An all-round intelligent turning and edging system applied to circuit board processing

An all-round, circuit board technology, which is applied to machine tools, metal processing equipment, grinding machines, etc., which are suitable for grinding the edge of workpieces, can solve the problems of scattered structure of grinding devices, large footprint, inconvenient processing, etc., and achieve compact structure , easy transposition, ingenious design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

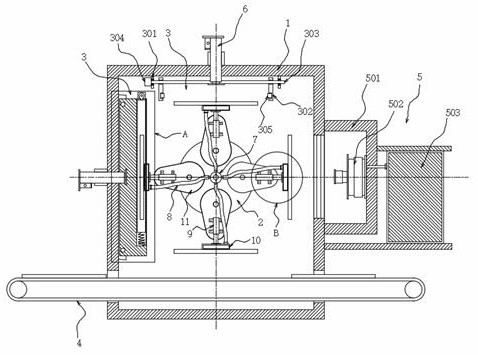

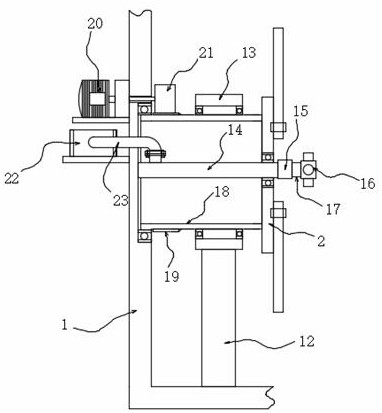

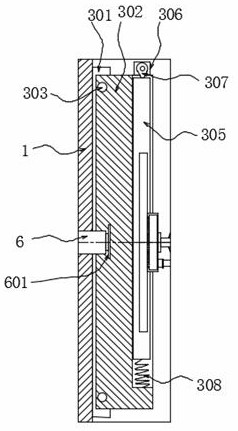

[0027] refer to Figure 1-4 , an all-round intelligent turning and edging system applied to circuit board processing, including:

[0028] Dustproof box 1;

[0029] Rotating mechanism, this rotating mechanism is arranged on the back side of dust-proof box 1, wherein, rotating mechanism comprises hollow rotating cylinder 18, the disk 2 that is fixedly arranged on one end of hollow rotating cylinder 18 and the drive mechanism that drives hollow rotating cylinder 18 to rotate, hollow rotating The other end of the cylinder 18 is rotated and fitted on the inner back of the dustproof box 1;

[0030] Suction mechanism, the suction mechanism is arranged on the rotating mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com