Double-worktable exchanging mechanism of machining center

A technology of exchange mechanism and double worktable, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve problems such as inability to ensure the accuracy of machine tools, wear of positioning mechanisms, safety accidents, etc., to improve machining efficiency, Ensure accuracy and prevent inaccurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

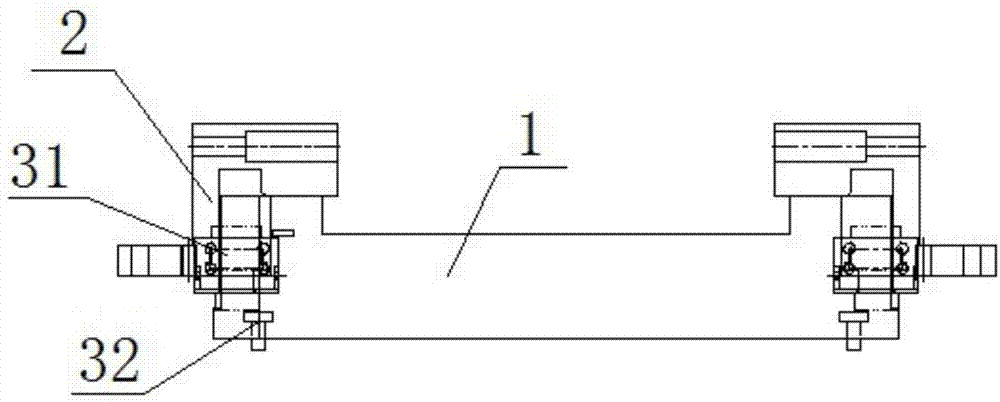

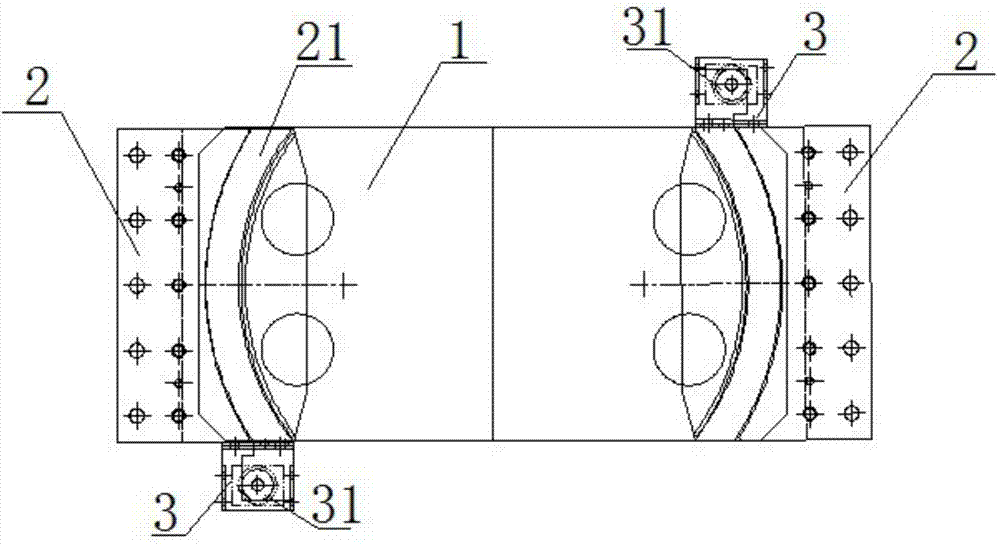

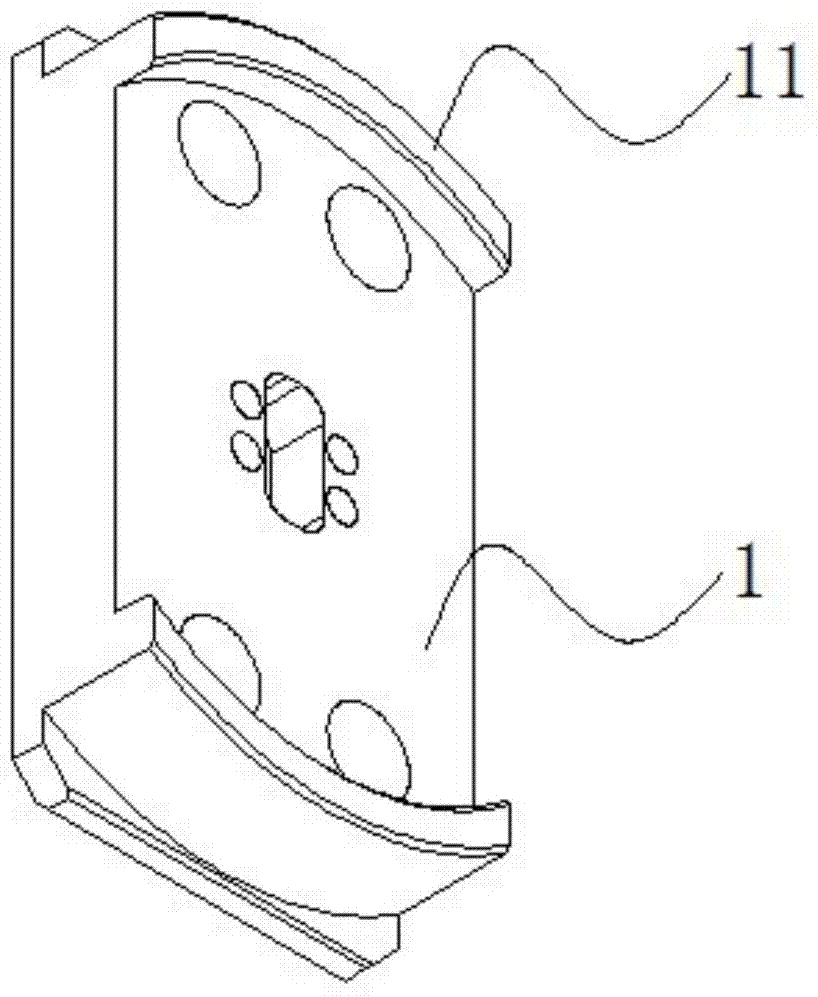

[0038] See Figure 1 to Figure 3 , the double workbench exchange mechanism of the machining center of the present invention includes a liftable base 1 and a workbench support device 2 above the base 1, and there are two workbench support devices 2; the exchange mechanism is also provided with a wireless positioning device 3 for wireless positioning The device 3 includes a model ZBRTE wireless positioning switch 31 and a positioning screw 32 produced by Schneider Electric Company. The wireless positioning switch 31 is fixedly installed on one side of the workbench supporting device 2, and the positioning screw 32 is correspondingly arranged on the base 1 below the wireless positioning switch 31. . The receiver matched with the wireless positioning switch is also produced by Schneider Electric Company, its model is ZBRRA, and the receiver is installed in the control system.

[0039] Preferably, there are two wireless positioning devices 3, and the two wireless positioning devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com