Feeding device capable of preventing material breakage and used for 3D printing

A 3D printing and raw material technology, applied in the field of 3D printing, can solve problems such as affecting the finished product and breaking, and achieve the effect of preventing material breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will now be described in further detail with reference to the drawings. These figures are schematic diagrams, which will be described only in a schematic manner, and therefore it only shows the configurations related to the present invention.

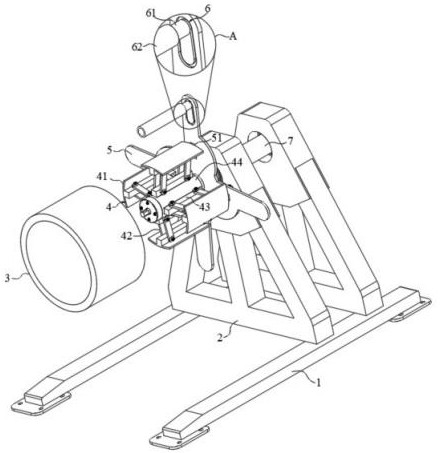

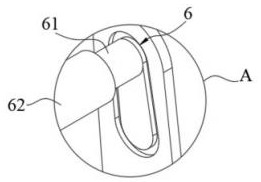

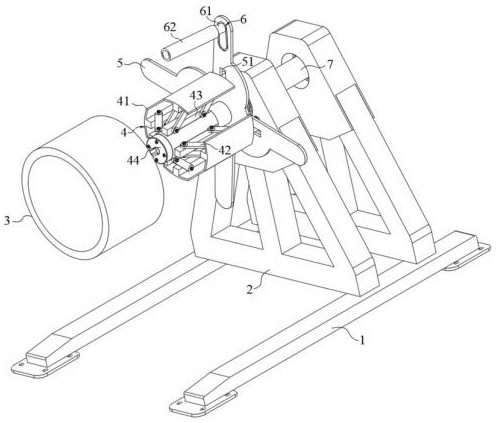

[0030] See figure 1 , figure 1 It is a first state perspective view of a preferred embodiment of a 3D printing sheet of the present invention; see figure 2 , figure 2 In the present invention figure 1 The magnification structure diagram of the preferred embodiment of the in-A-A; Figure 1-2 As shown, the present invention discloses a 3D printing of a disconnect, including: base 1 and two parallel support bracket 2 on one side of the top of the base 1; the support frame 2 includes a disposed in place The material plate 5 on the outer wall of the support frame 2 is disposed at the outer wall of the material plate 5, which is adapted to penetrate the lubrication portion 8 in the middle of the material plate 5, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com