Core soldering tin bar continuous casting and extruding machining system and molding technology thereof

A processing system and bar technology, applied in the field of cored solder bar production equipment and production technology, can solve the problems of low production efficiency of cored solder wire, uneven internal structure, poor product surface quality, etc., and achieve melt purification Continuity with forming, uniform internal structure and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

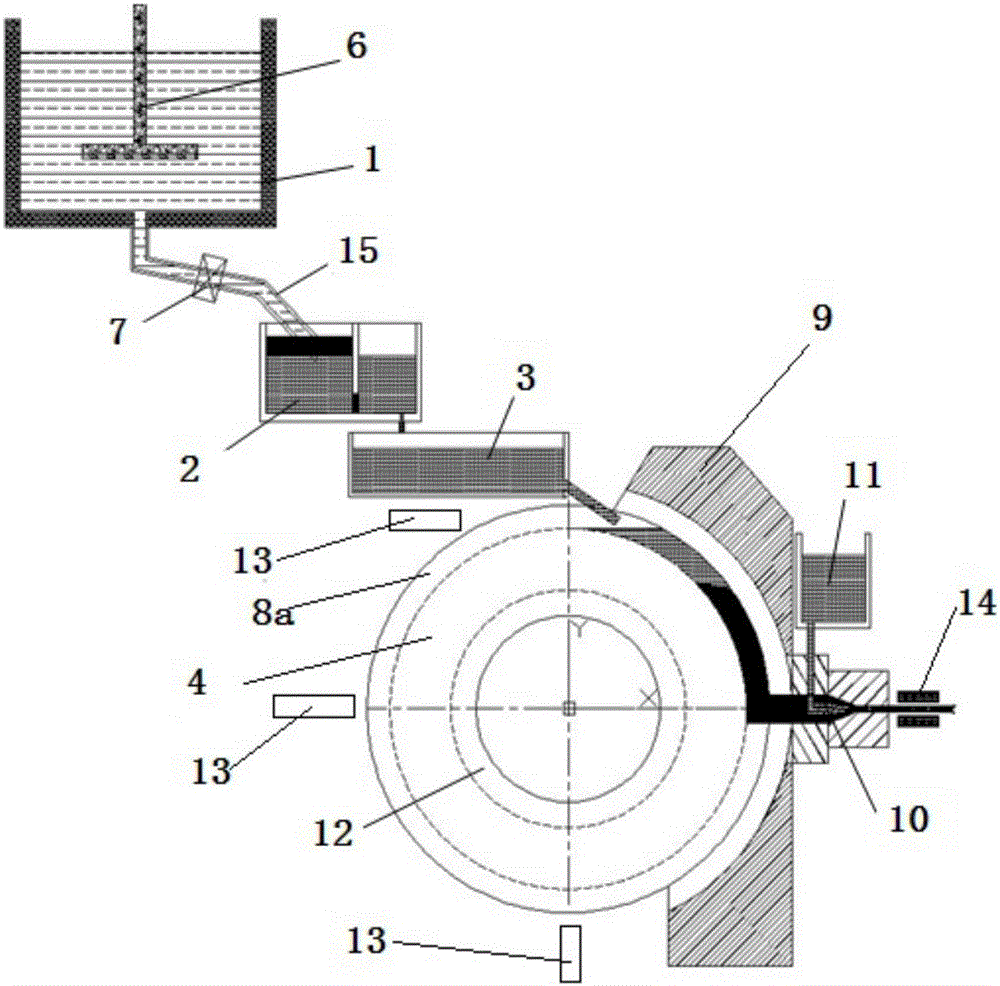

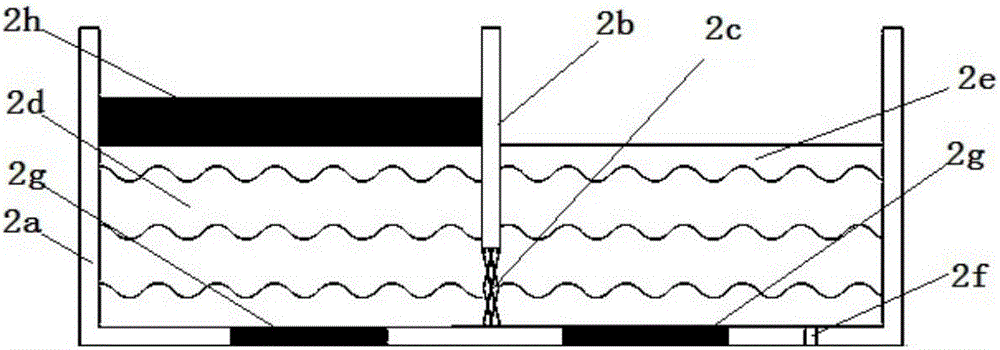

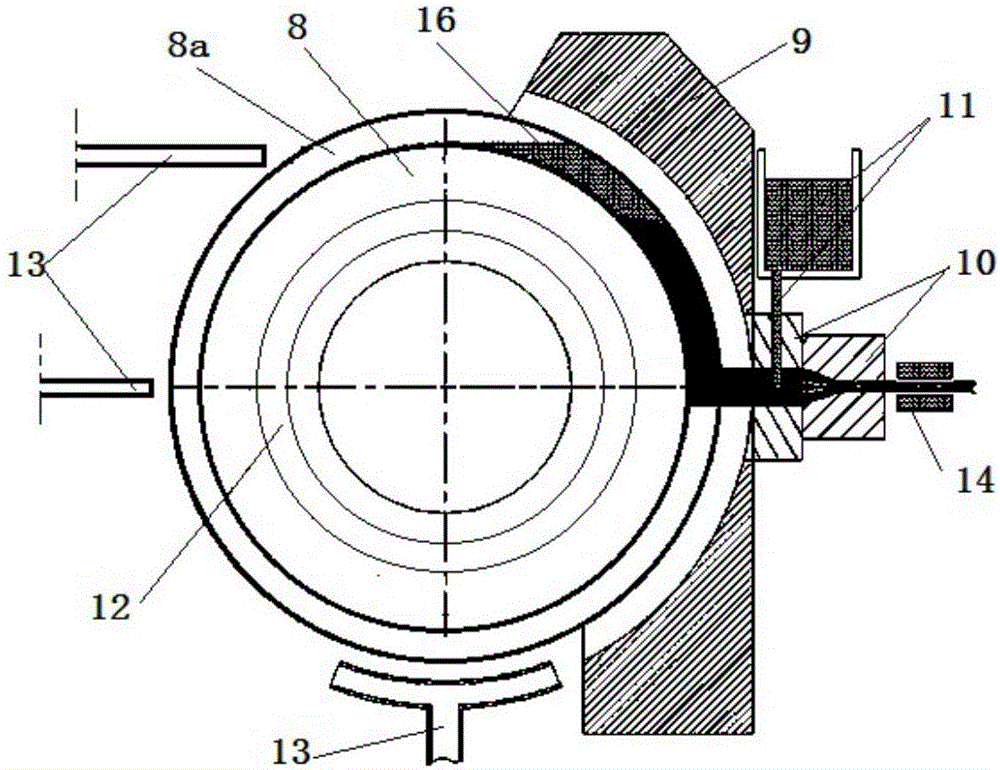

[0016] Such as figure 1 The shown cored solder bar continuous casting and extrusion processing system includes a rotary ventilating purification furnace 1 , a holding furnace 2 , a flow furnace 3 and a continuous extruder 4 arranged in sequence. The rotary ventilation purification furnace is provided with a rotatable and movable graphite rotor 6 which is fed with nitrogen or hexachloroethane. A flow control valve 7 is provided on the pipeline 5 where the molten metal flows from the rotary ventilation purification furnace 1 into the holding furnace 2 , and the pipeline 5 is covered with an insulation layer 15 . The holding furnace 2 is as figure 2 As shown, it includes a tank body 2a containing molten metal, a vertical baffle plate 2b set in the middle of the tank body suspended at the bottom, and a filter screen 2c arranged under the baffle plate. The baffle plate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com