panels charge the accumulators; the accumulators supply electricity to the light steel molding equipment through the inverters; the plate feeding device comprises a feeding table; a feeding disc wound with a plate strip is arranged on the feeding table; and the feeding disc is driven to rotate by a servo motor.

Owner:FUJIAN LYUHUA ENERGY INVESTMENT CO LTD

Material sucking device and filling equipment

PendingCN111071504AGuaranteed continuous supplyGuaranteed water blocking effectSolid materialEngineeringStructural engineering

The invention discloses a material sucking device and filling equipment, and belongs to the technical field of optical cable manufacturing. The material sucking device is used for sucking a material in a packaging bag into a material filling device and comprises a material sucking head and a balancing weight, wherein the material sucking head is of a hollow structure with the side wall being provided with through holes, is arranged in the material in the packaging bag in a buried mode and communicates with the material filling device through a material sucking pipe, and the balancing weight and the material sucking head are connected through a first rope. The filling equipment comprises the material filling device and the material sucking device. The material sucking head is arranged in the material in the buried mode and balanced through the balancing weight, thus the material sucking head can automatically sink along with continuous reducing of the material in the packaging bag to ensure continuous material supplying to the material filling device, and the phenomenon of material discontinuing is avoided.

Owner:GUANGDONG HENGTONG PHOTOELECTRIC SCI & TECH +1

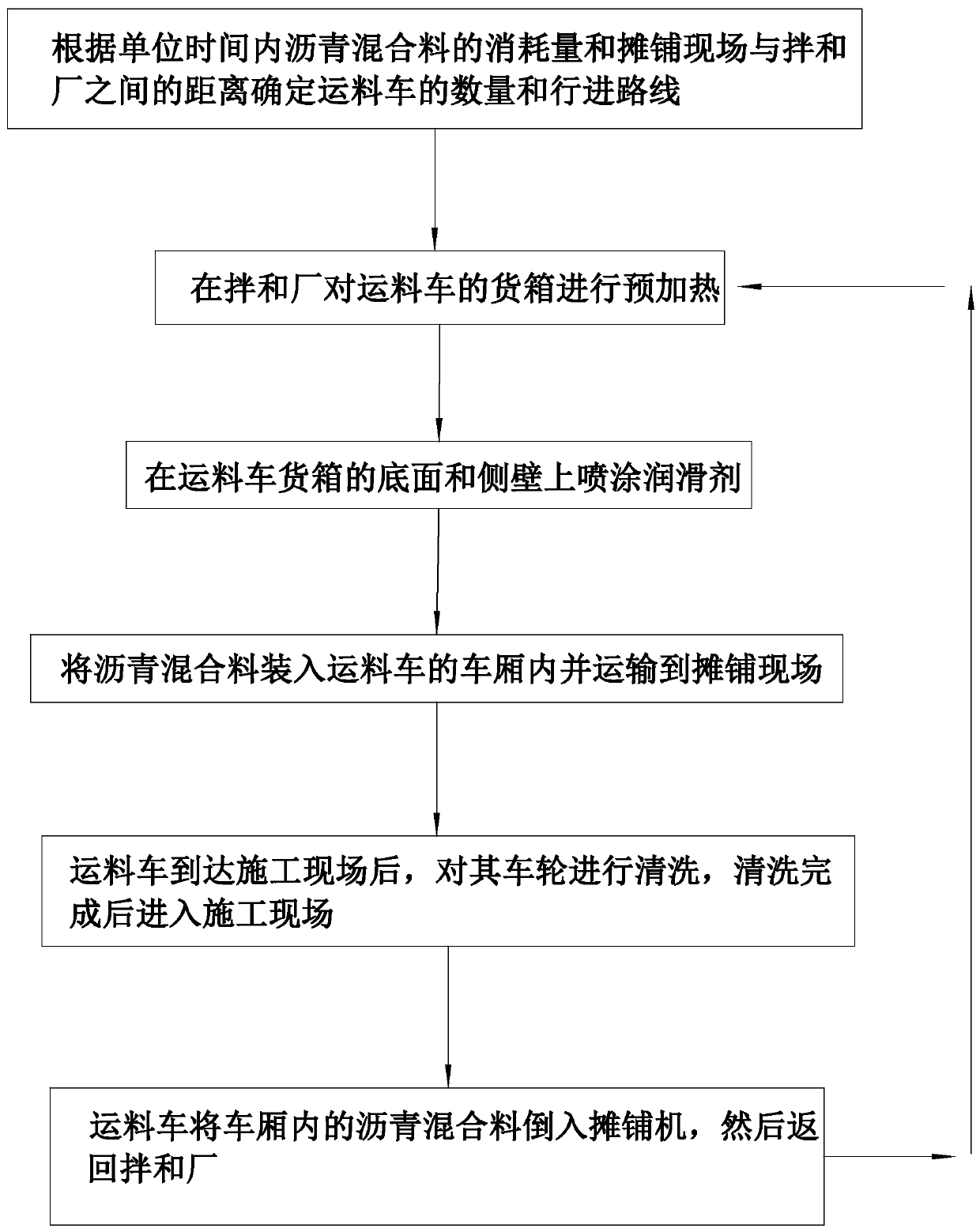

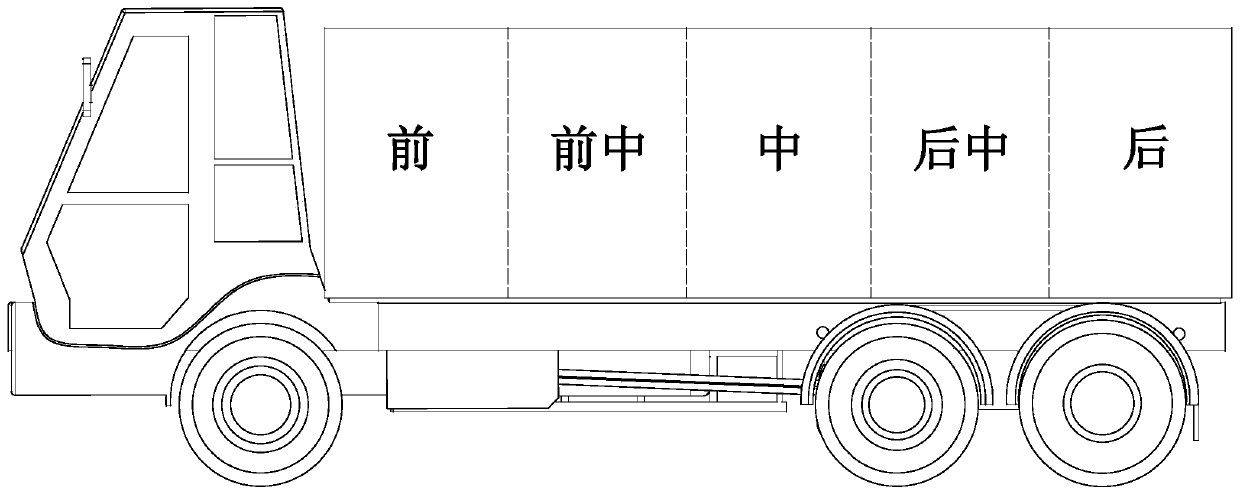

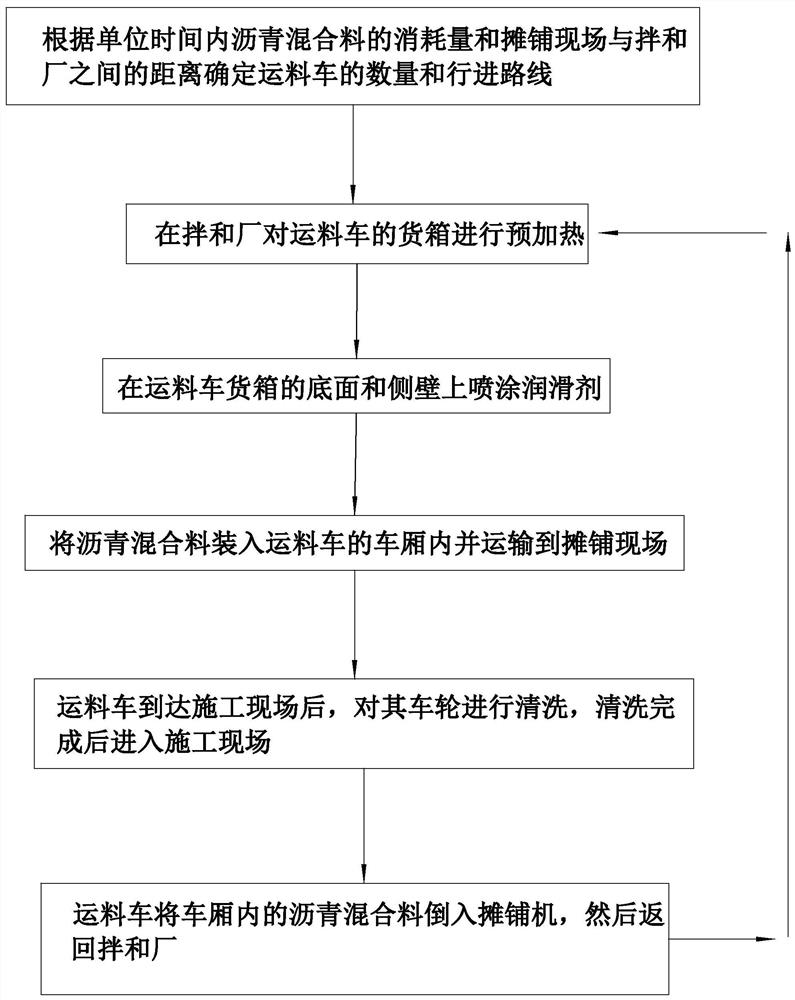

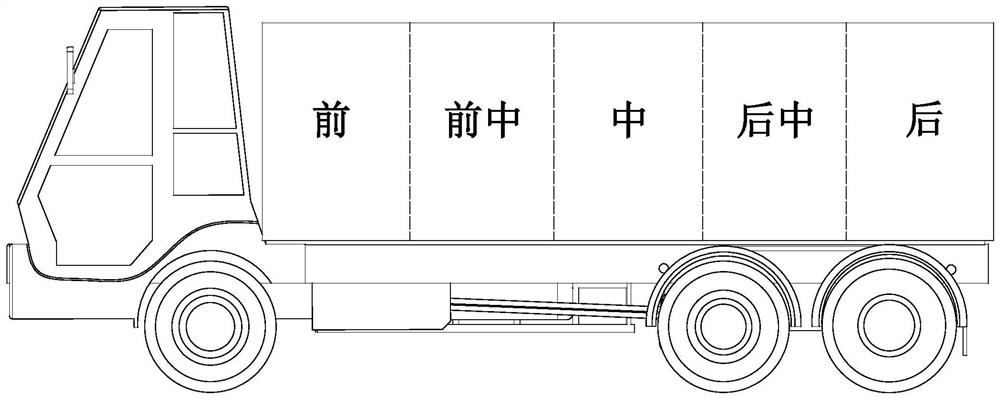

Asphalt mixture transportation method for expressway

The invention discloses an asphalt mixture transportation method for an expressway. The asphalt mixture transportation method comprises the steps that the number of material transportation vehicles iscalculated, an advance route is determined, the material transportation vehicles are preheated, lubricant is sprayed, vehicles are loaded, heat preservation is conducted, transportation is conducted,and cleaning is conducted, the number of the material transportation vehicles is determined according to production capacity, transport time, consumption and the like of a mixing plant, safety reserve vehicles are increased, and occurrence of material stopping of paving is avoided. Material transportation vehicle pre-heating, lubricant spraying, heat preservation and other measures can minimize probability of segregation of an asphalt mixture, and the effects of improving the quality of asphalt pavement, prolonging the service life of the pavement, and lowering the cost of later maintenance are realized.

Owner:河北交规院瑞志交通技术咨询有限公司

A method of transporting asphalt mixture for expressways

The invention discloses a method for transporting asphalt mixture for expressway, which comprises the steps of counting the number of transport vehicles, determining the traveling route, preheating the transport vehicles, spraying lubricant, loading, heat preservation, transportation, cleaning and the like. The number of transport vehicles is determined according to the production capacity, transportation time and consumption of the mixing plant, and additional safety reserve vehicles can avoid paving material breakage. Measures such as preheating of the transport vehicle, spraying lubricant and heat preservation can minimize the probability of segregation of the asphalt mixture, improve the quality of the asphalt mixture, improve the quality of the asphalt pavement, prolong the service life of the pavement and reduce the maintenance cost in the later period effect.

Owner:河北交规院瑞志交通技术咨询有限公司

Control system for conveying and metering of granules

The invention relates to a control system for conveying and metering of granules. The control system comprises a PLC controller, a metering bin connected with the PLC controller and a cylinder solenoid valve, wherein the cylinder solenoid valve drives and controls the motion of a blanking baffle plate, the PLC controller is embedded with PLC programming software, a rectangular pulse generator which controls the blanking baffle plate directly through the cylinder solenoid valve is in a series connection with a blanking baffle plate control output point of the PLC programming software and comprises the pulse timer T0 and the pulse timer T1, which are in a parallel connection, the pulse timer T0 and the pulse timer T1 are respectively in a series connection with normally-closed contacts of T1' and T0' so as to realize reciprocal interlocking, a T0 output point is constructed as a control output point of the blanking baffle plate, and an input value of timing pulse width of the rectangular pulse generator is set to be in a range of 0 to 27 s in the PLC programming software. The control system provided in the invention has stable and reliable performance, can prevent occurrence of unexpected events, totally avoids the phenomenon of cutting-off of a raw material, eradicates potential safety hazards of cutting-off and stopping of a production line and is convenient and reliable.

Owner:ANHUI GUOFENG PLASTIC

Blown film production line auger automatic feeding device

InactiveCN103587975BAvoid excessive humidityAvoid separationLoading/unloadingProduction lineThrust bearing

Owner:TIANJIN TIANSU SCI & TECH GROUP

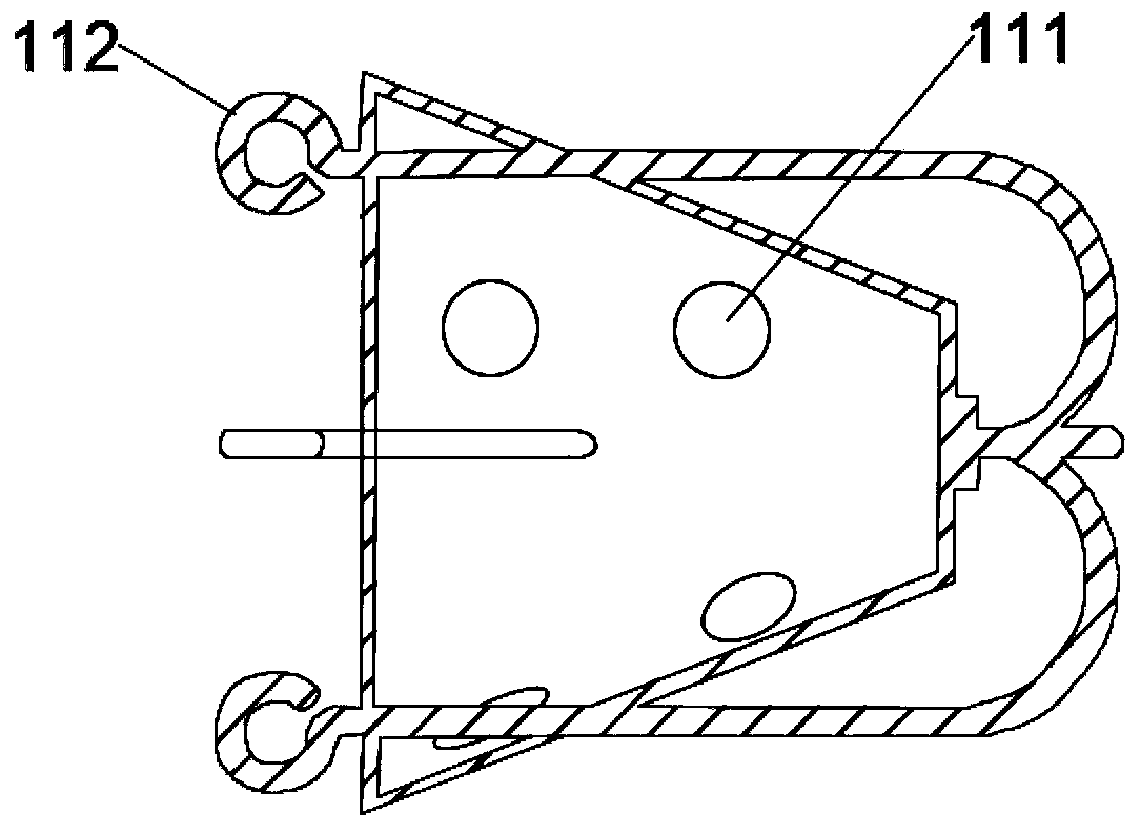

Anti-collision damper support and production method thereof

InactiveCN108980269AAvoid material breakConnection fitNon-rotating vibration suppressionWear resistantEngineering

The invention provides an anti-collision damper support and a production method thereof. The anti-collision damper support comprises a mounting base plate, two damper fixing plates symmetrically arranged at the bottom of the mounting base plate and damper protective jackets and is characterized in that damper fixing holes are formed in the damper fixing plates; the mounting base plate is providedwith through holes, the damper fixing plates are provided with protrusions, the damper fixing plates are arranged on the mounting base plate in an inserted manner through the protrusions, the top of the mounting base plate is provided with grooves, wear-resistant rubber is arranged in the grooves, and the outer periphery of the mounting base plate is provided with a plurality of mounting holes; the damper protective jackets are arc-shaped resin protective jackets which sleeve dampers. The anti-collision damper support is resistant to vibration and capable of guaranteeing that the dampers can be normally used during the intense bump or collision of a vehicle.

Owner:WUHU HONGKUN AUTO PARTS

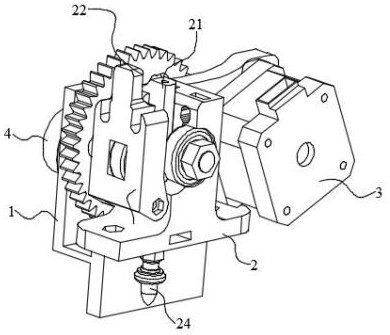

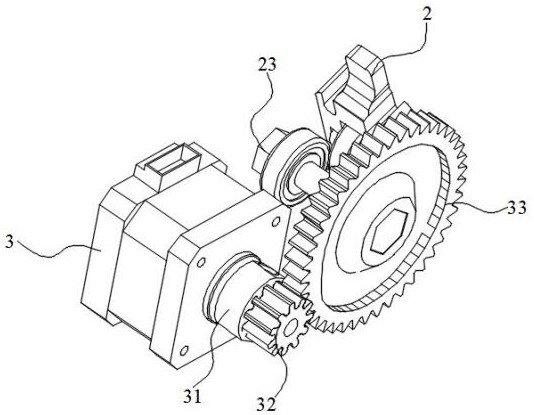

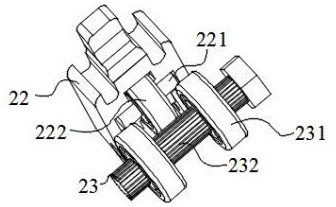

Material conveying and spraying device for 3D printing

PendingCN113524661AIncrease contact frictionAvoid material breakAdditive manufacturing apparatus3D object support structuresElectric machineryEngineering

The invention discloses a material conveying and spraying device for 3D printing. The material conveying and spraying device for 3D printing comprises a mounting main body frame and a fixing frame fixed to one end of the mounting main body frame, a mounting and dismounting structure is mounted on one side of the mounting main body frame, a motor is mounted on one side of the mounting main body frame, and a rotating shaft is mounted at the output end of the motor through a coupler. A driving gear is fixed to the end, away from the motor, of the rotating shaft, a driven gear is engaged with one side of the driving gear, a conveying shaft is arranged at the center position of the driven gear, the two ends of the conveying shaft are each sleeved with a driving disc in the axial direction, and a short guide cylinder is fixed to one side of the fixing frame. The side, away from the driving discs, of the conveying shaft is fixedly connected with one side of the mounting main body frame. According to the material conveying and spraying device for 3D printing, the mounting and dismounting structure is arranged on the mounting main body frame, the conveying shaft is arranged on the fixing frame, and a fixing disc is directly arranged on a positioning column on the surface of the printing device, so that the phenomena of material breakage and the like are avoided, and meanwhile the spraying position can be conveniently and randomly adjusted.

Owner:ANHUI CHUNGU 3D PRINTING INTELLIGENT EQUIP IND TECH RES INST CO LTD

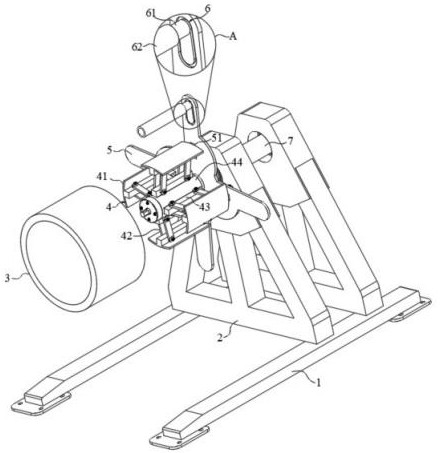

Feeding device capable of preventing material breakage and used for 3D printing

PendingCN113510929AAvoid material breakAvoid the risk of material breakageAdditive manufacturing apparatus3D object support structuresManufacturing engineering3D printing

Owner:ANHUI CHUNGU 3D PRINTING INTELLIGENT EQUIP IND TECH RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com