Workbench with cross-shaped sliding seat type accompanying clamping shoe and machining center thereof

A slide-type, worktable technology, applied in small raw hide/large raw hide/leather/fur mechanical processing, leather punching/punching/cutting, raw hide/leather/fur manufacturing equipment, etc. High cost, difficult to apply and other problems, to achieve the effect of reliable clamping, simple mechanism and convenient transposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

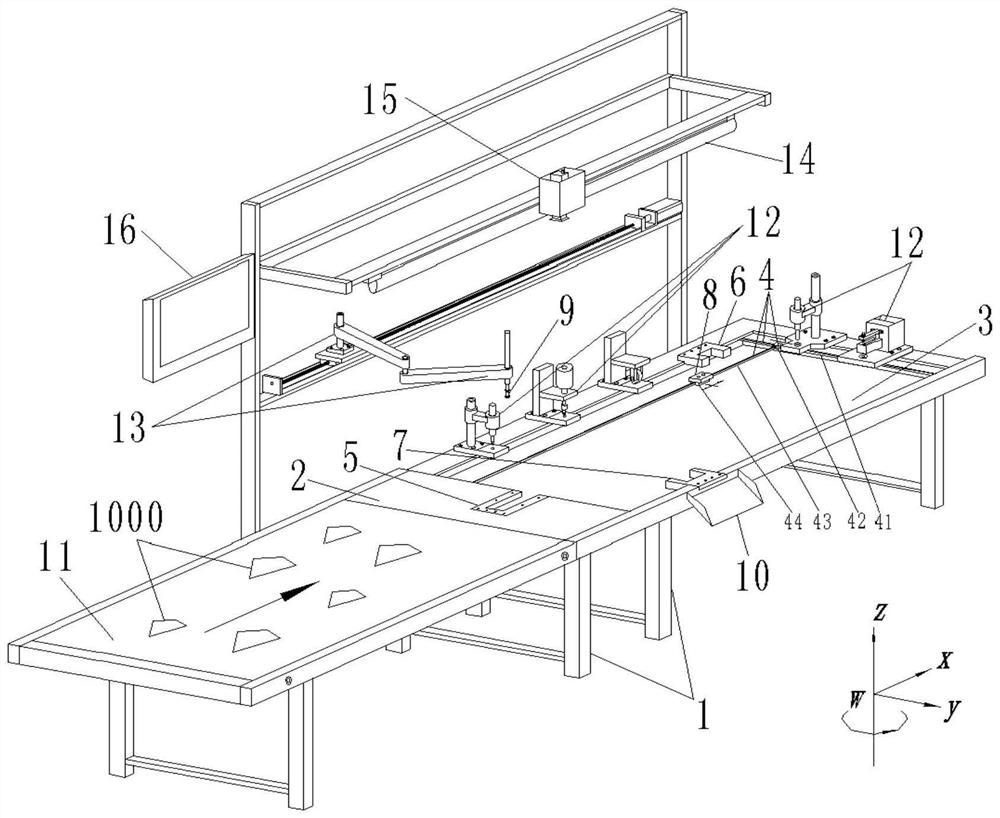

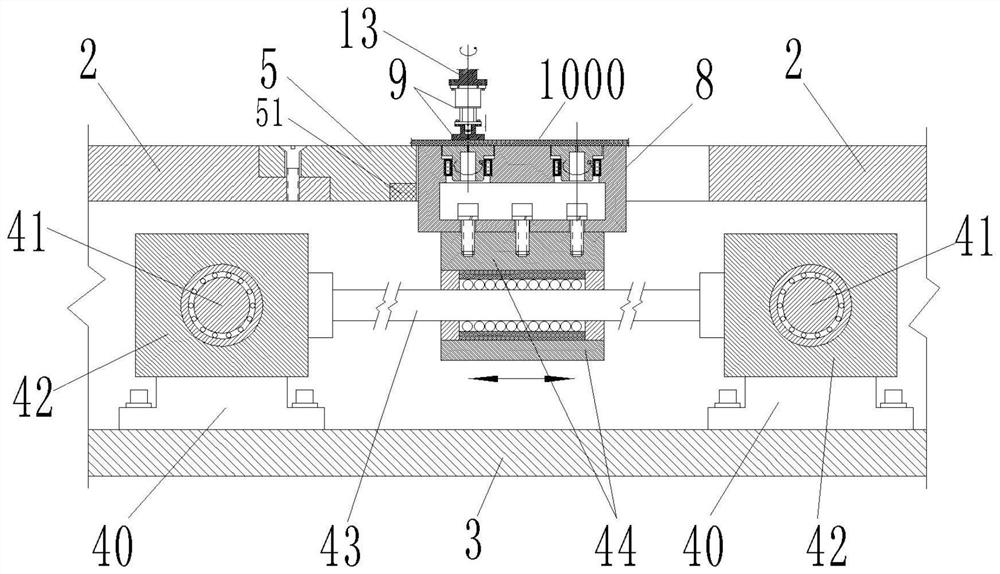

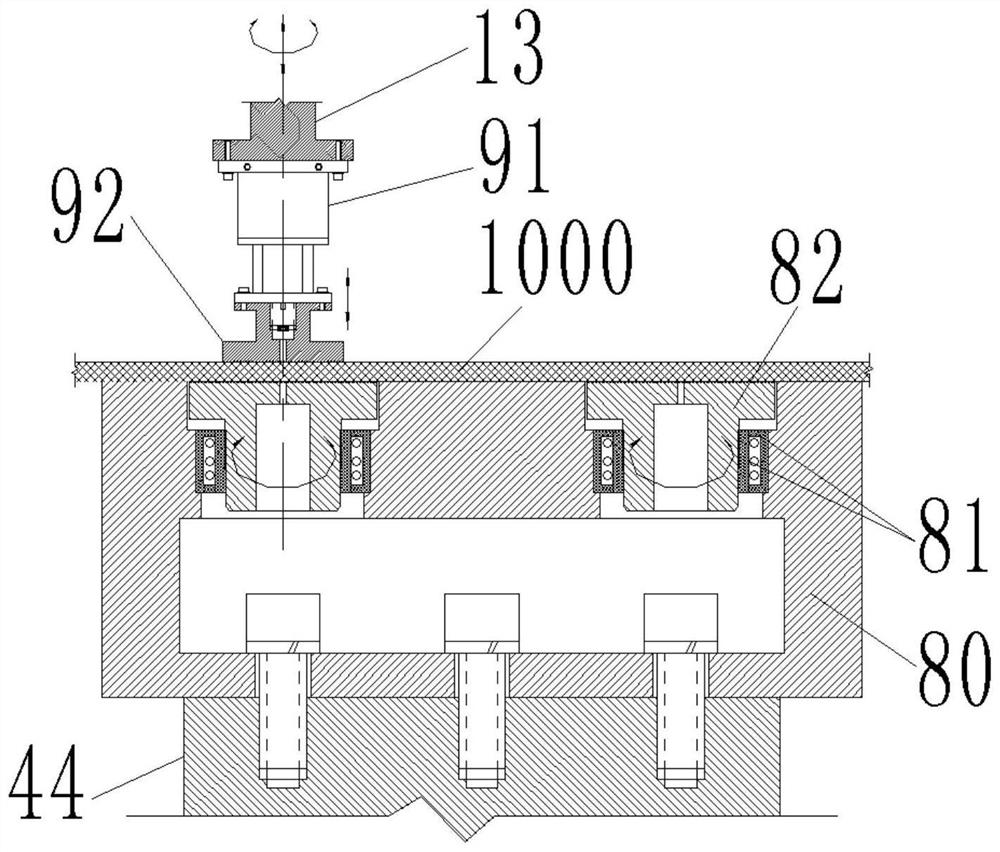

[0028] refer to Figure 1 to Figure 5 , the present embodiment discloses a workbench with a cross-slider type accompanying shoe clip, including a frame 1, a material preparation table 2, a mirror plate 3, a cross sliding module 4, several shoe stacks, accompanying boots 8, and accompanying palms 9 and the discharge port 10, the preparation table 2 and the cross sliding module 4 are respectively arranged on both sides above the frame 1, and the mirror plate 3 is arranged under the cross sliding module 4, and the cross sliding module 4 is used for the accompanying boots 8 in the Horizontal movement on the mirror plate 3, the accompanying shoe 8 can be linked with the accompanying palm 9 to realize the clamping of the workpiece, and the discharge por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com