Blown film production line auger automatic feeding device

A blown film and automatic feeding technology, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of high production energy consumption, affecting product quality, and dust environmental pollution, so as to save energy consumption and improve one-time pass rate, the effect of solving environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

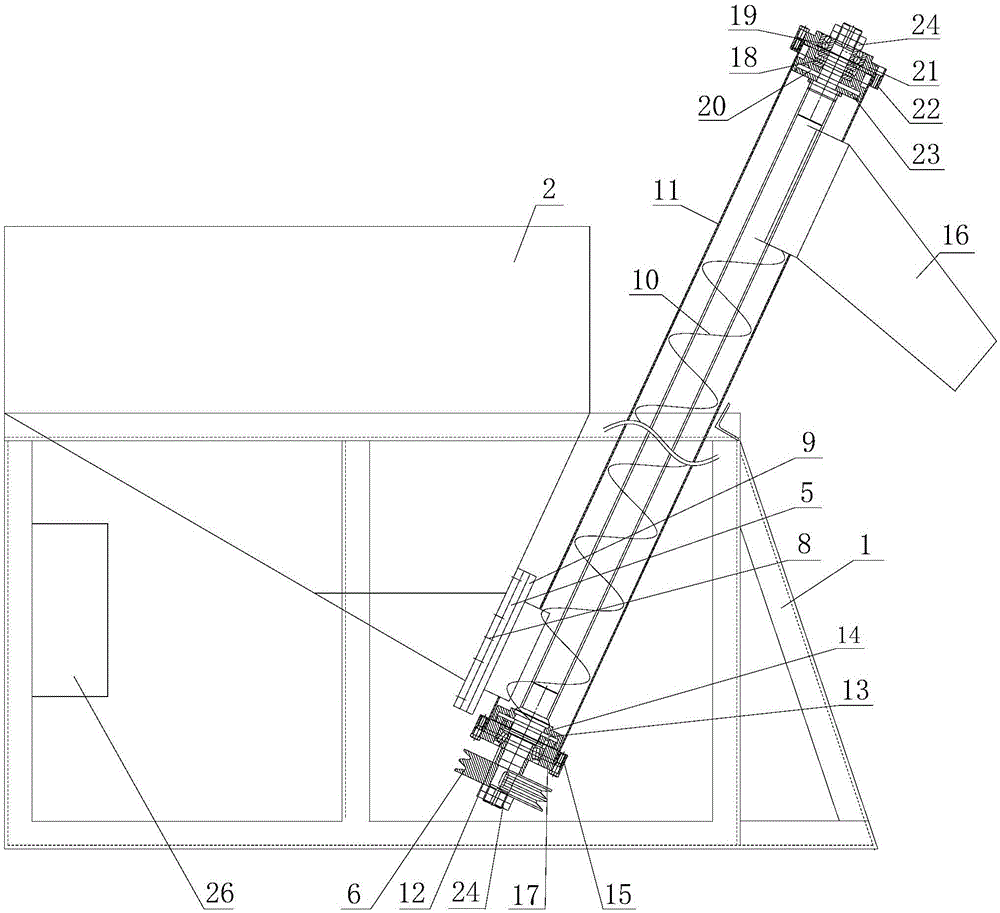

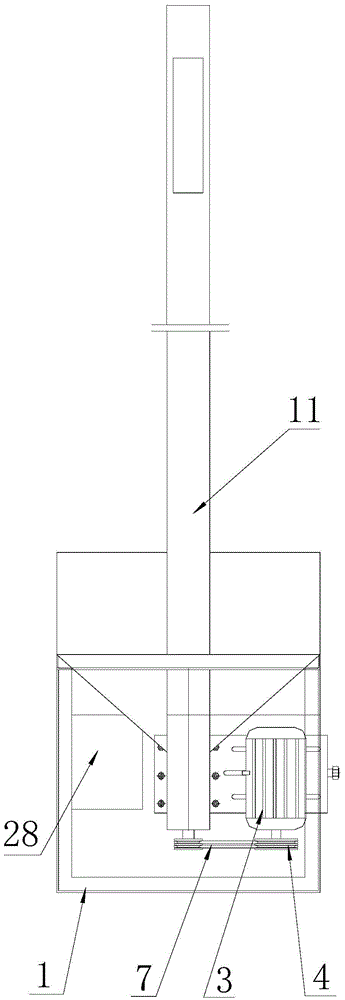

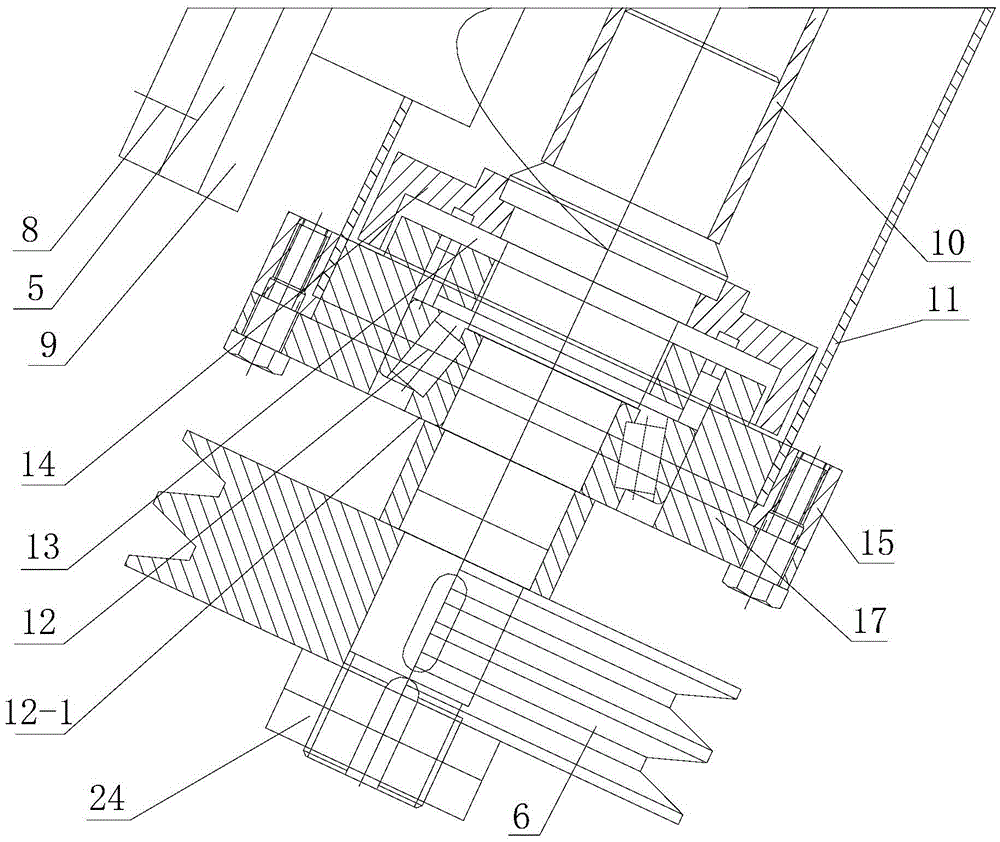

[0024] see Figure 1-Figure 4 , the blown film production line auger automatic feeding device, including a storage hopper 2 fixed on the frame 1, also includes an auger 10 for conveying materials located in the corresponding discharge port 2-1 position in the storage hopper, through The motor connecting plate 5 is fixedly mounted on the motor 3 outside the storage hopper, and the feeding start electronic feedback device 26 and the feeding closing electronic feedback device 27 are arranged on the extruder hopper. The exterior of the auger is fixed with an outer wall 11 made of metal material, and an auger outlet 16 is arranged on the upper part of the outer wall 11. In this embodiment, the outer wall of the auger is made of stainless steel. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com