Standard movable light steel production line and self-adaption supply method thereof

A production line, mobile technology, used in length measuring devices, metal processing equipment, metal rolling, etc., can solve the problems of difficult to achieve rapid production to meet needs, inconvenient transportation, inconvenient assembly, etc., to facilitate overall transportation and save installation. Time, high applicability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

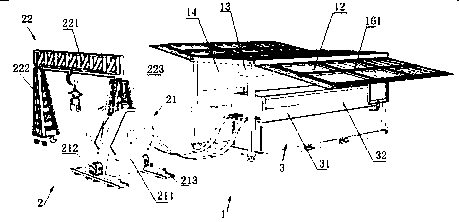

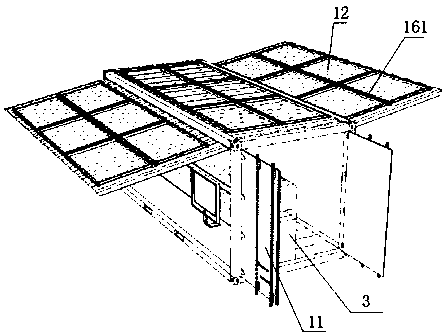

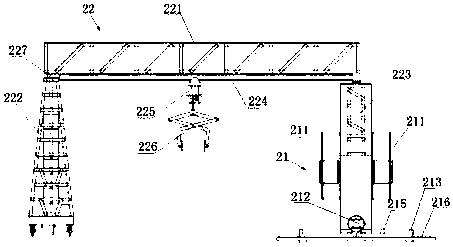

[0061] Such as Figures 1 to 3 As shown, a standardized mobile light steel production line includes a standardized box body 1, a strip feeding device 2 and a light steel forming equipment 3; the light steel forming equipment 3 is fixed in the standardized box body 1, and the strip feeding device The device 2 is placed in the standardized box 1 and can be moved out of the standardized box 1; the front and rear ends of the standardized box 1 are respectively provided with opening and closing doors 11, and the box walls on both sides can be turned up and fixed at any angle. A solar power generation panel 12 is detachably fixed on the box wall and the top of the box body; several batteries 13 and inverters 14 are arranged in the standardized box 1; the solar power generation panel 12 charges the battery 13; The transformer 14 supplies power for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com