Flexible circuit board

A flexible circuit board technology, applied in the direction of circuits, printed circuit parts, electrical components, etc., can solve the problems of punching offset, material breaking, and insufficient tensile strength of flexible circuit boards, and achieve good resistance The effect of tensile strength and optimum process cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

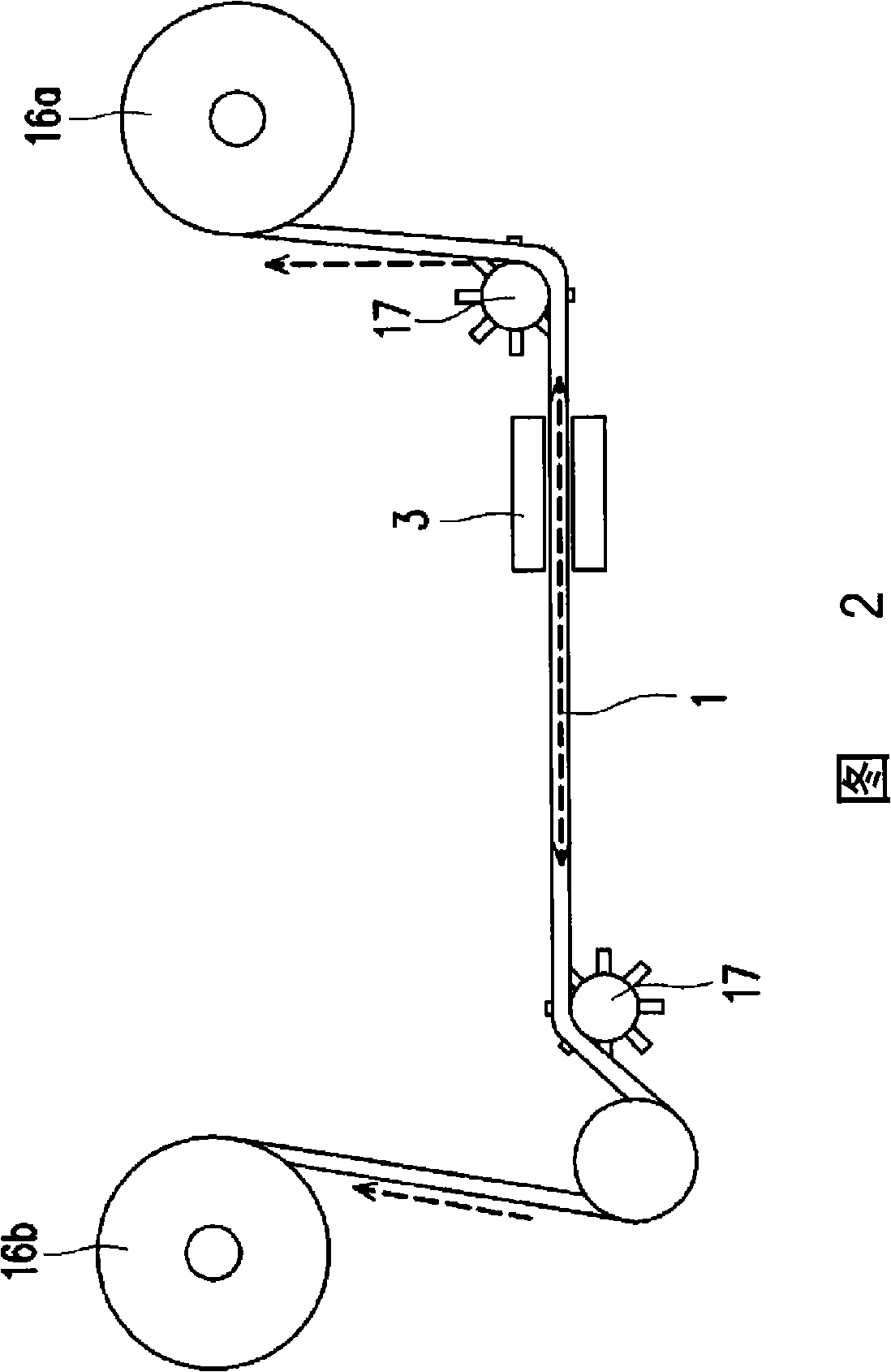

[0021] The flexible circuit board using the film-on-chip package will be described below as an embodiment. However, as mentioned above, in addition to film-on-chip packaging, tape-and-reel automatic bonding also includes tape-on-reel packaging. Therefore, the technical contents disclosed in the following embodiments are not limited to the chip-on-film packaging, but can also be applied to tape-on-reel packaging or other possible occasions.

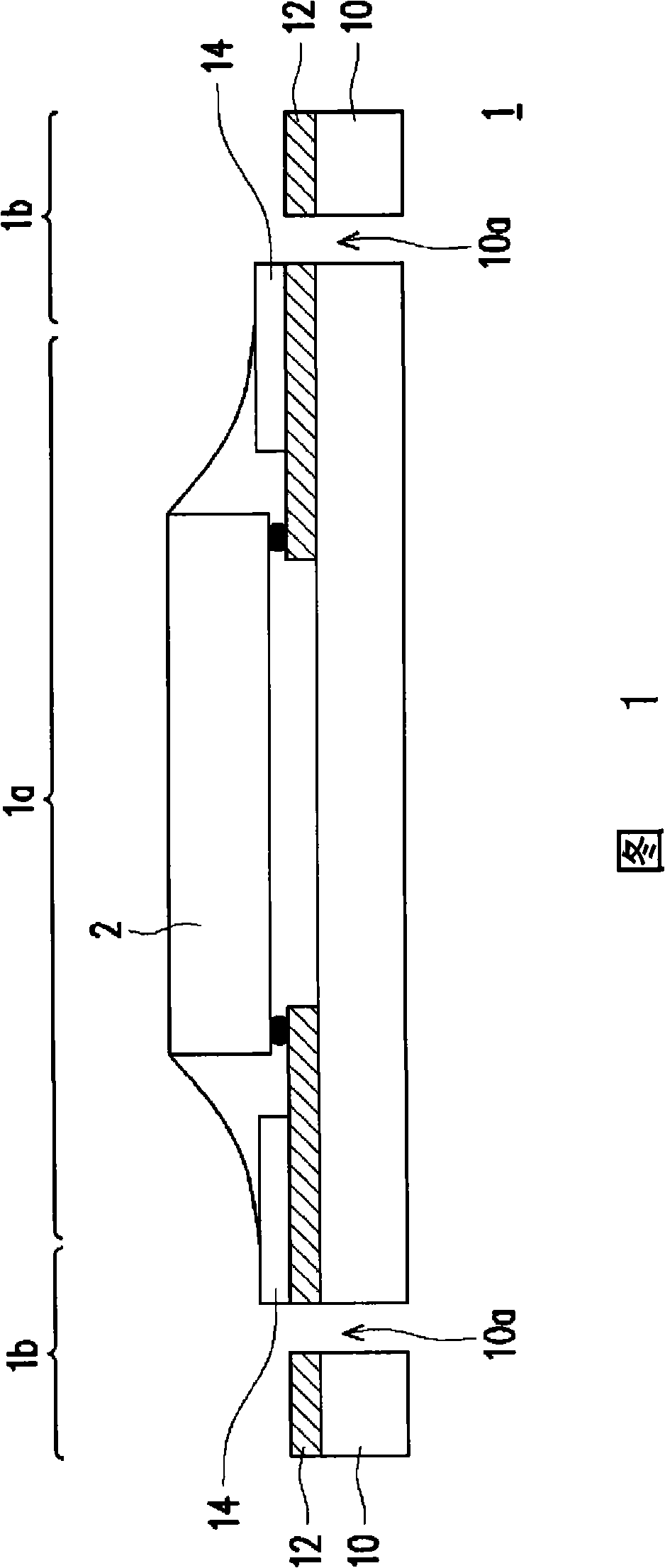

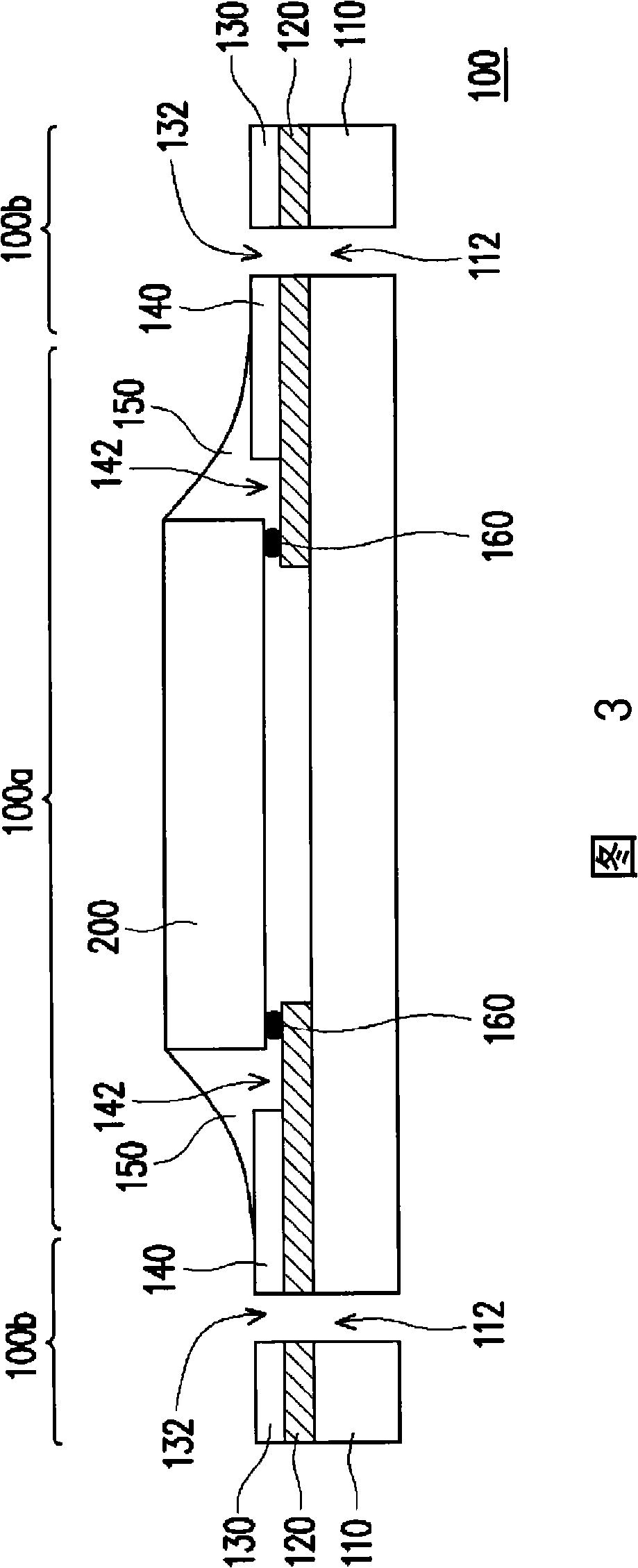

[0022] 3 is a schematic cross-sectional view of a chip disposed on a flexible circuit board according to an embodiment of the present invention, Figure 4 It is a top view of the flexible circuit board shown in FIG. 3 . It must be explained here that in order to clearly show the structure of the surface of the flexible circuit board, Figure 4 The chip and other possible components in FIG. 3 are omitted.

[0023] Please refer to Figure 3 together with Figure 4 , in this embodiment, the flexible circuit board 100 has a packaging area 100a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com