Double-insurance pneumatic clamping chuck

A double insurance and chuck technology, applied in the direction of chucks, clamping, positioning devices, etc., can solve the problems of insufficiently stable jaw stretching and unsteady movement of a single cylinder, and achieve reduced length, reduced thickness, and reduced effect of distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Below in conjunction with accompanying drawing, the present invention is described in further detail:

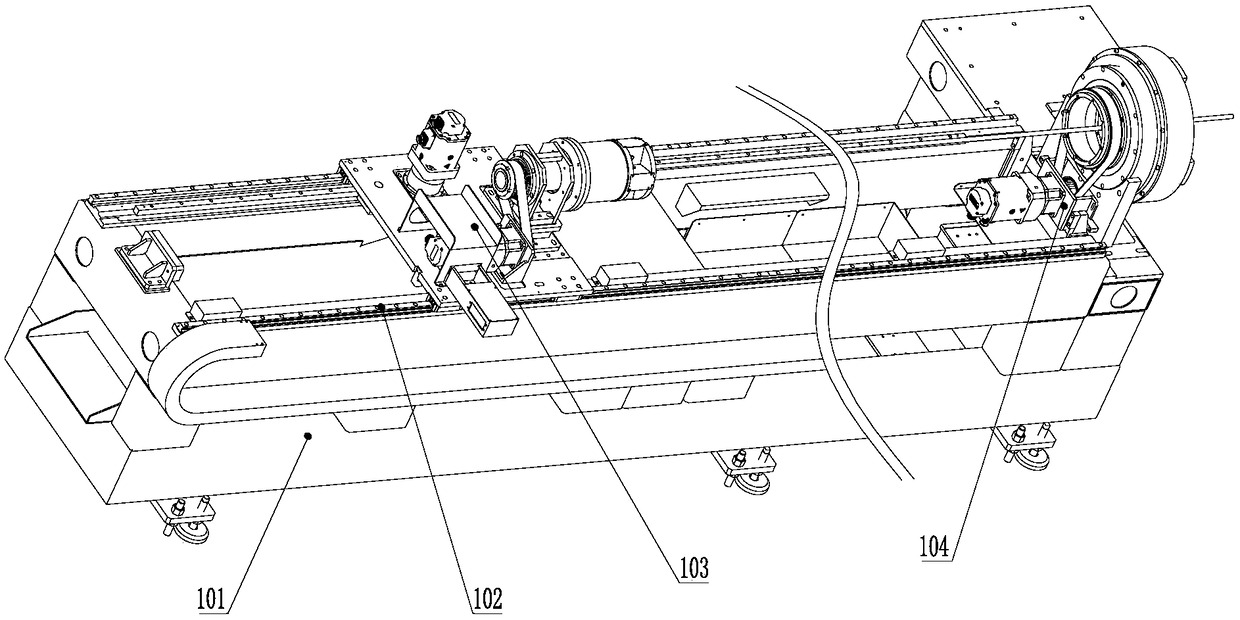

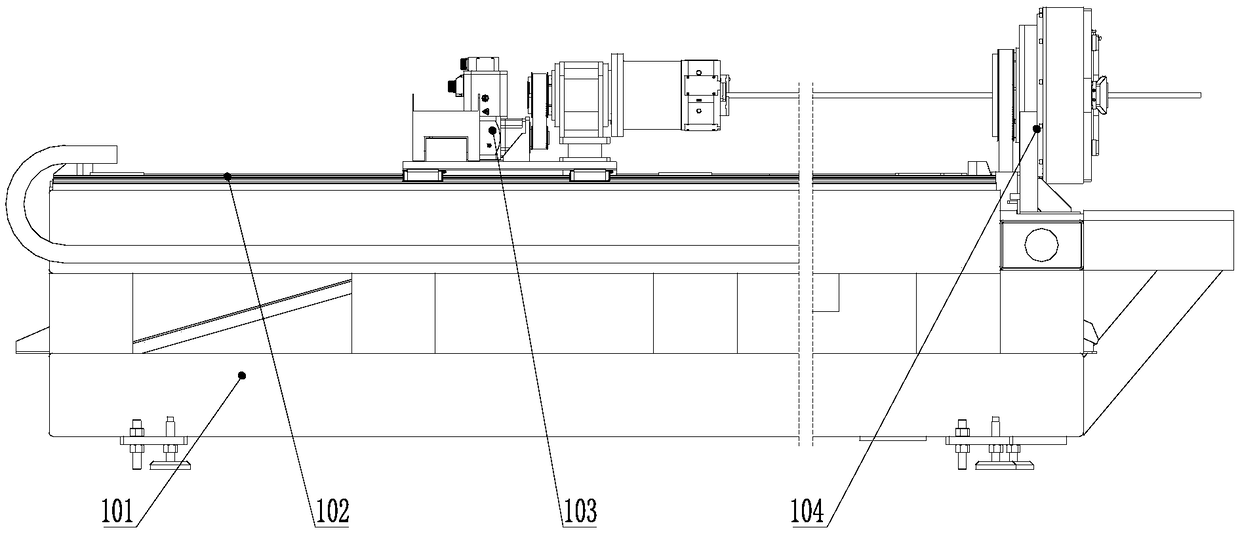

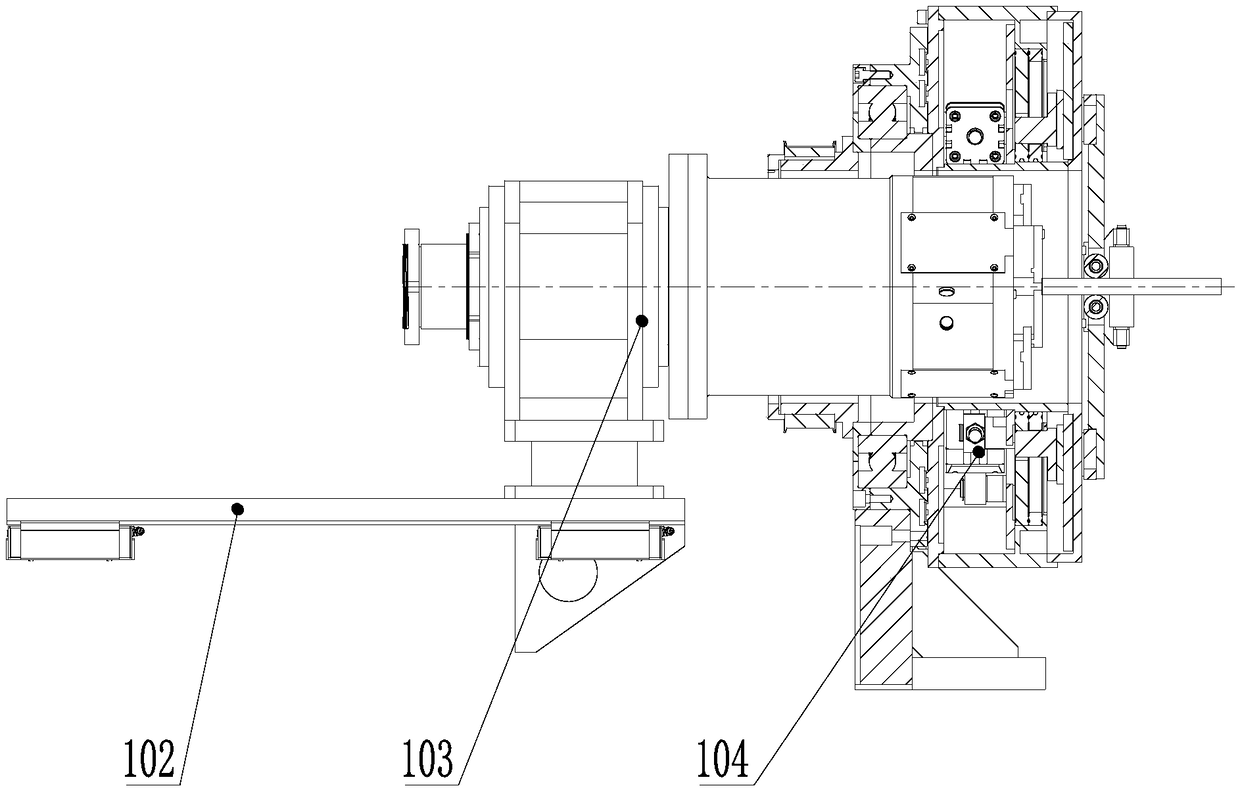

[0054] Such as Figure 1-3 As shown, a cutting machine for saving tailings includes a frame 101, a first guide rail 102, a front chuck 104 and a rear chuck 103, the top surface of the frame 101 is provided with a first guide rail 102, and the The first guide rail 102 is provided with a rear chuck 103, and the rear chuck 103 can reciprocate along the direction of the first guide rail 102. The frame 101 at the end of the first guide rail 102 is provided with a front chuck 104. The chuck 104 and the rear chuck 103 are independently driven respectively and have the same rotating speed. The centers of the front chuck 104 and the rear chuck 103 are on the same axis, and the front chuck 104 is provided with Extending to the through hole inside the front chuck 104 , the rear chuck 103 can extend into the inside of the through hole of the front chuck 104 . The front chuck 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com