Material conveying and spraying device for 3D printing

A 3D printing and jetting device technology, applied in 3D object support structures, additive manufacturing, manufacturing tools, etc., can solve the problems of disjointed and inconvenient adjustment of advanced consumables, and achieve the adjustment of jetting position, avoid material breakage, and increase contact The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

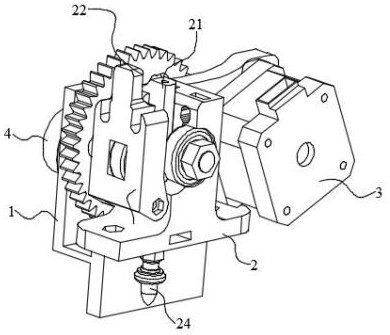

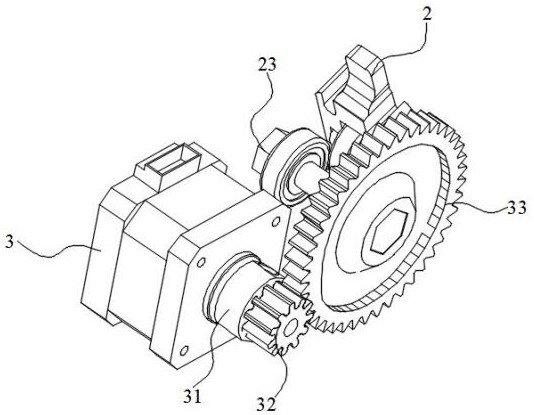

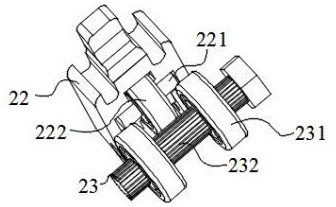

[0021] Embodiment 1: The present invention provides a material delivery and injection device for 3D printing, which includes an installation main frame 1 and a fixing frame 2 fixed at one end of the installation main frame 1, and one side of the installation main frame 1 is equipped with an installation and removal structure 4. A motor 3 is installed on one side of the installation main body frame 1, and a rotating shaft 31 is installed on the output end of the motor 3 through a coupling, and a driving gear 32 is fixed on the end of the rotating shaft 31 away from the motor 3, and the driving gear 32 is meshed with a driven gear 33, the center of the driven gear 33 is provided with a transmission shaft 23, both ends of the transmission shaft 23 are sleeved with a driving disc 231 in the axial direction, and one side of the fixed frame 2 A short guide tube 21 is fixed, and the bottom end of the fixed frame 2 is provided with a spray head 24; and one end of the motor 3 is install...

Embodiment 2

[0022] Embodiment 2: The present invention provides a material delivery and injection device for 3D printing, including an installation main frame 1 and a fixing frame 2 fixed at one end of the installation main frame 1, and an installation and disassembly structure is installed on one side of the installation main frame 1 4. A motor 3 is installed on one side of the installation main body frame 1, and a rotating shaft 31 is installed on the output end of the motor 3 through a coupling, and a driving gear 32 is fixed on the end of the rotating shaft 31 away from the motor 3, and the driving gear 32 is meshed with a driven gear 33, the center of the driven gear 33 is provided with a transmission shaft 23, both ends of the transmission shaft 23 are sleeved with a driving disc 231 in the axial direction, and one side of the fixed frame 2 A short guide tube 21 is fixed, and the bottom end of the fixed frame 2 is provided with a spray head 24; and one end of the motor 3 is installed...

Embodiment 3

[0023] Embodiment 3: The present invention provides a material delivery and injection device for 3D printing, including an installation main frame 1 and a fixing frame 2 fixed at one end of the installation main frame 1, and an installation and disassembly structure is installed on one side of the installation main frame 1 4. A motor 3 is installed on one side of the installation main body frame 1, and a rotating shaft 31 is installed on the output end of the motor 3 through a coupling, and a driving gear 32 is fixed on the end of the rotating shaft 31 away from the motor 3, and the driving gear 32 is meshed with a driven gear 33, the center of the driven gear 33 is provided with a transmission shaft 23, both ends of the transmission shaft 23 are sleeved with a driving disc 231 in the axial direction, and one side of the fixed frame 2 A short guide tube 21 is fixed, and the bottom end of the fixed frame 2 is provided with a spray head 24; and one end of the motor 3 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com