Rubbish smashing device for environment protection

A garbage crushing and environmental protection technology, applied in cleaning methods and utensils, cleaning methods using tools, grain processing, etc., can solve the problems of shortening the service life of the device, not being able to play a protective role, and breaking materials, so as to reduce labor costs, It is convenient for automatic maintenance and avoids the effect of splashing and hurting people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

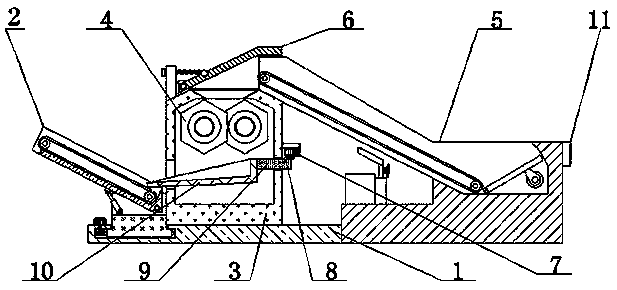

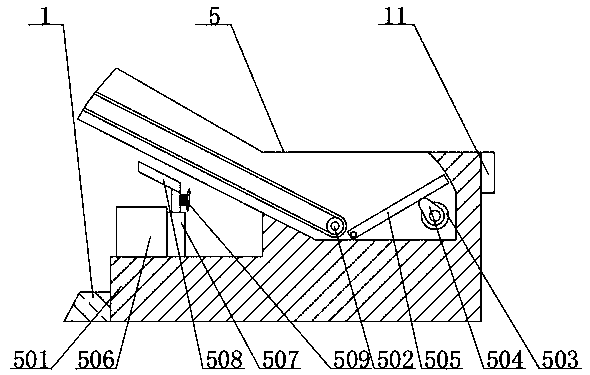

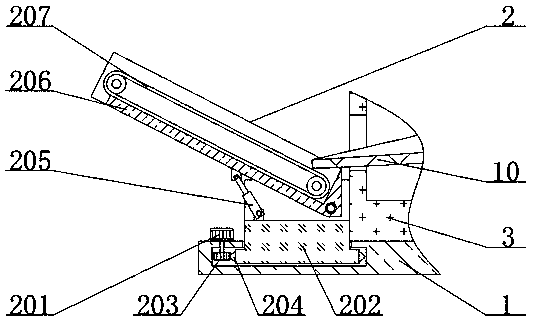

[0030] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the present invention provides a technical solution:

[0031]A garbage crushing device for environmental protection, comprising a support base 1, a discharge device 2 is provided on the left side of the top of the support base 1, and the discharge device 2 includes a second motor 201, a rotating seat 202, a gear 203, a gear ring 204, a first motor Telescopic rod 205, fixed frame 206 and first conveyor 207, the left side of support base 1 top surface is fixedly connected with second motor 201, and the main shaft of second motor 201 runs through support base 1, the main shaft of second motor 201 and support base 1 rotation connection, the right side of the second motor 201 is provided with a rotation seat 202, and the rotation seat 202 runs through the support base 1, the rotation base 202 is connected with the support base 1 in rotation, the main shaft end of the second motor 201 is fixedly connected wit...

Embodiment 2

[0035] In embodiment 2, the same part as embodiment 1 will not be repeated. The difference is that the right end of the inner rod of the second electric telescopic rod 507 is fixedly connected with a fan 509. When crushing wet garbage, the fan 509 will quickly The second conveyor 502 after the scraping treatment is air-dried to prevent the second conveyor 502 from being corroded by attached moisture vapor and sewage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com