Electrostatically-driven micro-clamp

An electrostatic actuation, micro-clamping technology, applied in the direction of chucks, manipulators, program-controlled manipulators, etc., can solve the problems of difficult to meet the requirements of fine operation, difficult to control the clamping force, inconvenient movement, etc., and achieve the clamping range. Large, easy to move, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

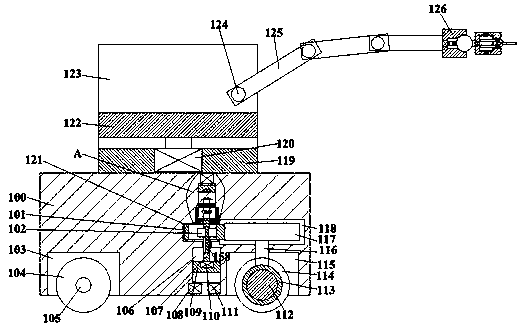

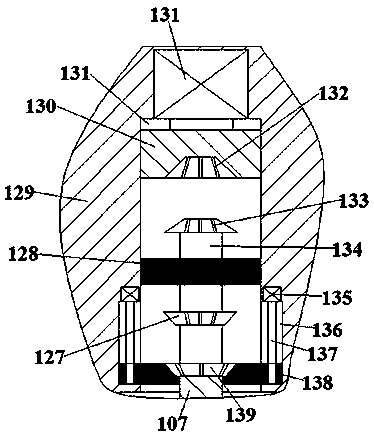

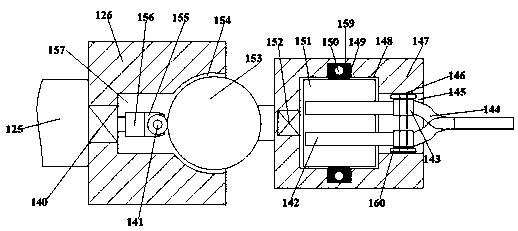

[0017] Such as figure 1 , figure 2 and image 3 As shown, the present invention is described in detail. For the convenience of description, the orientations mentioned below are now stipulated as follows: figure 1The up, down, left, right, front and back directions of the projection relationship are consistent. An electrostatically actuated micro gripper of the present invention includes a vehicle seat 100 and an operating body 119 arranged on the top end surface of the vehicle seat 100, and the bottom end surface of the vehicle seat 100 There are four centrally symmetrical grooves 103 with downward openings inside, and the front and rear two grooves 103 at the left end are rotated and connected with an axle 105 extending forward and backward. Inside the rear wheel 104, the top of the groove 103 at the right end is provided with a first cavity 118, the inner wall of the left end of the first cavity 118 communicates with a second cavity 121, and the bottom of the second cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com