Rim charge winding device of slitting unit

A technology of a coiling device and unit, which is applied in the direction of coiling strips, thin material handling, transportation and packaging, etc., can solve the problems of easy burnout, material breakage, etc., to prevent material breakage, simple control circuit, and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

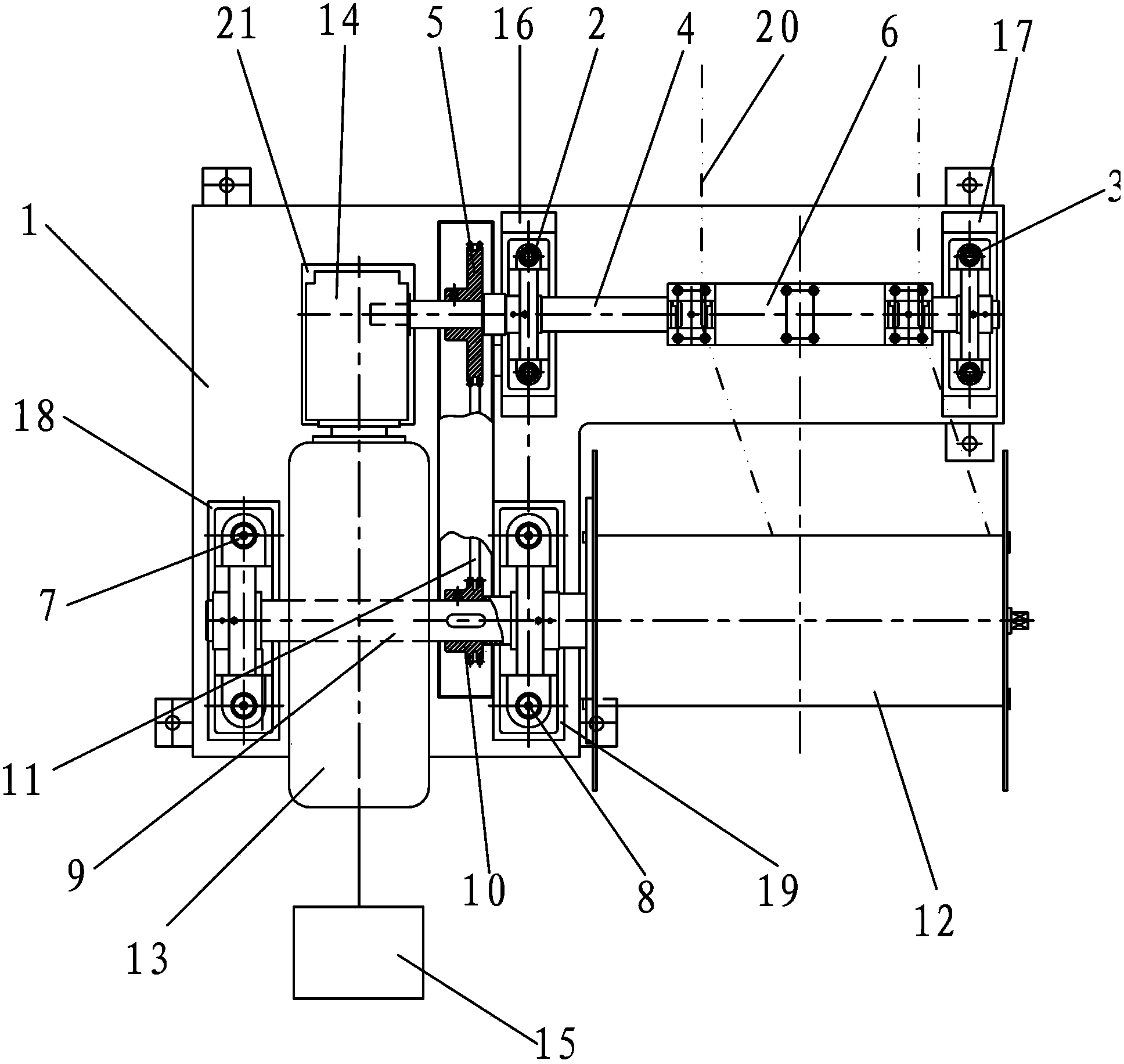

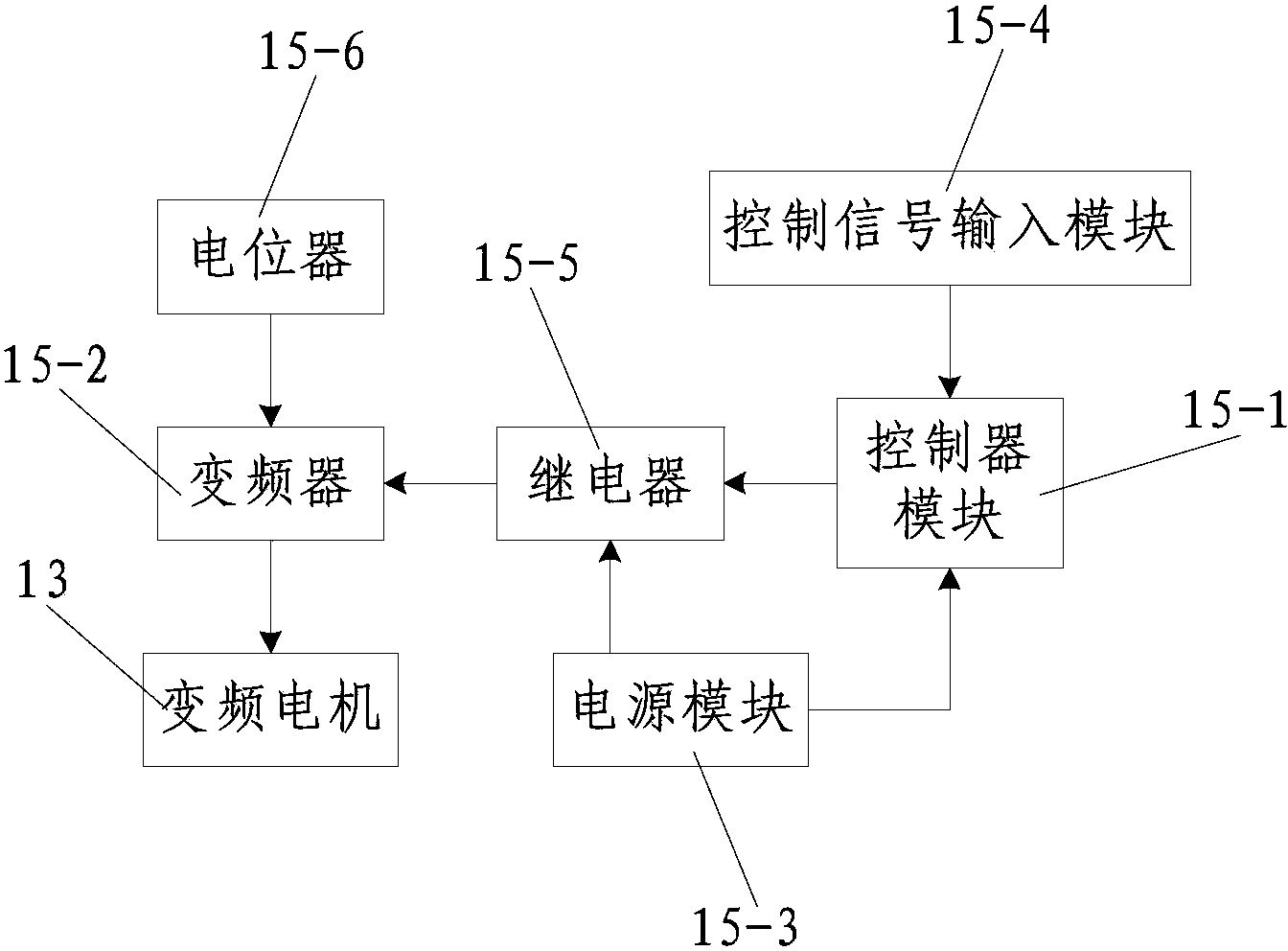

[0030] Such as figure 1 As shown, the present invention includes a base 1, a material guide mechanism, a winding mechanism, a power mechanism and a power control system 15, and the power mechanism includes a frequency conversion motor 13 and a speed reducer 14 connected with the frequency conversion motor 13, and the material guide mechanism It includes a first bearing with a seat 2 and a second bearing with a seat 3 arranged at intervals on the base 1, and a screw 4 installed on the first bearing with a seat 2 and the second bearing with a seat 3, the The shaft end of the lead screw 4 extends into the reducer 14, and a first sprocket 5 is installed on a section of the lead screw 4 between the reducer 14 and the first bearing with seat 2, which is located in the first A guide tube 6 that can swing left and right on the leading screw 4 is installed on a section of the leading screw 4 between the bearings with seat 2 and the second bearing with seat 3; The third belt seat beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com