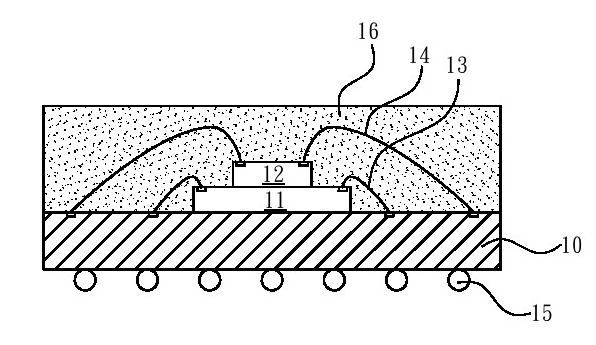

Ball grid array (BGA) package structure

A ball grid array and structure technology, which is applied in semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve problems such as unfavorable wire material costs, punching defects, and reducing the overall package length, width, and height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

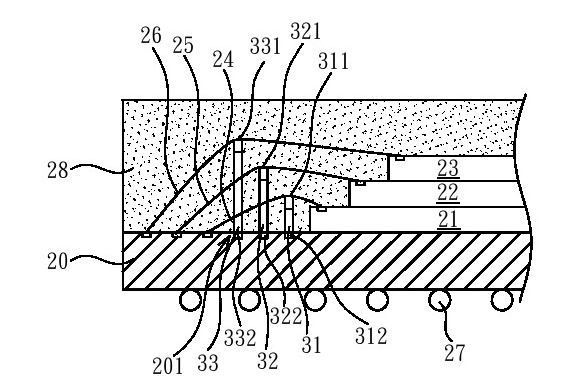

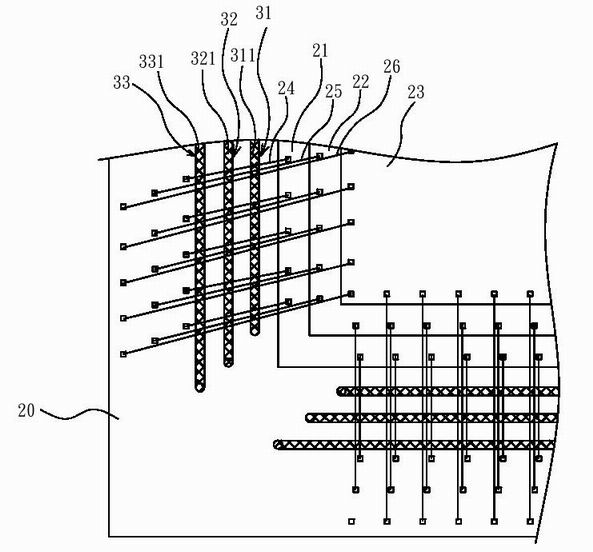

[0030] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the invention may be practiced. Furthermore, the directional terms mentioned in the present invention, such as "up", "down", "front", "rear", "left", "right", "inside", "outside" or "side", etc., Only refer to the directions of the attached drawings. Therefore, the directional terms used are for describing and understanding the present invention, not for limiting the present invention.

[0031] The present invention is mainly applied to a ball grid array (BGA) package structure with stacked dies, wherein the BGA package structure preferably has three or more chips and three or more layers of wires; the ball grid The length and width dimensions of the array package structure are preferably equal to or greater than 21×21 mm (millimeters); and the total number of wires on each side of the ball grid array package structure is preferably equal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com