Integrity testing device for construction film material under action of force and thermal radiation and using method

A test device, heat radiation technology, applied in the field of building fire prevention and fire fighting and rescue, to achieve the effect of simple connection, strong applicability, and simple components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

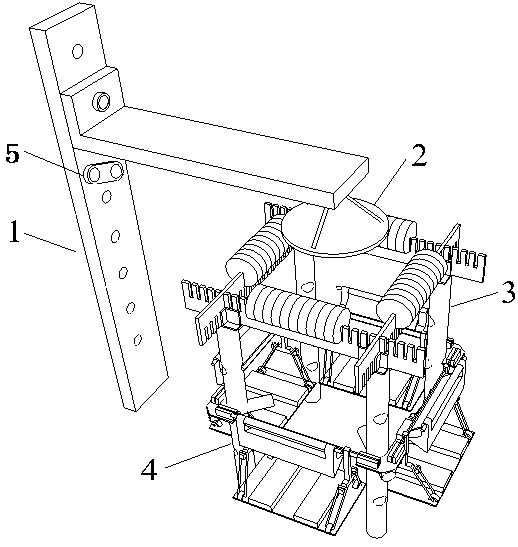

[0086] Such as Figure 1 to Figure 13 As shown, the complete performance test device of architectural membrane materials under the action of force and heat radiation includes a heat radiation source 2, a video recording device 5, a lifting device 1, a supporting device 3, and a loading device 4.

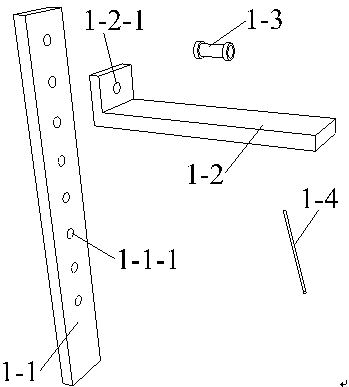

[0087] The lifting device 1 includes a column 1-1, an L-shaped joist 1-2, and a suspension wire I1-4.

[0088] Several bolt holes I1-1-1 are arranged at equal intervals on the column 1-1, the column body of the column 1-1 is fixed to the L-shaped joist 1-2, the bottom of the column 1-1 is fixed on the ground, and the three suspension wires I1-4 One end is respectively connected with the bottom surface of the long limbs of the L-shaped joist 1-2, and the other end is connected with the heat radiation source 2 respectively.

[0089] The video recording equipment 5 is fixed on the column body of the column 1-1.

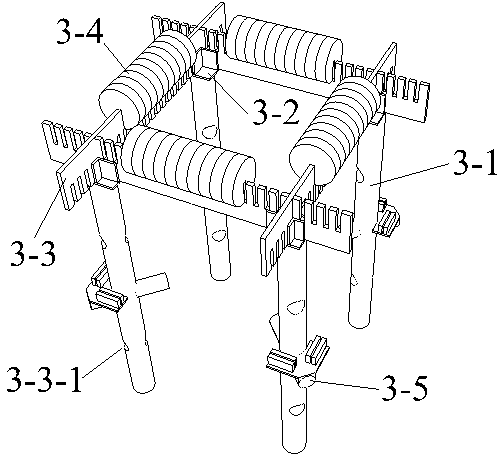

[0090] The supporting device 3 includes a short column 3-1, a fixed card...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com