[0004] The object of the present invention is to provide a kind of

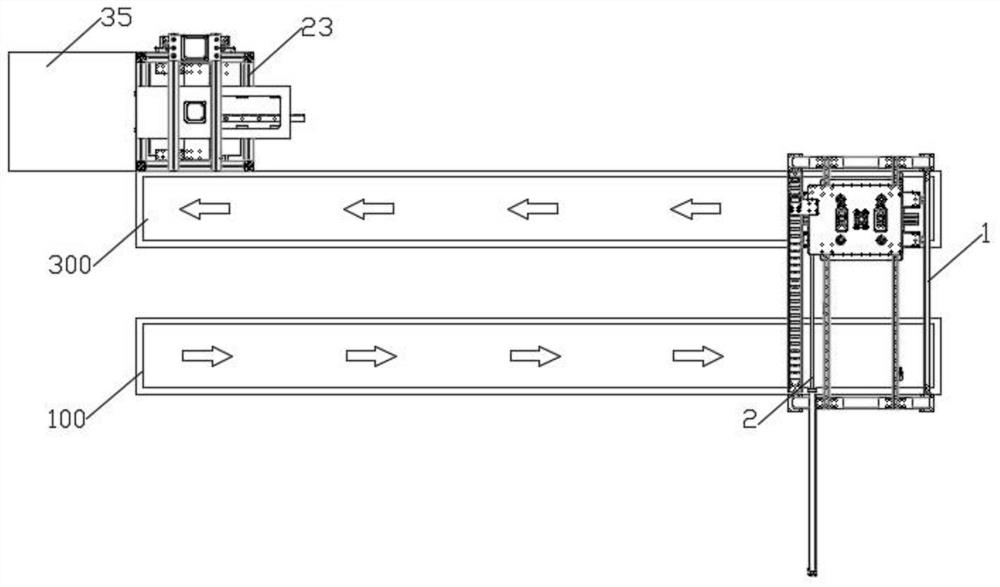

fully automatic circuit board horizontal sinking copper connection VCP electroplating device, solve the following technical problems: (1) by placing circuit boards on the horizontal copper sinking

production line in sequence, the circuit boards are processed through the horizontal copper sinking

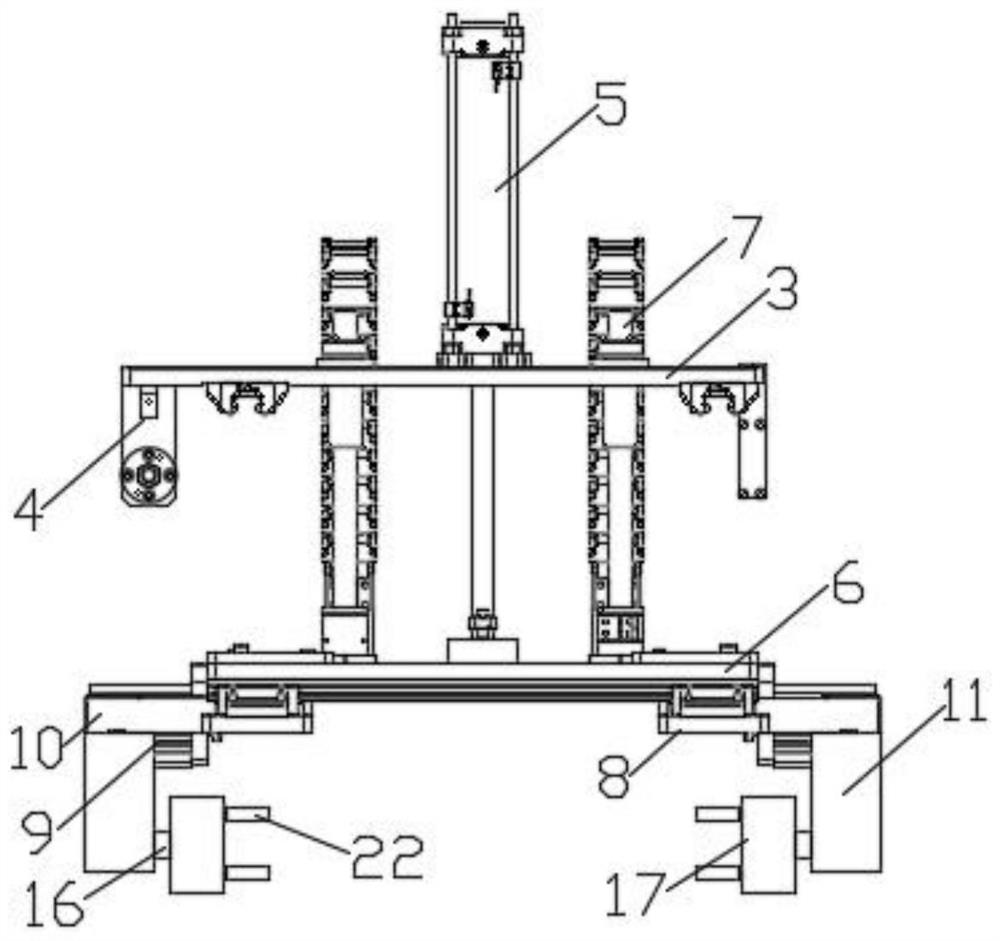

production line Then enter under the transposition frame, open the transposition cylinder, the

piston rod of the transposition cylinder drives the transposition board to move above the circuit board, open two translation cylinders, the

piston rod of the translation cylinder pushes the translation plate, and the two translation plates drive the two connecting plates Move in reverse, open the guide cylinder, the

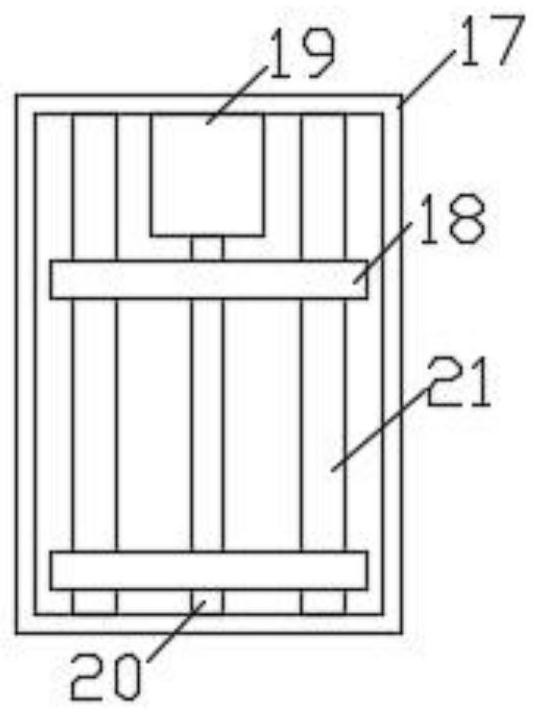

piston rod of the guide cylinder pushes down the lifting plate, the lifting plate drives the two connecting plates down, the two connecting plates drive the four first regulating shells down, and the four first regulating shells descend to the circuit board On both sides, turn on four adjusting motors one, the output shaft of adjusting motor one drives the first screw to rotate, the first screw drives the two first adjusting blocks to move toward each other, the piston rods of the two translational cylinders shrink, and the four first adjusting shells Clamp both sides of the circuit board, through the above structure, the fully automatic circuit board horizontal copper sinking connection VCP electroplating device is set by the transposition frame, so that the circuit board between the horizontal copper sinking production line and the VCP electroplating line can be transposed It will be more convenient, and the whole transposition process is automated without manual participation; (2) open four regulating motors two, and the output shafts of the regulating motors two drive the second lead screw to rotate, and the second lead screw drives the two second regulating blocks to move toward each other, and the two A second adjustment block clamps the upper and lower sides of the circuit board, and then the

piston rod of the guiding cylinder shrinks, the lifting plate rises, the

piston rod of the transposition cylinder pushes the transposition plate, the transposition plate moves to the top of the VCP plating line, and the guiding cylinder The piston rod pushes down the lifting plate, and the circuit board is placed on the VCP electroplating line. Through the above structural settings, the automatic circuit board horizontal sinking copper connection VCP electroplating device can meet the clamping of circuit boards of different thicknesses and widths. Clamping at multiple points on both sides and up and down at the same time will not cause the circuit board to fall during the transposition process; (3) The output shaft of the lifting motor drives the third lead screw to rotate, and the third lead screw drives the support plate The support plate drives the receiving plate to descend, and the receiving plate motor is turned on. The output shaft of the receiving plate motor drives the

bevel gear to rotate. The

bevel gear one cooperates with the

bevel gear two to drive the gear to rotate. In the VCP electroplating line, the circuit board moves to the negative pressure suction cup on the receiving plate after being processed by the VCP electroplating line. The output shaft of the lifting motor drives the third lead screw to rotate in the opposite direction. The receiving board rises, the receiving board drives the circuit board to rise, and the two receiving board cylinders are opened, the piston rod of the receiving board cylinder pushes the fixing bar, and the fixing bar drives the two clamping cylinders to move, and the four clamping cylinders are opened to clamp the piston of the cylinder The lever drives the clamping plate to move, and the four clamping plates clamp the two sides of the circuit board, and the motor for retracting the board is turned on. The output shaft of the motor for retracting the board drives the gear 2 to rotate, and the gear 2 cooperates with the rack 2 to drive the hanging plate to move, and the circuit board is placed on the On the receiving car, through the above structural settings, the fully automatic circuit board horizontal copper connection VCP electroplating device can efficiently place the electroplated circuit board on the receiving car, and the whole process does not require operator participation. Negative pressure suction cup design makes the receiving process of circuit boards more efficient

Login to View More

Login to View More  Login to View More

Login to View More