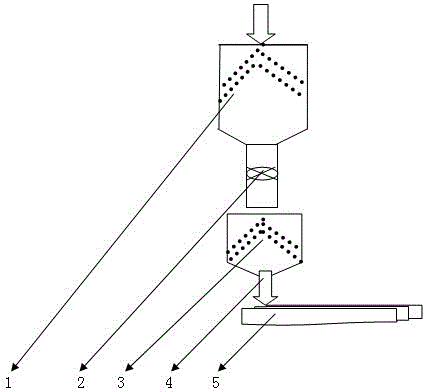

Control system for conveying and metering of granules

A technology of control system and granular materials, which is applied in the field of control system, can solve problems such as the inability to open the blanking baffle, the stoppage of the production line when the material is cut off, and the unreliable suction of the solenoid valve, so as to save downtime, prevent accidents, and perfect reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

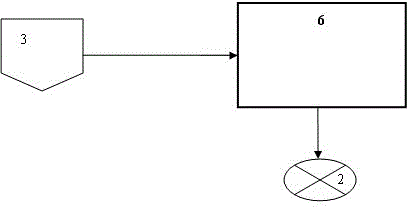

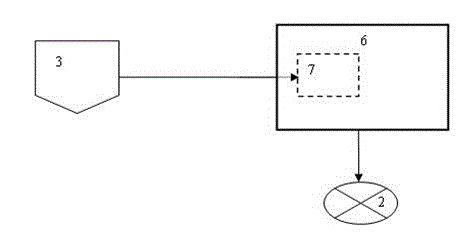

[0019] Establish a pulse timer in Siemens S7-300 PLC programming software to form a rectangular pulse generator.

[0020] a. On the output contact of the original command M0.0, establish two parallel "pulse timers SP" in series, namely T0 and T1, where T0 and T1 are connected in series with T1' and T0' normally closed contacts respectively, in order to interlock with each other.

[0021] b. Establish the T0 output point as the control output point of the blanking baffle. The pulse generator is then established.

[0022] When T0 is set to 5s and T1 is set to 1s, if the weighing bin reaches the lower limit, a high level "1" will be output, and a positive edge will occur on the logic bit of the pulse timer "T0", and the timing will start for 5 seconds, while T1 Because the T0' interlock does not work, after 5 seconds, T0 stops working, and the feeding baffle resets; at this time, the T0' normally closed contact is closed. If the weighing of the metering bin does not reach the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com