Particle carrier band forming system and process

A molding process and carrier tape technology, applied in belts, packaging, other household appliances, etc., can solve the problems of sudden change of hole position, deformation of carrier tape receiving direction, economic loss of enterprises, etc., to reduce heat loss and avoid user complaints , the effect of speeding up the drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

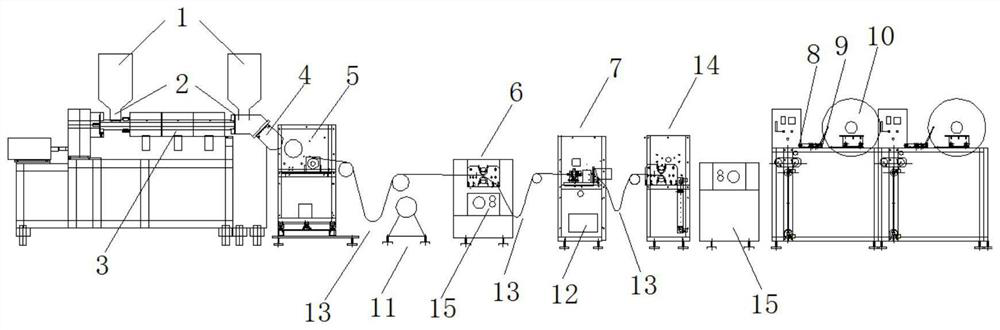

[0069] see Figure 1-14 , the present invention relates to a particle carrier tape forming system and process, the process steps are:

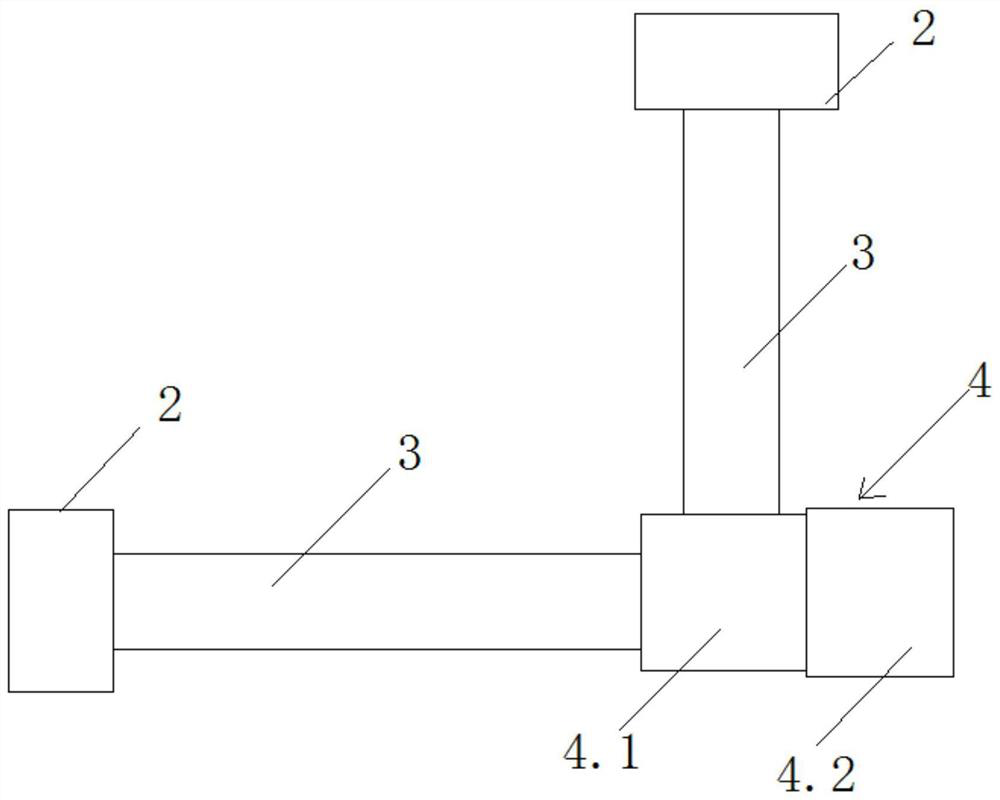

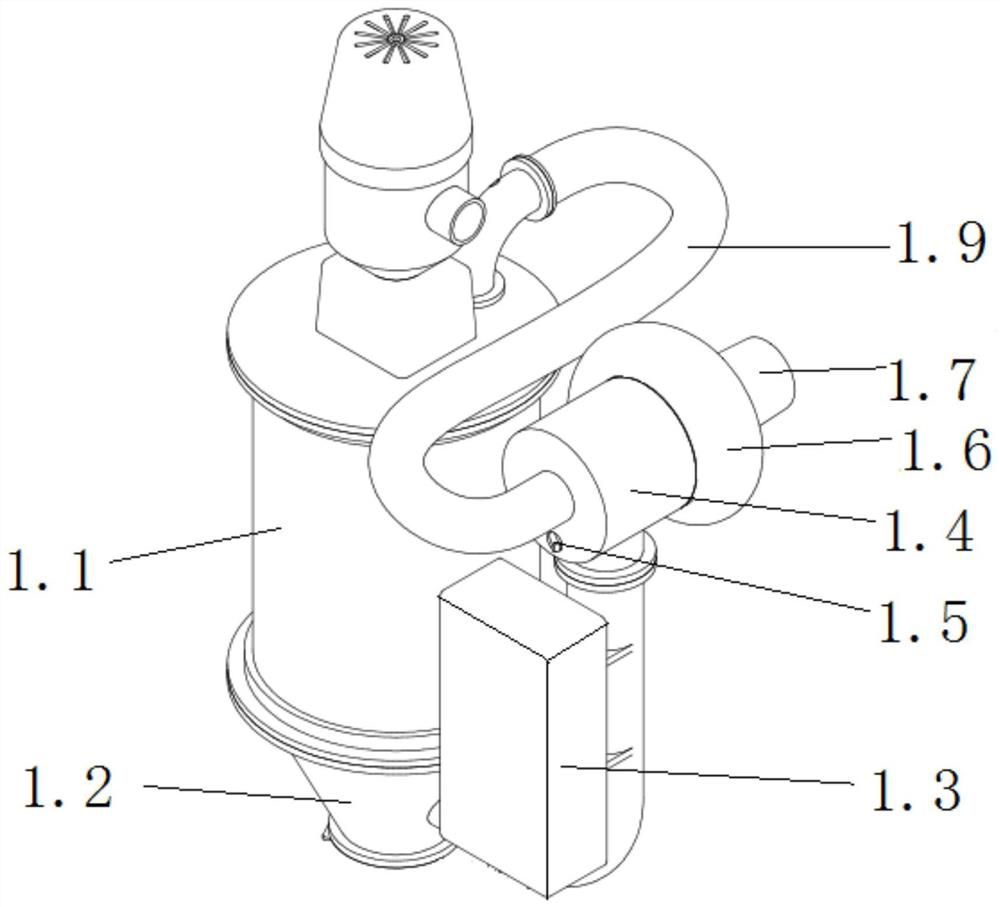

[0070] Step 1, batching: After the master batch A and master batch B are heated and dried by the hot air return system 1, they are input into two screw extruders 3 through two feeding mechanisms 2, and the two screw extruders 3 are respectively Masterbatch A and masterbatch B are extruded into composite extrusion die 4;

[0071] Step 2, forming: the composite extrusion die head 4 laminates the masterbatch A and masterbatch B and transports them to the molding mechanism 5 for molding, that is, the composite extrusion die head 4 presses out the sheet-like carrier tape, and the molding mechanism 5 Continuous vacuum adsorption molding on the carrier tape to form a box cavity;

[0072] Step 3, punching: the punching module 7 punches the carrier tape;

[0073] Step 4, striping: the stripping module 14 strips the carrier tape, and divides the carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com