Novel cutter for horizontal turning lathe

A technology for horizontal lathes and cutting tools, which is applied in the direction of cutting tools, tool holders, and turning equipment used in lathes, and can solve problems such as the inability to process areas with small outer diameters, the inability to complete parts processing, and relatively large changes in outer diameters. , to achieve the effects of convenient processing, increased processing range and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below by means of the accompanying drawings and examples.

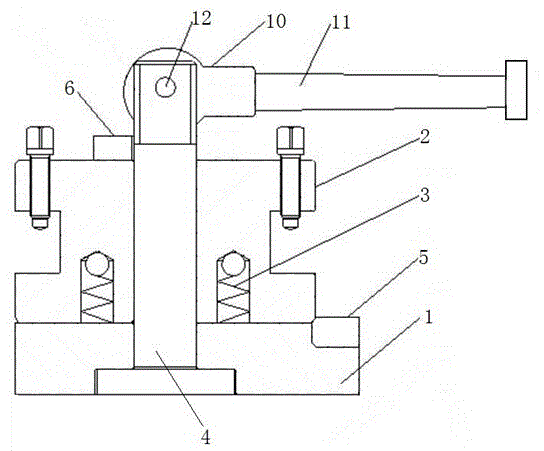

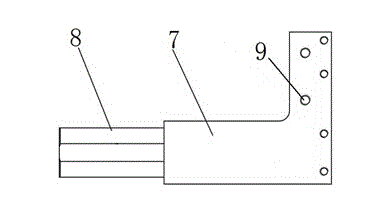

[0014] Such as figure 1 with figure 2 As shown, a novel horizontal lathe tool according to the present invention includes a tool holder and a cutter head; The frame 2 is provided with a spring 3, the base 1 and the mounting frame 2 are connected by a central connecting shaft 4, a locking mechanism is provided on the upper part of the central connecting shaft 4, and a locking mechanism is provided at the connection between the base 1 and the mounting frame 2. There is a positioning block 5, and an adjustment block 6 is arranged on the mounting frame 2 below the locking mechanism; It is arranged on one end of the knife handle 7, and the other end of the knife handle 7 is provided with a mounting hole 9; the locking mechanism includes a compression block 10, and a handle 11 fixedly connected with the compression block 10, in the The middle part of the pressing bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com