High-magnesium low-heat portland cement clinker aggregate and preparation method thereof

A technology of Portland cement and cement clinker, applied in the field of cement, can solve problems such as unfavorable crack resistance of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

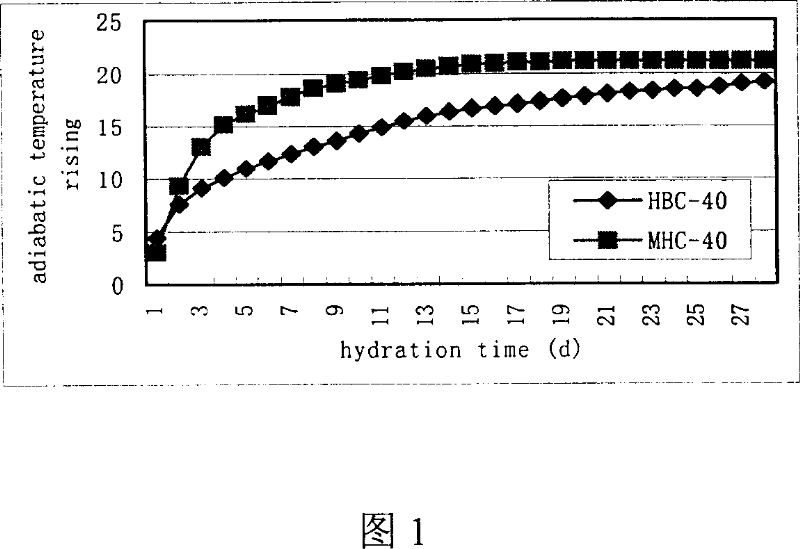

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

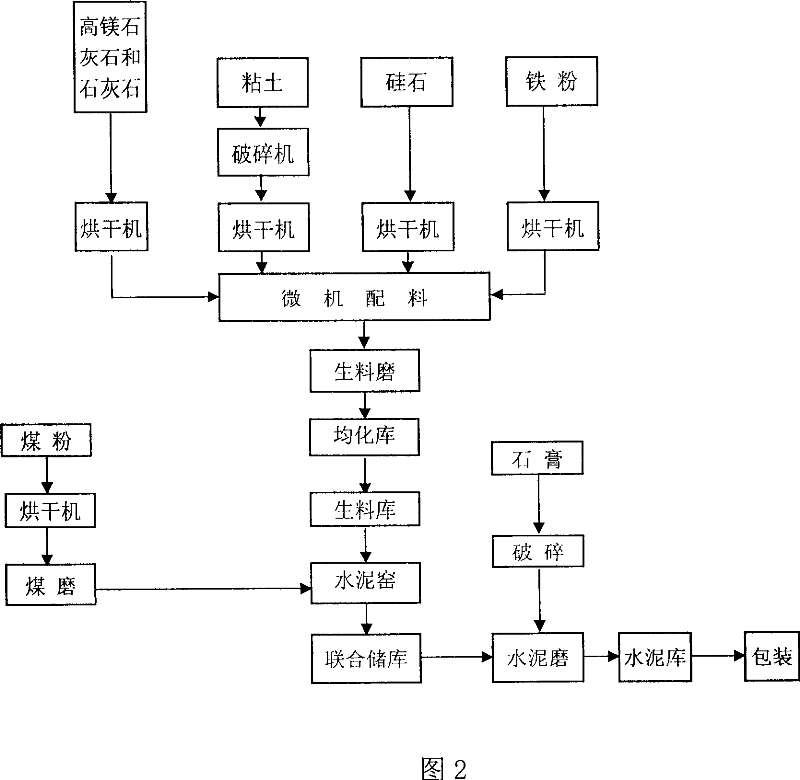

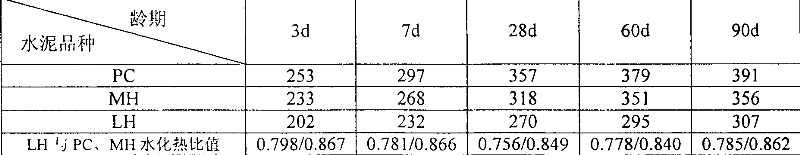

[0020] Embodiment 1: The proportioning is limestone: high-magnesium limestone: clay: iron powder: silica = 30.6: 45.9: 13.5: 4: 6 for batching. The chemical composition of raw materials is shown in Table 1, and the clinker composition, rate and mineral composition are shown in Table 1. Table 2. High-activity high-magnesium low-heat Portland cement clinker is produced by conventional methods (see Figure 2 production process) in a φ2.5×45m five-stage cyclone preheater kiln. The clinker is fine and uniform, with good granulation and no Pulverization phenomenon, the clinker is mixed with gypsum as a retarder to produce high-magnesium low-heat Portland cement. The physical performance test results are shown in Table 3.

[0021] raw material

[0022] Clinker chemical composition, %

[0023]

Embodiment 2

[0024] Embodiment two: adopt proportioning to be limestone: clay: iron powder: red mud: silica=69.3: 9.3: 1.5: 14: 5.9 carry out batching, produce the high-activity high-magnesium low-heat portland cement with the method for embodiment one Clinker, its clinker composition, rate value and mineral composition are shown in Table 4.

Embodiment 3

[0025] Embodiment three: adopt proportioning to be high-magnesium limestone: fly ash: iron powder: yellow sand=78.2: 6.1: 3.6: 12.1 carry out batching, produce the highly active high-magnesium low-heat Portland cement cooked by the method of embodiment one See Table 4 for clinker composition, ratio and mineral composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com